-

EXALTA Group

89 S Commerce Way

Bethlehem, PA

18017

United States - 700,000 square feet, 12 facilities

- (866) 761-0933

- 1600+ employees

- Founded in 2000

- Operating in Asia, Europe, Global, North America

- Visit Website

CEO

Changes saved

- Cases & Trays

- Component Parts

- Instruments

- Logistics/Supply Chain

- Manufacturing

- Materials/Metals

- Packaging

- Product Development

- Regulatory/Quality Assurance

- Surface Preparation/Treatments

- Testing

Discover the power of EXALTA, born from the fusion of Intech, Tyber Medical, and Resolve Surgical to deliver global orthopedic solutions. With a worldwide footprint, we offer precision contract-manufacturing as well as turnkey, 510(k)- and EUMDR- cleared systems that help OEMs accelerate time-to-market. As your manufacturer of record, we reduce risk, streamline complexity, and bring innovation to life, faster.

From blueprints to large scale production

We are dedicated to providing you with orthopedic instruments and implants from proof of concept to full scale production. Let us help you bring your ideas to life, with innovation, excellence and a smile.

Build-to-Print Implants & Instruments

From blueprints to large scale production

We are dedicated to providing you with orthopedic instruments and implants from proof of concept to full scale production. Let us help you bring your ideas to life, with innovation, excellence and a smile.

Delivering the impossible, one layer at a time

We offer unparalleled design freedom, enabling the creation of intricate, customized, and highly innovative products. This level of customization not only benefits patients by providing tailored solutions but also streamlines manufacturing through reduced waste. Embrace our additive manufacturing solutions to unlock a world of design possibilities, improved patient outcomes, and reduced manufacturing overhead.

Additive Manufacturing (DMLS)

Delivering the impossible, one layer at a time

We offer unparalleled design freedom, enabling the creation of intricate, customized, and highly innovative products. This level of customization not only benefits patients by providing tailored solutions but also streamlines manufacturing through reduced waste. Embrace our additive manufacturing solutions to unlock a world of design possibilities, improved patient outcomes, and reduced manufacturing overhead.

Prototype-dedicated cells

Our innovative in-house prototyping units worldwide are designed to ensure rapid turnaround of production-quality orthopedic instruments, handles and implants.

The Prototype Garage

Prototype-dedicated cells

Our innovative in-house prototyping units worldwide are designed to ensure rapid turnaround of production-quality orthopedic instruments, handles and implants.

A firm grip on innovation

Comfort, Aesthetics, Precision, Customization. Our range of high-tech ergonomic silicone handles are designed to deliver the most seamless surgical experiences.

Handles

A firm grip on innovation

Comfort, Aesthetics, Precision, Customization. Our range of high-tech ergonomic silicone handles are designed to deliver the most seamless surgical experiences.

