-

Micropulse Inc

5865 E State Rd 14

Columbia City, IN

46725

United States - 270,000 sq. ft., 1 Facility

- 260-625-3304

- 525++ employees

- Founded in 1988

- Operating in North America

- Visit Website

Director of Marketing

Changes saved

- Additive Manufacturing

- Cases & Trays

- Instruments

- Manufacturing

- Packaging

- Surface Preparation/Treatments

Micropulse is a privately held contract manufacturer of medical devices headquartered in Columbia City, Indiana. Since transitioning to 100% orthopedics in 2003, our 515+ employees have been part of numerous expansions, which combine for 270,000+ square feet under one roof. Core competencies include instrument, implant, and case and tray manufacturing as well as sterile packaging.

The Micropulse instrument team provides support for needs that vary from single-piece components, complex, multi-component instruments, and large-scale broach family launches across all orthopedic market segments. A diverse machining foundation, skilled staff, and mature QMS platform allow Micropulse to strategically grow with an established customer base in an industry known for its regulatory demands.

Instruments

The Micropulse instrument team provides support for needs that vary from single-piece components, complex, multi-component instruments, and large-scale broach family launches across all orthopedic market segments. A diverse machining foundation, skilled staff, and mature QMS platform allow Micropulse to strategically grow with an established customer base in an industry known for its regulatory demands.

The Micropulse implant team serves the spine, trauma, and upper and lower extremity markets. A focus to automate machining processes has allowed for continued growth and expansion of this product line. A diverse machining foundation, skilled staff, and a mature QMS platform allows Micropulse to strategically grow with an established customer base in an industry known for its regulatory demands.

Implants

The Micropulse implant team serves the spine, trauma, and upper and lower extremity markets. A focus to automate machining processes has allowed for continued growth and expansion of this product line. A diverse machining foundation, skilled staff, and a mature QMS platform allows Micropulse to strategically grow with an established customer base in an industry known for its regulatory demands.

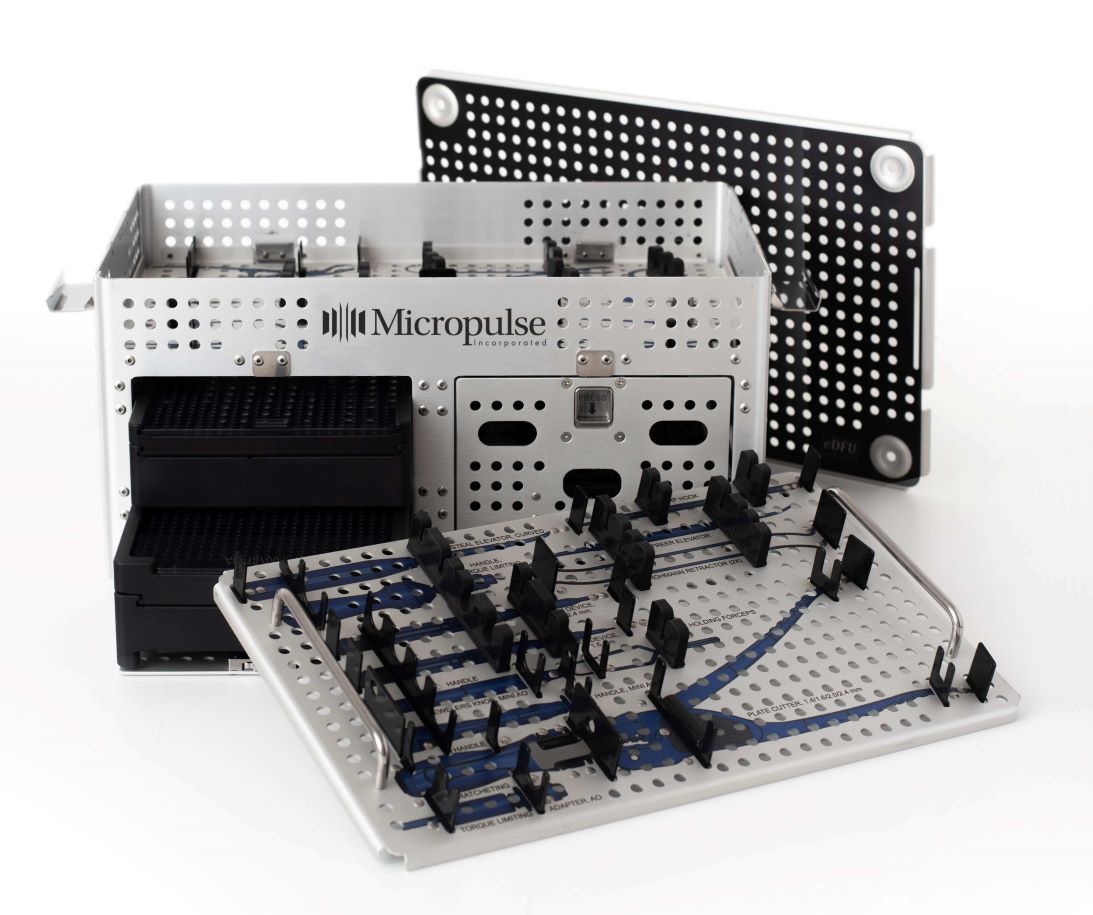

The Case and Tray team custom designs and manufactures orthopedic sterilization cases. Nearly all capabilities are completed in-house which includes case, caddy, bracket, and lid manufacturing as well as screen-printing, nylon coating, finishing, and packaging. All validations and processes are tailored specifically to the orthopedic industry which provides our customers with a product that is designed, built, and inspected to withstand the rigorous requirements of the orthopedic industry.

Cases & Trays

The Case and Tray team custom designs and manufactures orthopedic sterilization cases. Nearly all capabilities are completed in-house which includes case, caddy, bracket, and lid manufacturing as well as screen-printing, nylon coating, finishing, and packaging. All validations and processes are tailored specifically to the orthopedic industry which provides our customers with a product that is designed, built, and inspected to withstand the rigorous requirements of the orthopedic industry.

The Packaging team provides both sterile and non-sterile packaging for orthopedic implants and instruments. Services available include packaging design, testing, and validations. Micropulse offers pre-validated MICROSEAL® options, as well as, custom packaging solutions exclusively for the orthopedic industry. Our services provide a convenient, competitive, and timely solution when it comes to getting your product to market.

Sterile Packaging

The Packaging team provides both sterile and non-sterile packaging for orthopedic implants and instruments. Services available include packaging design, testing, and validations. Micropulse offers pre-validated MICROSEAL® options, as well as, custom packaging solutions exclusively for the orthopedic industry. Our services provide a convenient, competitive, and timely solution when it comes to getting your product to market.

We have an open door policy at Micropulse. Customers and interested orthopedic companies are highly encouraged to visit our facility and meet our team. We’re proud of our 260,000-square-foot facility featuring high-speed machining, robotic part handling, and new technologies that allow us to rapidly adjust to market changes and customer needs. Micropulse is located near Columbia City, Indiana, about 30 minutes from Warsaw.

Visit Our Facility

We have an open door policy at Micropulse. Customers and interested orthopedic companies are highly encouraged to visit our facility and meet our team. We’re proud of our 260,000-square-foot facility featuring high-speed machining, robotic part handling, and new technologies that allow us to rapidly adjust to market changes and customer needs. Micropulse is located near Columbia City, Indiana, about 30 minutes from Warsaw.

Columbia City, IN 46725

United States