-

Orchid Orthopedic Solutions

Corporate Headquarters

1489 Cedar St

Holt, MI

48842

United States - 10 Facilities

- 517-694-2300

- 2000+ employees

- Founded in 2005

- Operating in Europe, North America

- Visit Website

Changes saved

- Additive Manufacturing

- Logistics/Supply Chain

- Manufacturing

- Packaging

- Product Development

- Surface Preparation/Treatments

Orchid is a leader in manufacturing solutions for the orthopedic market. We offer the broadest portfolio in the industry, ranging from additive manufacturing, forging, casting, machining and bone in-growth coatings. We offer end-to-end solutions for all steps in the supply chain. Orchid specializes in implants, instruments, and innovative technologies for joint reconstruction, hips, knees, spine, trauma, and extremities.

With a sole focus in medical devices, Orchid specializes in implants, instruments, and innovative technologies for the following markets:

• Joint Reconstruction (Knee, Hip, Shoulder)

• Extremities

• Spine

• Trauma

MAJOR MARKETS SERVED

With a sole focus in medical devices, Orchid specializes in implants, instruments, and innovative technologies for the following markets:

• Joint Reconstruction (Knee, Hip, Shoulder)

• Extremities

• Spine

• Trauma

With a comprehensive portfolio of capabilities required to build orthopedic implants and instruments, Orchid Supply+ offers program management of your entire supply chain with one purchase order. We can help manage your supply chain by providing resources, managing suppliers, maintaining partnerships and maximizing your cash flow. This allows you to:

Simplify Your Supply Chain

Project management from design through manufacturing and packaging.

- Reduced supplier touch-points

- Reliable product availability

- Consolidated planning and product management

Improve Operational Efficiency

Manufacturing and inventory management enables:

- Reduced excess inventory

- Increased cash flow

- Long-term cost savings

Enable Innovation

Full project sourcing allows you to focus on new products.

- Align your resources to innovation

- Focus on improved patient outcomes

- Generate a larger pipeline of new products

ORCHID SUPPLY+: Leverage Orchid to Manage Your Value Stream

With a comprehensive portfolio of capabilities required to build orthopedic implants and instruments, Orchid Supply+ offers program management of your entire supply chain with one purchase order. We can help manage your supply chain by providing resources, managing suppliers, maintaining partnerships and maximizing your cash flow. This allows you to:

Simplify Your Supply Chain

Project management from design through manufacturing and packaging.

- Reduced supplier touch-points

- Reliable product availability

- Consolidated planning and product management

Improve Operational Efficiency

Manufacturing and inventory management enables:

- Reduced excess inventory

- Increased cash flow

- Long-term cost savings

Enable Innovation

Full project sourcing allows you to focus on new products.

- Align your resources to innovation

- Focus on improved patient outcomes

- Generate a larger pipeline of new products

ADDITIVE MANUFACTURING (3D PRINTING)

Move efficiently to large joint 3D printing by partnering with experts in orthopedic manufacturing. The latest in additive manufacturing, electron beam melting (EBM), enables cost-effective high-volume production of large joint implants and trials. Enable innovation without limitation and with zero compromises.

FORGING

We specialize in products made from titanium, CoCr, stainless steel, and zirconium. Our forging processes result in precisely crafted products that are exceptionally strong and durable, requiring little or no machining or finishing and providing significant cost savings.

CASTING

Our capabilities include air and vacuum investment casting and complete product finishing. Both CoCr and stainless steel alloys are used. Robotic wax assembly and shelling systems, digital X-ray, dedicated manufacturing teams, and a skilled workforce create quality castings that meet or exceed design specs.

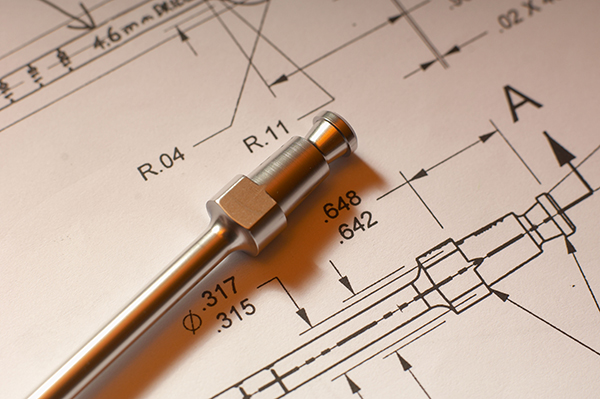

MACHINING

We have proven in-depth knowledge and exceptional performance in the machining of implants and instrumentation. We offer automation for a variety of materials and Swiss-turning, multi-axis milling, lathing, turning, and grinding solutions to help you build medical devices and bring your product to life. We can manage your supply chain to give you a complete one-stop-shop solution.

COMPLEX INSTRUMENT ASSEMBLIES

One of the most difficult manufacturing jobs is the fabrication and assembly of complex instrumentation. Whether your instrument is designed with one or multiple components, we deliver reliable results.

BONE IN-GROWTH TECHNOLOGIES

We offer multiple cementless coating options for your orthopedic implants. Partner with us for customizable options to meet your needs.

• Hydroxylapatite (HA)

• Asymmatrix®

• Titanium PlasmaSpray (TPS)

• Fortify™

• Spherical Bead

• Thin TPS

Manufacturing

ADDITIVE MANUFACTURING (3D PRINTING)

Move efficiently to large joint 3D printing by partnering with experts in orthopedic manufacturing. The latest in additive manufacturing, electron beam melting (EBM), enables cost-effective high-volume production of large joint implants and trials. Enable innovation without limitation and with zero compromises.

FORGING

We specialize in products made from titanium, CoCr, stainless steel, and zirconium. Our forging processes result in precisely crafted products that are exceptionally strong and durable, requiring little or no machining or finishing and providing significant cost savings.

CASTING

Our capabilities include air and vacuum investment casting and complete product finishing. Both CoCr and stainless steel alloys are used. Robotic wax assembly and shelling systems, digital X-ray, dedicated manufacturing teams, and a skilled workforce create quality castings that meet or exceed design specs.

MACHINING

We have proven in-depth knowledge and exceptional performance in the machining of implants and instrumentation. We offer automation for a variety of materials and Swiss-turning, multi-axis milling, lathing, turning, and grinding solutions to help you build medical devices and bring your product to life. We can manage your supply chain to give you a complete one-stop-shop solution.

COMPLEX INSTRUMENT ASSEMBLIES

One of the most difficult manufacturing jobs is the fabrication and assembly of complex instrumentation. Whether your instrument is designed with one or multiple components, we deliver reliable results.

BONE IN-GROWTH TECHNOLOGIES

We offer multiple cementless coating options for your orthopedic implants. Partner with us for customizable options to meet your needs.

• Hydroxylapatite (HA)

• Asymmatrix®

• Titanium PlasmaSpray (TPS)

• Fortify™

• Spherical Bead

• Thin TPS

Mason, MI

United States

Arab, AL

United States

Bridgeport, MI

United States

Baden-Dättwil, Aargau

Switzerland

Farmington Hills, MI

United States

Holt, MI

United States

Suite 1

Memphis, TN

United States

Oregon City, OR

United States

Santa Ana, CA

United States

Sheffield

United Kingdom