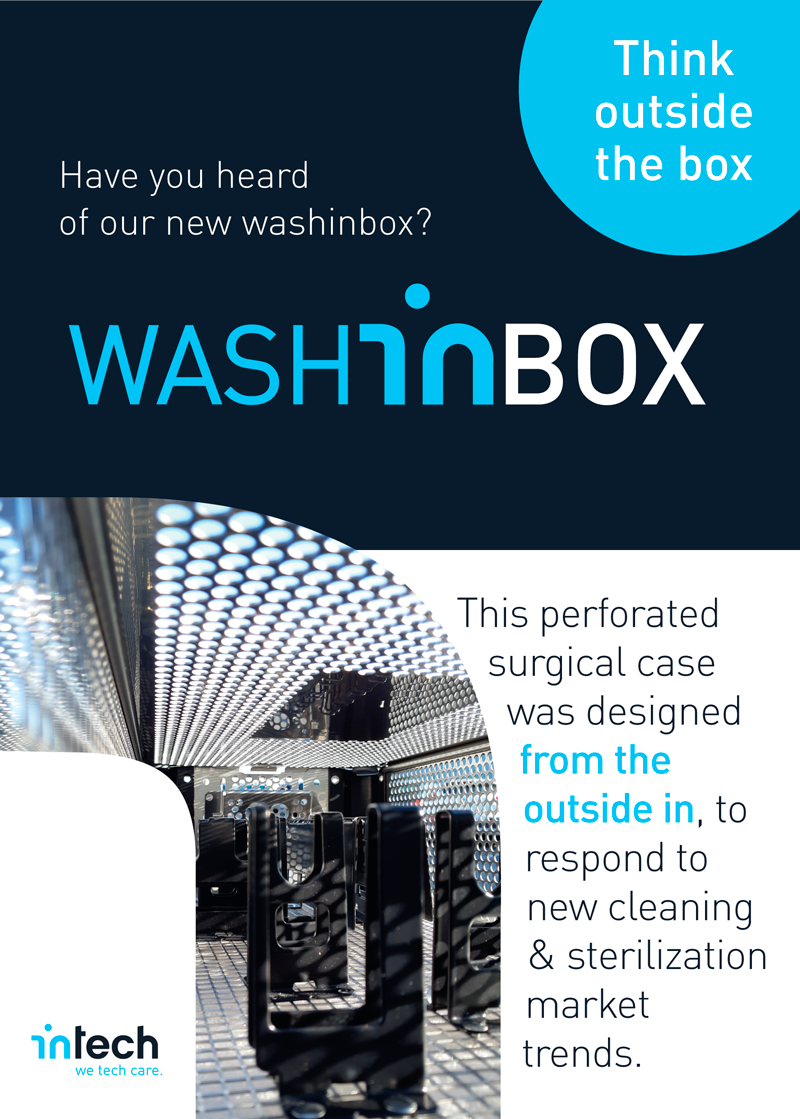

Thinking outside the box

Creativity is our tool! Our bold designs combine ergonomics, resistance and modularity to produce customized cases perfectly designed to organize your surgical kit.

Cases & Trays

Thinking outside the box

Creativity is our tool! Our bold designs combine ergonomics, resistance and modularity to produce customized cases perfectly designed to organize your surgical kit.

Precision like no other

Our unique expertise in machining of complex components as well as our advanced industrial technology ensure we hold tight tolerances required for laser-focused computer assisted surgeries.

Pioneers driven by innovation, we fully embrace new surgical techniques and empower them with our unique manufacturing know-how.

Robotics & Navigation

Precision like no other

Our unique expertise in machining of complex components as well as our advanced industrial technology ensure we hold tight tolerances required for laser-focused computer assisted surgeries.

Pioneers driven by innovation, we fully embrace new surgical techniques and empower them with our unique manufacturing know-how.

Finishing on a high note with best-in-class QA & vertically integrated post-procesing solutions :

- Titanium Type II & III anodizing

- Chrome Coating

- Laser Marking (2D datamatrix)

- Passivation

- Cleaning

- Packaging

Special Processes & Services

Finishing on a high note with best-in-class QA & vertically integrated post-procesing solutions :

- Titanium Type II & III anodizing

- Chrome Coating

- Laser Marking (2D datamatrix)

- Passivation

- Cleaning

- Packaging

Sharp as a tack!

With recent acquisition of Lenkbar in 2023, Intech adds vertically-integrated capabilities that span from gun-drilling to grinding of drills, taps and handheld devices.

The 31,000 sq.ft facility in Naples, FL. enhances the group’s offering with state-of-the-art infrastructure and cutting-edge technology that allows end-to-end turning and grinding of single-use devices, the way to cleaning, passivation, and sterile packaging.

Cutting Tools

Sharp as a tack!

With recent acquisition of Lenkbar in 2023, Intech adds vertically-integrated capabilities that span from gun-drilling to grinding of drills, taps and handheld devices.

