-

Marmon Medical Manufacturing

181 West Madison Street

Suite 2500

Chicago, Illinois

60602-4510

United States - 200,000 square feet, 5 facilities

- 312-372-9500

- 600+ employees

- Founded in 1989

- Operating in Asia, North America

- Visit Website

Director, Marketing & Strategy

VP, Sales

Changes saved

- Component Parts

- Instruments

- Logistics/Supply Chain

- Manufacturing

- Packaging

- Product Development

- Sterilization

- Surface Preparation/Treatments

At Marmon Medical Manufacturing, a Berkshire Hathaway company established with the purpose of advancing patient care, we are committed to nurturing long-term partnerships with leading orthopedic companies. Built on the combined expertise of Precision Edge Surgical Products and Apex Tools & Orthopedics, our teams specialize in complex surgical products and deliver optimized solutions, elevate engineering designs, and streamline production with superior quality, consistency, and on time delivery.

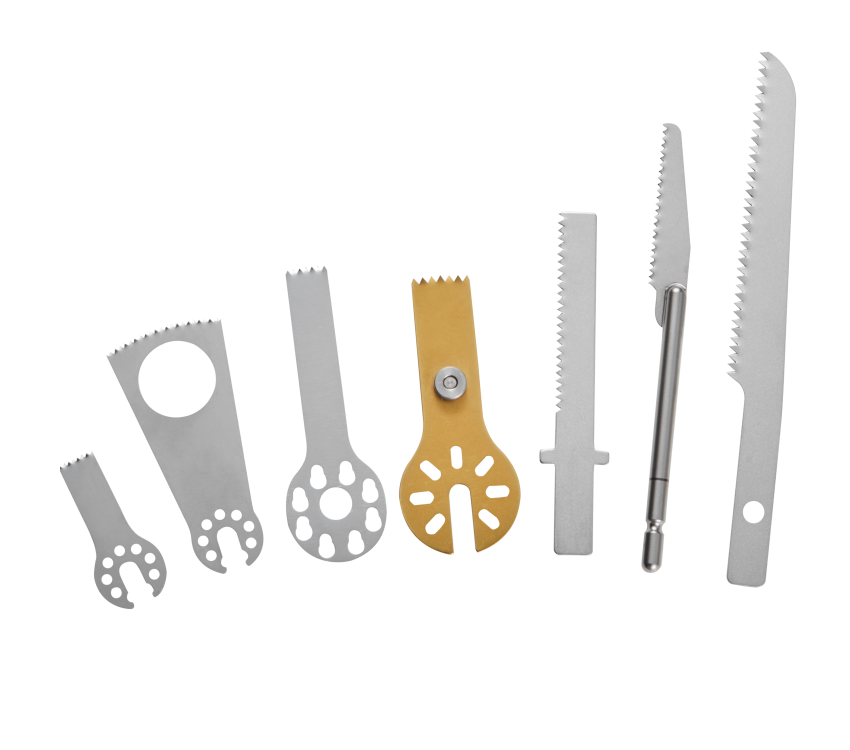

Drills: We manufacture millions of cutting tools each year. Our grinding and gun-drilling equipment ensures the finest products, with the sharpest edges. From thin walls to long lengths, we can do it. Our proprietary know-how allows us to outperform other manufacturers.

