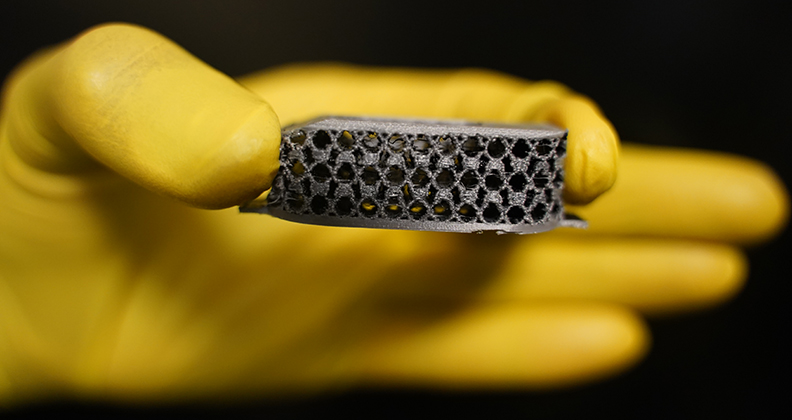

A team of researchers at the University of Pittsburgh Swanson School of Engineering recently announced the development of a patient-specific, 3D-printed, smart metamaterial spine implant. The device leverages highly sophisticated technologies to double as a self-powered sensor that monitors bone healing in the spine. Their findings were published in the Advanced Functional Materials journal.

Amir H. Alavi, Ph.D., is an Assistant Professor of Civil and Environmental Engineering at the University of Pittsburgh and part of the iSMaRT Lab that pioneered the technology. He described the technology as a first-of-its-kind platform that enables them to design smart and stand-alone orthopedic implants with diagnostic, energy harvesting and mechanical tunability functionalities.

“This is clinically significant because surgeons can use the data generated by the implants to directly and precisely assess the bone healing progress,” Dr. Alavi said. “These features can potentially eliminate the need for radiographic imaging techniques, which are usually costly and expose the patients to significant radiation.”

Dr. Alavi described the smart implants as self-sensing constructs that generate their own energy through his team’s patented “meta-tribomaterial” technology, which integrates metamaterial and nanogenerator paradigms.

“Meta-tribomaterials are rationally designed materials systems that are composed of multiple layers of triboelectric auxetic microstructures with self-recovering behavior,” he explained. “The multi-layered metamaterial nature of the designing implants will enable achieving any desired stiffness. The built-in nanogenerator mechanism is the key to generating electrical signals. We have used these self-generated electrical signals for diagnostic purposes. We are very excited about this technology because the sky is the limit for it.

“Just think about the fact that you can use the same self-generated electrical signal for electrical stimulation to accelerate bone healing. This is actually the focus of our current research. No additional electronics or wireless electrical stimulation, or external wireless power transfer will be required. The implant will not only relay information about the healing process but will also help speed it up by itself. We estimate that the generated power density will be sufficient to even empower other implantable electronics, if needed.”

Essentially, the implant functions as a force sensor that monitors healing while ingeniously drawing electrical voltage from spinal loading that is directly proportional to the applied force.

“As the bone heals,” Dr. Alavi said, “the forces on the implant will naturally decrease, and therefore, the generated voltage will decrease. So by tracking the voltage variations, the surgeons and patients can be informed about the bone healing process.”