The 31,000 sq.ft facility in Naples, FL. enhances the group’s offering with state-of-the-art infrastructure and cutting-edge technology that allows end-to-end turning and grinding of single-use devices, the way to cleaning, passivation, and sterile packaging.

The strongest flexible shaft on the market

Lenkbar’s signature FlexMetric® can be adapted to most surgical devices for precision surgery in tight spaces. It is a patented cannulated, flexible shaft that enables surgical drilling, reaming, pushing and punching around corners and hard to reach areas.

It maintains access and control while creating a true non-wobble arc.

Flexible Shafts

The strongest flexible shaft on the market

Lenkbar’s signature FlexMetric® can be adapted to most surgical devices for precision surgery in tight spaces. It is a patented cannulated, flexible shaft that enables surgical drilling, reaming, pushing and punching around corners and hard to reach areas.

It maintains access and control while creating a true non-wobble arc.

Market-ready systems, built for speed.

As a Manufacturer of Record (510(k) – EUMDR etc.), we deliver turnkey, regulatory-ready systems designed to accelerate time-to-market and support scalable global market introduction. Our fully integrated in-house capabilities span from concept design, clinical evaluation, precision manufacturing, kitting, and sterile packaging. This ensures streamlined execution and end-to-end quality control. Whether you’re developing a new device or expanding into new markets, we offer the infrastructure and expertise to bring complete, market-ready systems to life. Faster and at global scale.

Turnkey Systems

Market-ready systems, built for speed.

As a Manufacturer of Record (510(k) – EUMDR etc.), we deliver turnkey, regulatory-ready systems designed to accelerate time-to-market and support scalable global market introduction. Our fully integrated in-house capabilities span from concept design, clinical evaluation, precision manufacturing, kitting, and sterile packaging. This ensures streamlined execution and end-to-end quality control. Whether you’re developing a new device or expanding into new markets, we offer the infrastructure and expertise to bring complete, market-ready systems to life. Faster and at global scale.

Stronger Fixation Starts Here

In-house expertise in braided cables, crimping tools, and locking mechanisms built for reliability and scalability.

Our portfolio includes:

- Cables ranging from 1.0mm to 2.0mm, manufactured in Stainless Steel, Titanium, Cobalt Chrome, and Titanium Aluminium Nitrate

- Custom braided cable options developed for specialized clinical needs

- A variety of locking mechanisms, both stand-alone and plate-integrated

- Torque driver and crimping system designs, tailored to match every implant configuration

- Fully supported regulatory pathway development and testing for global market introduction

Complete Cerclage Systems

Stronger Fixation Starts Here

In-house expertise in braided cables, crimping tools, and locking mechanisms built for reliability and scalability.

Our portfolio includes:

- Cables ranging from 1.0mm to 2.0mm, manufactured in Stainless Steel, Titanium, Cobalt Chrome, and Titanium Aluminium Nitrate

- Custom braided cable options developed for specialized clinical needs

- A variety of locking mechanisms, both stand-alone and plate-integrated

- Torque driver and crimping system designs, tailored to match every implant configuration

- Fully supported regulatory pathway development and testing for global market introduction

130 Durham Drive

Athens, AL 35611

United States

10325 58th Place

Kenosha, WI 53144

United States

2705 Corporate Flight Dr

Naples, FL 34104

United States

300 Roundhill DriveSuite # 6

Rockaway, NJ 07866

United States

2821 Tingkat Perusahaan 5A

13600 Prai Penang, Penang (Pulau Pinang) 13600

Malaysia

93-95 avenue du Champ Gretz

Rang-du-Fliers 62180

France

1 Rue Nungesser et Coli

Châtellerault 86100

France

9, Route de Marcilly

Saint-Soupplets 77165

France

120 Rue Pasteur

La Farlède 83210

France

375 River Park Circle

Marquette, MI 49855

United States

12702 Trade Way Dr #3

Bonita Springs, FL 34135

United States

89 S Commerce Way

Bethlehem, PA 18017

United States