Surgeons desire innovative, patient-specific solutions because pre-operative planning and patient-specific instrumentation can lead to reduced time in the operating room and improved patient outcomes.1,2 Additive manufacturing (AM) is well-suited to delivering these instruments, because it enables the production of organically-shaped and optimized products created directly from medical imaging data. In order to help surgeons access the innovation they are looking for, implant manufacturers are adapting with help from AM experts at 3D Systems.

Patient-specific products have become a staple in many orthopedic procedures, with total ankle arthroplasty taking the spotlight as of late. In fact, total ankle arthroplasty is one of the fastest-growing arthroplasty segments, with a compound annual growth rate of 8.4% and $327 million in revenue anticipated by 2026.3

Collaborating to Deliver Precision Healthcare Solutions

There are currently only 10 total ankle systems with U.S. FDA 510(k) clearance in the United States, and three companies with patient-specific technology to accompany the implant. One of these companies is Exactech, which has collaborated with AM solutions leader 3D Systems for more than a decade and received FDA clearance for the Exactech Vantage® Total Ankle System in 2016.

With continued collaboration and joint innovation, the two companies recently launched a new solution to help surgeons reduce time in the operating room with more accurate outcomes by providing patient-specific osteotomy instruments. This solution, Vantage Ankle PSI, combines 3D Systems’ VSP® surgical planning solution and Exactech’s Vantage® Total Ankle System to deliver patient-specific instrumentation intended to streamline surgery.

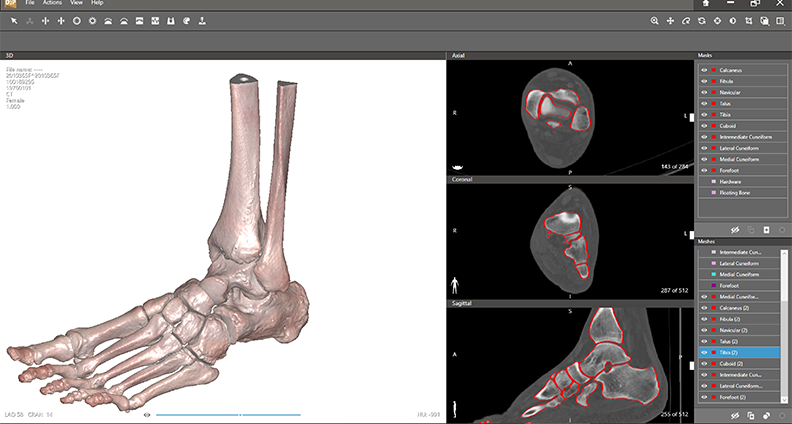

For the development of Vantage Ankle PSI, 3D Systems provided its proven digital workflow, 3D printers, post-processing equipment and regulatory expertise, while Exactech provided implant system aptitude and a skilled surgeon design team. Vantage Ankle PSI instrumentation, similarly to other VSP patient-specific solutions, begins with medical imaging data and support from 3D Systems. 3D Systems’ engineers process the medical imaging data, and design with input from surgeons as part of the surgical planning workflow. The surgeon then receives patient-specific instrumentation, anatomic models and a detailed case report within three weeks based on the pre-planning, which has been shown to increase surgeon confidence during the procedure.4

Design team member Jason Nowak, DMP, FACFAS, of Shasta Orthopaedics, was the first to perform surgery using these instruments, and his feedback reflects the anticipated advantages of the solution: “The unique 3D-printed tibia and talar cutting guides, specifically made for my patient, helped me align and cut each bone with one instrument, saving time and increasing my surgical efficiency,” said Dr. Nowak.

According to Exactech Extremities Vice President Chris Roche, “The Vantage Ankle PSI showcases our commitment to delivering personalized solutions and smart technologies that optimize the way surgeons perform every case. This successful first surgery is a rewarding milestone and a testament to our exclusive partnership with 3D Systems to enhance to total ankle surgery experience.”

3D Systems and Exactech collaborated on the Vantage PSI instrumentation.

Expertise in Additive Manufacturing for Patient-Specific Applications

For the Vantage Ankle PSI offering, 3D Systems designs and 3D prints tibia and talar cutting instrumentation for patients’ unique anatomy, reducing the number of operative steps. The cutting instruments are manufactured using 3D Systems’ selective laser sintering (SLS) technology and DuraForm® ProX® PA, a biocompatible and sterilizable nylon material ideal for personalized surgical instruments. This combination of technology and material provides a repeatable and durable solution for anatomic model and instrument manufacturing.

Submission and clearance of the Vantage Ankle PSI was enabled by experts from 3D Systems’ Application Innovation Group (AIG), who have experience supporting 510(k) clearances and CE Marks on over 100 devices. 3D Systems’ AIG is a global resource equipped with the experience and technology to support AM applications across industries, including healthcare. The AIG can advise and assist on projects at any stage, from application development and frontend engineering, to equipment validation, process validation, part qualification, regulatory consultation and device production. AM technologies are continually evolving with more efficient printers, innovative materials, and an increased presence at point-of-care. In orthopedic surgery, AM provides significant opportunities for collaboration and innovation. As more surgeons benefit from the use of patient-specific surgical planning and instrumentation, the need for medical device companies to expand beyond off-the-shelf implant systems will continue.

3D Systems provides comprehensive products and services, including 3D printers, print materials, software and on-demand manufacturing services for the healthcare industry.

1. Patel A, Levine J, Brecht L, Saadeh P, Hirsch DL: Digital technologies in mandibular pathology and reconstruction. Atlas Oral Maxillofacial Surg Clin N Am 20:95-106, 2012

2. Roser SM, Ramachandra S, Blair H, Grist W, Carlson GW, Christensen AM, Weimer KA, Steed MB: The accuracy of virtual surgical planning in free fibula mandibular reconstruction: comparison of planned and final results. J Oral Maxillofac Surg 68:2824-2832, 2010

3. https://www.medgadget.com/2019/09/total-ankle-replacement-market-2019-overview-industry-opportunities-and-outlook-to-2026.html

4. McCormick S, Drew S: Virtual model surgery for efficient planning and surgical performance. J Oral Maxillofac Surg 69:638-644, 2011