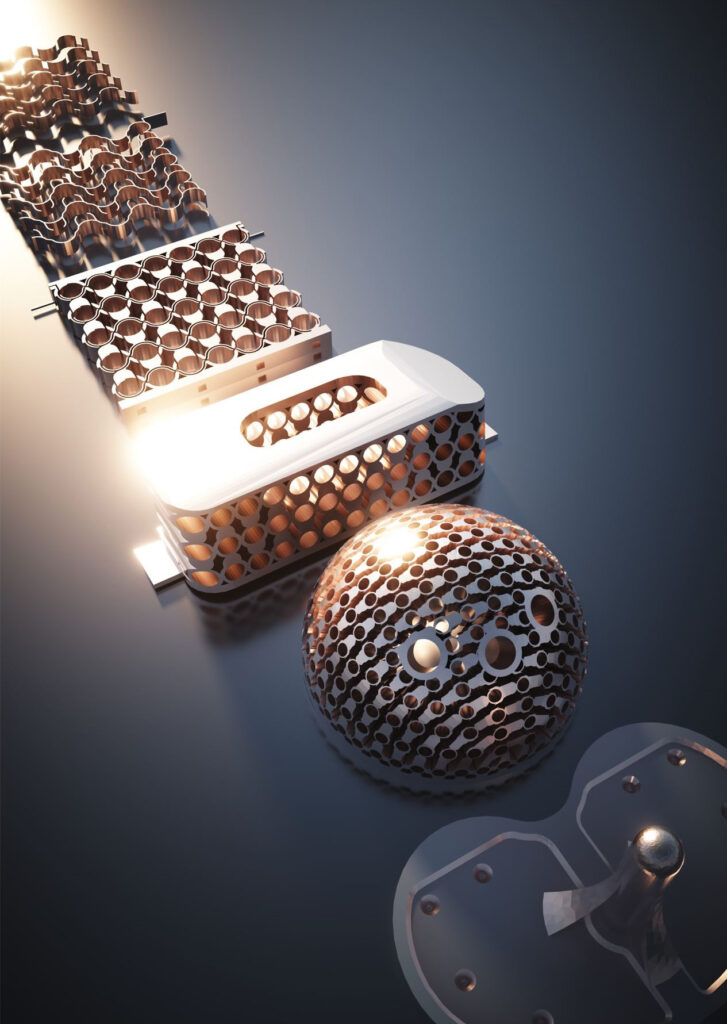

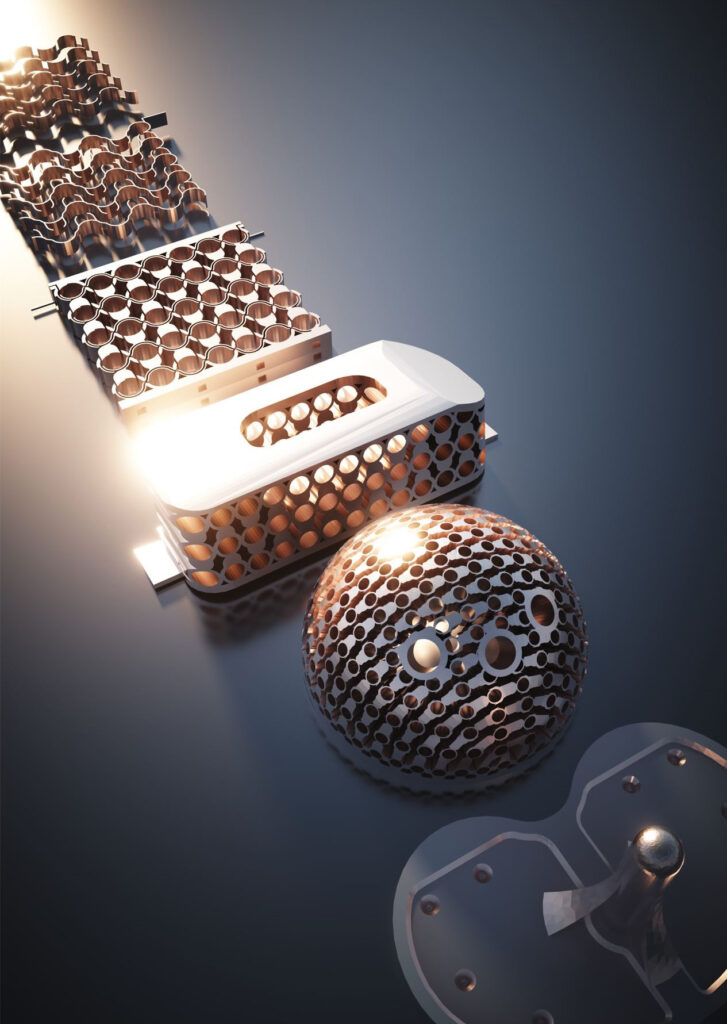

An illustration of potential smart implants using the advanced metamaterial developed by the iSMaRT Lab at the University of Pittsburgh.

The spinal cage is constructed using multiple layers of polylactic acid (PLA) and thermoplastic polyurethane (TPU) polymers. Dr. Avali said his team chose PLA and TPU because of their biocompatibility. “But there are tons of other biocompatible materials (e.g., PDMS, Au, Al, Ti, PEEK) that can be used to design the cage micro-layers depending on the desired electrical and mechanical properties,” he explained.

To 3D print the devices, the team uses multi-material fused deposition modeling and two-photon direct laser writing methods.

Dr. Alavi touted the tunability of the technology, which will enable surgeons to customize the spine implant based on a patient’s unique clinical requirements and anatomical features.

“To give you a simple example, we can use the patient’s bone mineral density to create spinal fusion cages with desired stiffness,” he said. “The beauty of our technology is that these implants only use their constituent components to achieve these advanced functionalities. They don’t need an external power source and bulky electronics.”

Smart implants like the device Dr. Alavi and his team are developing are defined as implantable devices that provide therapeutic benefits and feature diagnostic capabilities. We’re seeing more research in this area of the orthopedic industry, as academia and startups seek to advance implantable technology.

Dr. Alavi predicts that smart implants are going to be vital components of the healthcare system moving forward but cited significant challenges the technology he’s helping to develop aims to address.

“We are already witnessing a glimpse of their huge potential. But they can’t find their wide utility in our daily clinical practice unless we can address two major challenges associated with them,” Dr. Alavi said. “The first challenge is the size of the smart implants for sensor integration. For example, imagine the difficulties associated with integrating multiple circuit boards for sensing, energy storage and wireless communications into the small area of a miniaturized stent.

“The second challenge is the lack of scalable and smart biomaterials for fabricating these devices. We believe that a viable solution to all of these challenges is to create a new class of smart implants that can utilize their ‘constituent components’ to achieve advanced functionalities without using any external power source and bulky electronics.”

When asked what applications the technology could be used for outside of spine, Dr. Alavi highlighted smart cardiac stents with sensing and energy harvesting functionalities as devices that could utilize the same design approach.

Images courtesy of iSMaRT Lab

PM

Patrick McGuire is a BONEZONE Contributor.