-

Huron Tool and Cutter Grinding Co Inc

485 Smith Street

Farmingdale, NY

11735

United States - 40,000 sq. ft.

- 631-420-7000

- 70+ employees

- Founded in 1956

- Operating in North America

- Visit Website

President

Changes saved

- Component Parts

- Instruments

- Manufacturing

- Product Development

- Surface Preparation/Treatments

With nearly 70 years in precision manufacturing, Huron Tool & Cutter Grinding specializes in orthopedic instruments and cutting tools. Our end-to-end production solution leverages in-house capabilities—Swiss turning, gun drilling, cutter grinding, laser welding, and assembly—enabling precise control and reduced outsourcing. Additionally, we collaborate with customers in the design phase to enhance manufacturability and refine processes, making us a trusted partner in the medical device industry.

- Cannulated or Solid Drills, Taps & Reamers

- Bone Screws

- Handled Instruments

- Multiple Component Assemblies

- External Fixation Pins

- Intramedullary Reamers

- Long Reamers, Coring Reamers

Product Expertise

- Cannulated or Solid Drills, Taps & Reamers

- Bone Screws

- Handled Instruments

- Multiple Component Assemblies

- External Fixation Pins

- Intramedullary Reamers

- Long Reamers, Coring Reamers

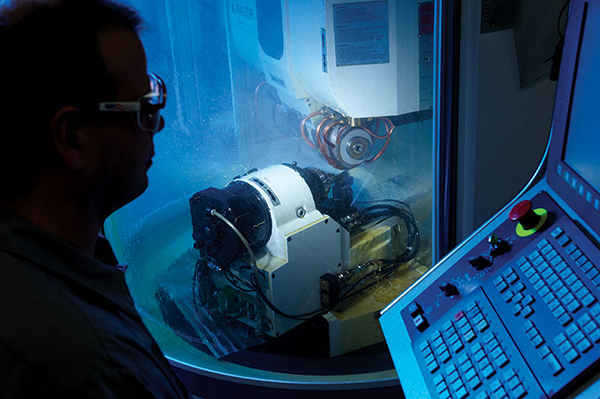

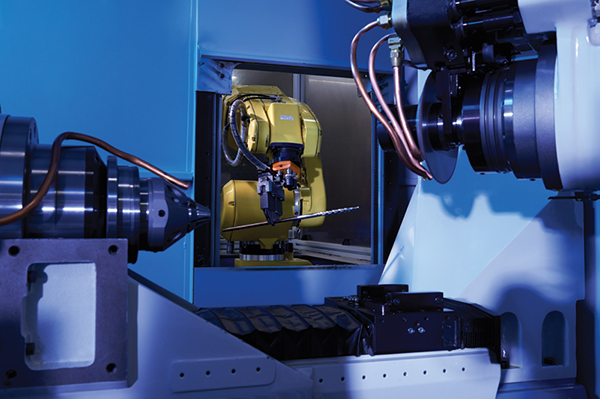

Huron is equipped with the industry’s latest and most trusted CAD/CAM and CAD/KEY software tools to ensure precision and repeatability. These include SolidWorks®, AutoCAD®, and PartMaker®. Services include robotic and automated CNC production of stainless, aluminum and titanium. Huron’s team of highly skilled machinists are made up of experts in CNC turning, milling & machining services, emphasizing high-speed production and robotic machining.

Robotic CNC Machining

Huron is equipped with the industry’s latest and most trusted CAD/CAM and CAD/KEY software tools to ensure precision and repeatability. These include SolidWorks®, AutoCAD®, and PartMaker®. Services include robotic and automated CNC production of stainless, aluminum and titanium. Huron’s team of highly skilled machinists are made up of experts in CNC turning, milling & machining services, emphasizing high-speed production and robotic machining.