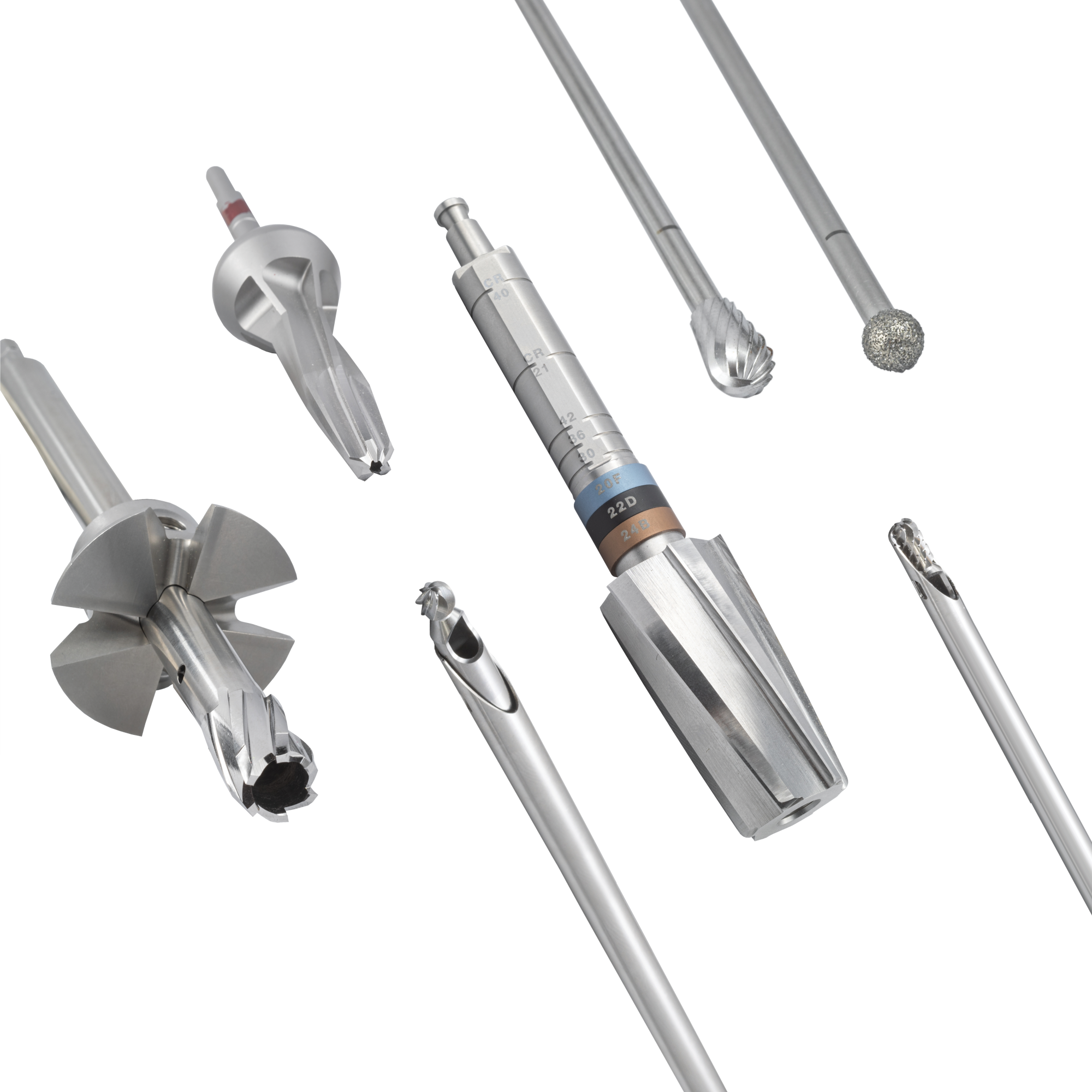

Burs & Shavers: From diamond coated burs that cut and shape bone and tip and tube assembly shaver burs for soft tissue repair, to our cannulated drills, taps and reamers, we support the design and production of every kind. We can manage entire programs from manufacturing, injection molding, assembly, sterilization and final packaging.

Reamers: Our dramatic focus on cutting geometries starts at the tip of the tool, let us help you tune the flute design that provides the speed and effectiveness your specific application demands.

