-

Oberg Medical

2301 Silverville Rd

Freeport, PA

16229

United States - 5 US-based facilities

- 724-295-2121

- 700+ employees

- Founded in 1948

- Operating in North America

- Visit Website

Vice President of Sales and Market Development

Changes saved

- Instruments

- Manufacturing

- Materials/Bio and Performance

- Materials/Metals

- Product Development

- Surface Preparation/Treatments

- Testing

Oberg Medical is a trusted precision machining, stamping and tooling contract manufacturing partner supporting medical device OEMs. We deliver metal and plastic implants, instruments, assemblies, surface enhancement and automation solutions for Orthopedic, Spine, Extremity, Endoscopic/Laparoscopic, & Cardiac Rhythm Management markets. Rapid prototyping, engineering + DFM support get your devices to market fast. Five U.S.-based manufacturing facilities in PA, CT and Chicago. ISO 13485 & FDA Reg.

Over 90 validated machines

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss Turn

Machining/Turning/EDM

Over 90 validated machines

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss Turn

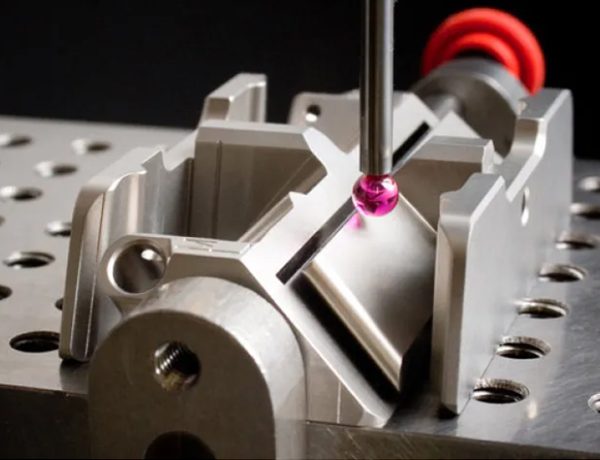

Over 35 validated machines

- Surface/Centerless

- Jig/Advanced MDP®

- Lapping

- Surface Preparation

- Robotic Assisted Polishing

Precision Grinding

Over 35 validated machines

- Surface/Centerless

- Jig/Advanced MDP®

- Lapping

- Surface Preparation

- Robotic Assisted Polishing

50+ presses from 5 to 400 tons

In 1948, Oberg revolutionized the industry by pioneering the use of tungsten carbide in our stamping dies for long-running, high-precision manufacturing applications. This harder-than-steel material created longer-life tooling that reduced overall production costs, improved accuracy and forever changed the industry.

Tooling and Stamping

50+ presses from 5 to 400 tons

In 1948, Oberg revolutionized the industry by pioneering the use of tungsten carbide in our stamping dies for long-running, high-precision manufacturing applications. This harder-than-steel material created longer-life tooling that reduced overall production costs, improved accuracy and forever changed the industry.

- Heat Treating

- Cryogenics Welding (Laser + TIG)

- Electropolish, Passivation

- Lapping, Deburring

- Cleaning + Passivation

- Laser Marking

- Pad Printing

- Assembly/Non-Sterile Packaging

- Bead Blasting/Metal Finishing

Special/Secondary Processes

- Heat Treating

- Cryogenics Welding (Laser + TIG)

- Electropolish, Passivation

- Lapping, Deburring

- Cleaning + Passivation

- Laser Marking

- Pad Printing

- Assembly/Non-Sterile Packaging

- Bead Blasting/Metal Finishing

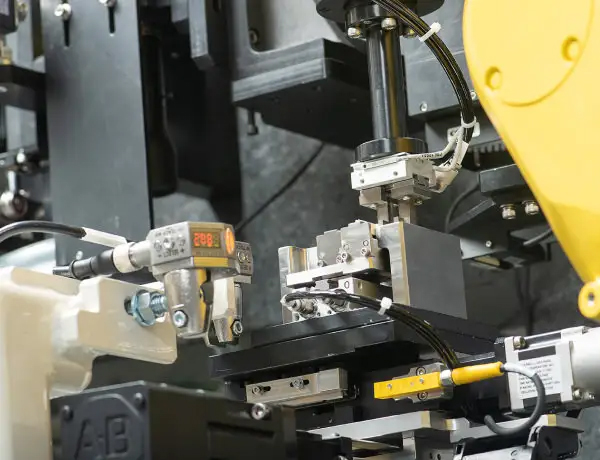

- Semi and Fully-Automated

- Quick-Turn Cells

- Gun Drilling

Dedicated Work Cells

- Semi and Fully-Automated

- Quick-Turn Cells

- Gun Drilling

Your Products Get To Market Faster – We can help you accelerate new products to market. Scale manufacturing into the production volumes you need or expand capacity for a legacy product.

Innovation Focused – Using our design-for-manufacturing methodology, our project managers, manufacturing engineers and quality engineers collaborate with your project teams to develop high-quality products that meet your customers’ needs in the most cost-effective manner and the shortest time to market.

The Capacity You Need – We’ve recently expanded our manufacturing floor space by an additional 80,000 square feet and are again planning to add more capacity. Our industry-leading apprenticeship program is designed to attract and develop the skilled machinists needed to support our customers. Facilities in Pittsburgh, Chicago and Connecticut offer the people, equipment, capacity and passion to cost-effectively meet your growth needs or help consolidate your supply chain.

Oberg Advantage

Your Products Get To Market Faster – We can help you accelerate new products to market. Scale manufacturing into the production volumes you need or expand capacity for a legacy product.

Innovation Focused – Using our design-for-manufacturing methodology, our project managers, manufacturing engineers and quality engineers collaborate with your project teams to develop high-quality products that meet your customers’ needs in the most cost-effective manner and the shortest time to market.

The Capacity You Need – We’ve recently expanded our manufacturing floor space by an additional 80,000 square feet and are again planning to add more capacity. Our industry-leading apprenticeship program is designed to attract and develop the skilled machinists needed to support our customers. Facilities in Pittsburgh, Chicago and Connecticut offer the people, equipment, capacity and passion to cost-effectively meet your growth needs or help consolidate your supply chain.

P.O. Box 368

Freeport, PA

United States

Sarver, PA

United States

Sarver, PA

United States

Chicago, IL

United States

Wallingford, CT

United States