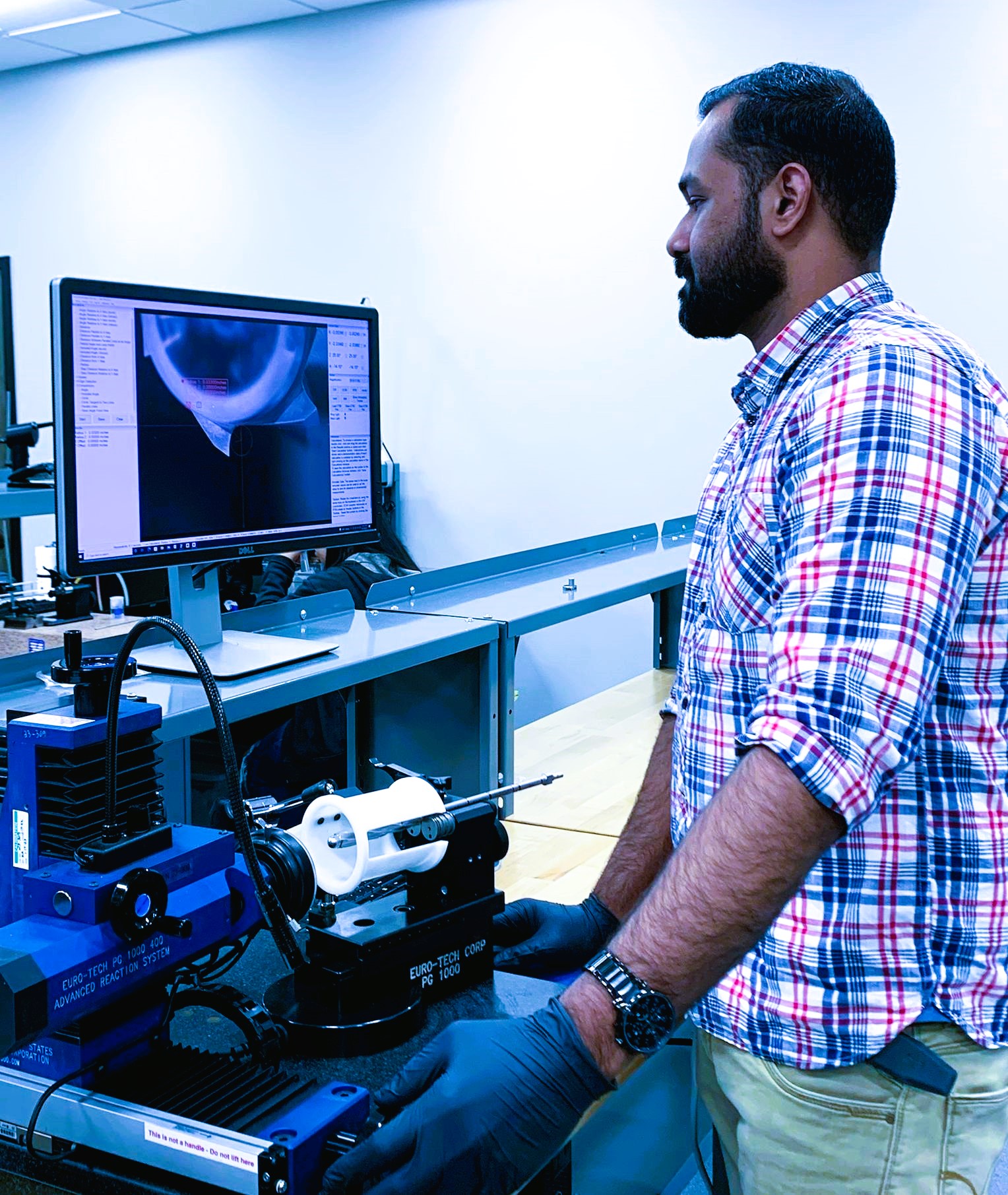

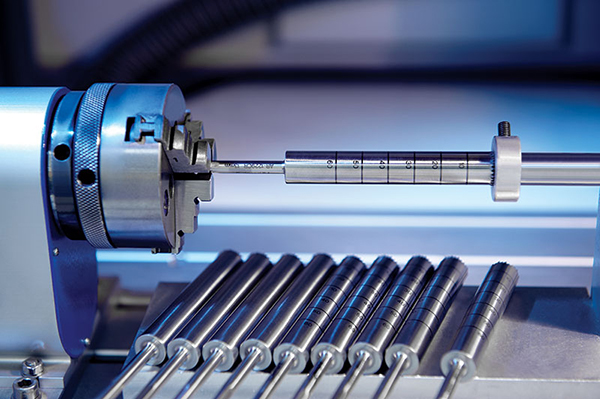

Gun Drilling Huron specializes in drilling straight, deep, accurate, close tolerance holes, from .032″ to .750″ and to a depth of 36″. Capabilities include drilling concentric or off-center holes, in most materials, including alloy steels, tool steels, stainless steels and other non-ferrous metals. Achieve some of the highest diameter to depth ratios possible.