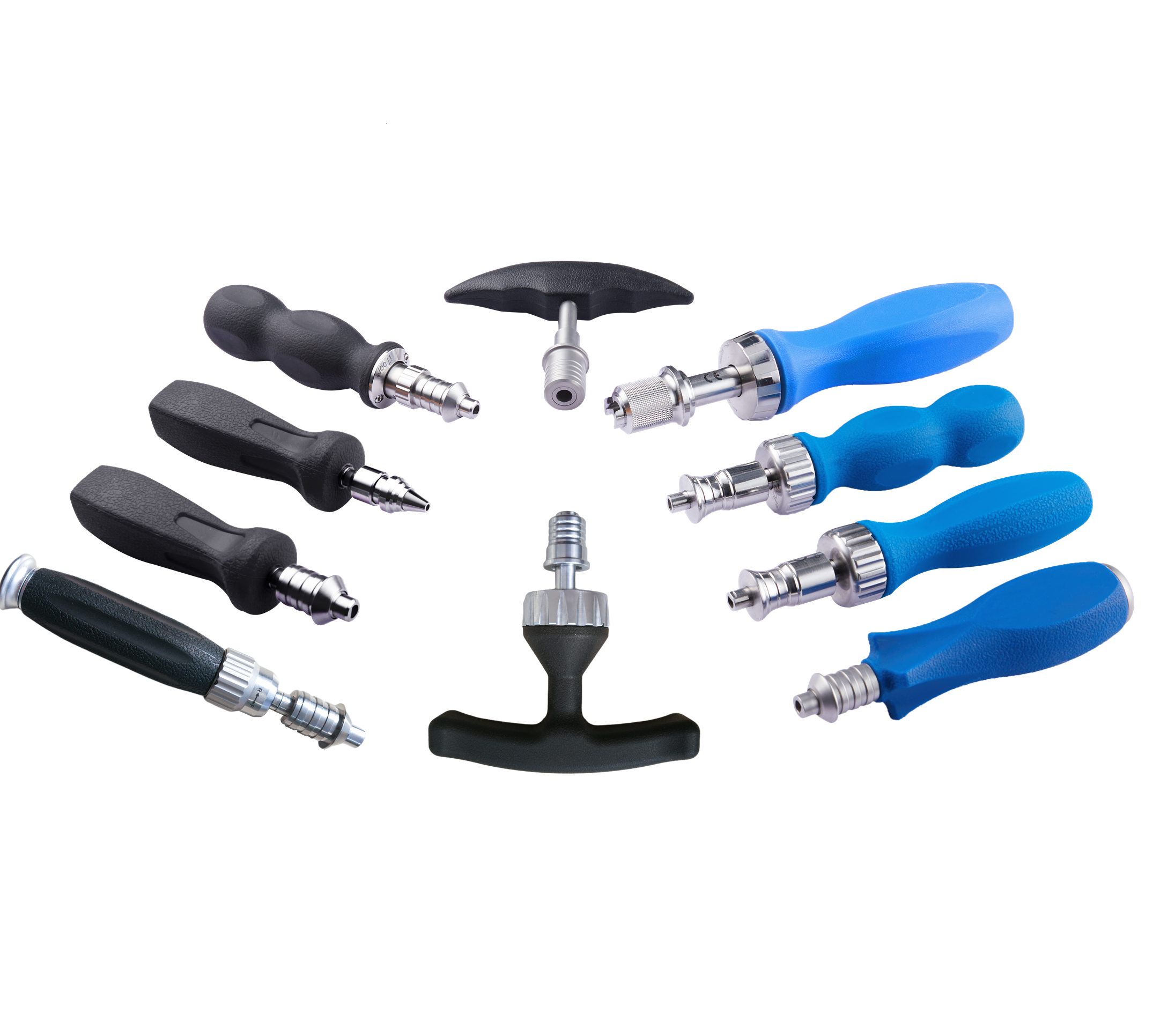

Instruments: With an entire team focused on instruments, we have dedicated equipment for custom and standard instrument manufacturing. We understand the challenges of complex instrument designs but have the capabilities to support small and large production requirements and assembly.

Prototyping / Specials and Instrumentation: Bring us your idea and let us help you bring it to fruition. We’ll develop processes that focus on cost containment, giving you the product you want at a price you’ll like.

Cutting Tools & Instruments

Drills: We manufacture millions of cutting tools each year. Our grinding and gun-drilling equipment ensures the finest products, with the sharpest edges. From thin walls to long lengths, we can do it. Our proprietary know-how allows us to outperform other manufacturers.

Burs & Shavers: From diamond coated burs that cut and shape bone and tip and tube assembly shaver burs for soft tissue repair, to our cannulated drills, taps and reamers, we support the design and production of every kind. We can manage entire programs from manufacturing, injection molding, assembly, sterilization and final packaging.

Reamers: Our dramatic focus on cutting geometries starts at the tip of the tool, let us help you tune the flute design that provides the speed and effectiveness your specific application demands.

Instruments: With an entire team focused on instruments, we have dedicated equipment for custom and standard instrument manufacturing. We understand the challenges of complex instrument designs but have the capabilities to support small and large production requirements and assembly.

Prototyping / Specials and Instrumentation: Bring us your idea and let us help you bring it to fruition. We’ll develop processes that focus on cost containment, giving you the product you want at a price you’ll like.

Performance Evaluation / Cut Testing: Precision Edge was founded on the premise of producing the sharpest cutting edges in the industry. Our stringent benchmarking and testing ensure we hold onto that title.

- Design Input For Cutting Geometries

- Design For Manufacturability (DFM)

- Cutting Performance Testing and Evaluation

- Reverse Engineering

- Tooling Design and Manufacturing

- Rapid prototyping

Engineering Excellence

Performance Evaluation / Cut Testing: Precision Edge was founded on the premise of producing the sharpest cutting edges in the industry. Our stringent benchmarking and testing ensure we hold onto that title.

- Design Input For Cutting Geometries

- Design For Manufacturability (DFM)

- Cutting Performance Testing and Evaluation

- Reverse Engineering

- Tooling Design and Manufacturing

- Rapid prototyping

Often overlooked but always important, we help with custom packaging and labeling, barcoding, inventory management, and more.

- Dedicated Customer Service Representative (CSR)

- Always by your side: One point of contact for all communication.

- Monitors inventory levels, ensures product availability

- Safety stock programs

- Vendor Managed Inventory

- Blanket Release Programs

- Visibility to Customer Inventory

- Consignment Inventory

- Bar Coding

- Custom Packaging & Labeling

- Environment Controlled Pack Room

- ISO Class 8 Clean Room

- Assembly

- Personalized Account Servicing

Value-Added Services

Often overlooked but always important, we help with custom packaging and labeling, barcoding, inventory management, and more.

- Dedicated Customer Service Representative (CSR)

- Always by your side: One point of contact for all communication.

- Monitors inventory levels, ensures product availability

- Safety stock programs

- Vendor Managed Inventory

- Blanket Release Programs

- Visibility to Customer Inventory

- Consignment Inventory

- Bar Coding

- Custom Packaging & Labeling

- Environment Controlled Pack Room

- ISO Class 8 Clean Room

- Assembly

- Personalized Account Servicing

To make the best products, we need the right machines. Here’s a sampling of what you’ll find in our facilities:

- CNC Machining Centers with 4th axis simultaneous capabilities

- 8 axis CNC Grinders

- CNC Swiss Lathes

- Gun Drilling

- Wire EDM

- Laser Etching

- Centerless Grinding

- O.D. Grinding

- Surface Grinding

- Laser Cutting (Flat / Tubing)

- Welding (Laser, TIG, MIG & Silver Soldering)

- Blasting

- Electropolish

- Passivation

Machine Capabilities

To make the best products, we need the right machines. Here’s a sampling of what you’ll find in our facilities:

- CNC Machining Centers with 4th axis simultaneous capabilities

- 8 axis CNC Grinders

- CNC Swiss Lathes

- Gun Drilling

- Wire EDM

- Laser Etching

- Centerless Grinding

- O.D. Grinding

- Surface Grinding

- Laser Cutting (Flat / Tubing)

- Welding (Laser, TIG, MIG & Silver Soldering)

- Blasting

- Electropolish

- Passivation