Gun Drilling

Gun Drilling Huron specializes in drilling straight, deep, accurate, close tolerance holes, from .032″ to .750″ and to a depth of 36″. Capabilities include drilling concentric or off-center holes, in most materials, including alloy steels, tool steels, stainless steels and other non-ferrous metals. Achieve some of the highest diameter to depth ratios possible.

Heat Treating

Huron metallurgic heat treating services include controlled atmosphere processing for your hardness requirements.

Electropolishing

Electrochemical in nature, the electropolishing process uses a combination of rectified current and a blended chemical electrolyte bath to remove flaws from the surface of a metal part.

Passivation

Passivation is a chemical process that removes free iron and creates a chromium-rich surface on the material. This process improves corrosion resistance on a wide range of metals, including the full range of stainless steels and many other alloys.

Heat Treating, Electropolishing & Passivation

Heat Treating

Huron metallurgic heat treating services include controlled atmosphere processing for your hardness requirements.

Electropolishing

Electrochemical in nature, the electropolishing process uses a combination of rectified current and a blended chemical electrolyte bath to remove flaws from the surface of a metal part.

Passivation

Passivation is a chemical process that removes free iron and creates a chromium-rich surface on the material. This process improves corrosion resistance on a wide range of metals, including the full range of stainless steels and many other alloys.

Huron Wire EDM capabilities include the cutting of most metals to tolerances within +/- .0002”. The wire diameter used for cutting is.010”, achieving accurate tapers of up to 30°. This level of cutting precision translates into the ability to produce highly complex parts, designed with the most challenging dimensions.

Wire EDM

Huron Wire EDM capabilities include the cutting of most metals to tolerances within +/- .0002”. The wire diameter used for cutting is.010”, achieving accurate tapers of up to 30°. This level of cutting precision translates into the ability to produce highly complex parts, designed with the most challenging dimensions.

Huron provides PVD Coating featuring Titanium Nitride (TiN) and Chromium Nitride (CrN) to a variety of materials. The most common of the PVD coatings, Titanium Nitride is an extremely hard, inert, thin-film coating that is applied primarily to precision metal parts, adding hardness and durability to the parts being treated.

Titanium Nitride & Chromium Nitride Coating

Huron provides PVD Coating featuring Titanium Nitride (TiN) and Chromium Nitride (CrN) to a variety of materials. The most common of the PVD coatings, Titanium Nitride is an extremely hard, inert, thin-film coating that is applied primarily to precision metal parts, adding hardness and durability to the parts being treated.

Huron has provided high-contrast, permanent marking and engraving services for manufacturers of surgical tools, implants and instruments for more than 20 years. Laser marking is used so that low-impact surface marks can give traceability to components without creating hygiene traps.

Laser Marking & Engraving

Huron has provided high-contrast, permanent marking and engraving services for manufacturers of surgical tools, implants and instruments for more than 20 years. Laser marking is used so that low-impact surface marks can give traceability to components without creating hygiene traps.

Epoxy resin in your choice of color. Helps keep instruments organized. Easily identified by surgeons and staff.

Color Coded Instruments

Epoxy resin in your choice of color. Helps keep instruments organized. Easily identified by surgeons and staff.

New Product Development and Prototyping at Huron are considered some of the most important services the company provides. Over the years, Huron has partnered with its customers not only to develop brand new and groundbreaking innovations that have helped advance what orthopedists can achieve every day in the surgical suite, but it has also taken basic surgical tools and improved on their design to enhance their performance on patients.

New Product Development & Prototyping

New Product Development and Prototyping at Huron are considered some of the most important services the company provides. Over the years, Huron has partnered with its customers not only to develop brand new and groundbreaking innovations that have helped advance what orthopedists can achieve every day in the surgical suite, but it has also taken basic surgical tools and improved on their design to enhance their performance on patients.

Farmingdale, NY 11735

United States