-

Himed

148 Bethpage-Sweet Hollow Rd

Old Bethpage, NY

11804

United States - 25,000 square feet

- 516-586-5700

- 36+ employees

- Founded in 1991

- Operating in North America

- Visit Website

Chief Executive Officer

President

Changes saved

- Additive Manufacturing

- Materials/Bio and Performance

- Product Development

- Surface Preparation/Treatments

- Testing

For over 30 years, Himed has provided innovative biomaterial solutions to orthopedic and dental customers around the world. Beginning in 1991 with early innovations in hydroxyapatite coatings and abrasives, Himed became a leader in biomaterial production through novel processes for highly customizable bioactive plasma spray coatings and other surface treatments. Himed is also a contract R&D and production partner, supporting clients as they develop new processes, products, and applications.

Innovative methods for crafting high quality bioactive powders

Most Himed biomaterials are available as powders, available in conventional or irregular shapes and variable porosity. While we offer calcium phosphate powders in a variety of standard compositions, we can also customize our powders to the specific application methodology and intended outcomes indicated by our clients.

- Bioactive coating powders

- Regular and irregular granules

- Resorbable blast media (RBM)

- Customized powder manufacturing

Powders

Innovative methods for crafting high quality bioactive powders

Most Himed biomaterials are available as powders, available in conventional or irregular shapes and variable porosity. While we offer calcium phosphate powders in a variety of standard compositions, we can also customize our powders to the specific application methodology and intended outcomes indicated by our clients.

- Bioactive coating powders

- Regular and irregular granules

- Resorbable blast media (RBM)

- Customized powder manufacturing

Customizable forms for health products, evaluation, & research

Himed can cast calcium phosphates into virtually any shape. These forms have great strength too. They are available in HA, beta-TCP, and various BCP mixtures. Our cast forms can be used for evaluation of oral care products, and to simulate teeth or bone in experiments in industrial or educational laboratories. Our forms include:

- Gel cast bone-like shapes

- Hydroxyapatite whiskers

- Calcium phosphate discs & slides

- CaP/polymer composites

Forms

Customizable forms for health products, evaluation, & research

Himed can cast calcium phosphates into virtually any shape. These forms have great strength too. They are available in HA, beta-TCP, and various BCP mixtures. Our cast forms can be used for evaluation of oral care products, and to simulate teeth or bone in experiments in industrial or educational laboratories. Our forms include:

- Gel cast bone-like shapes

- Hydroxyapatite whiskers

- Calcium phosphate discs & slides

- CaP/polymer composites

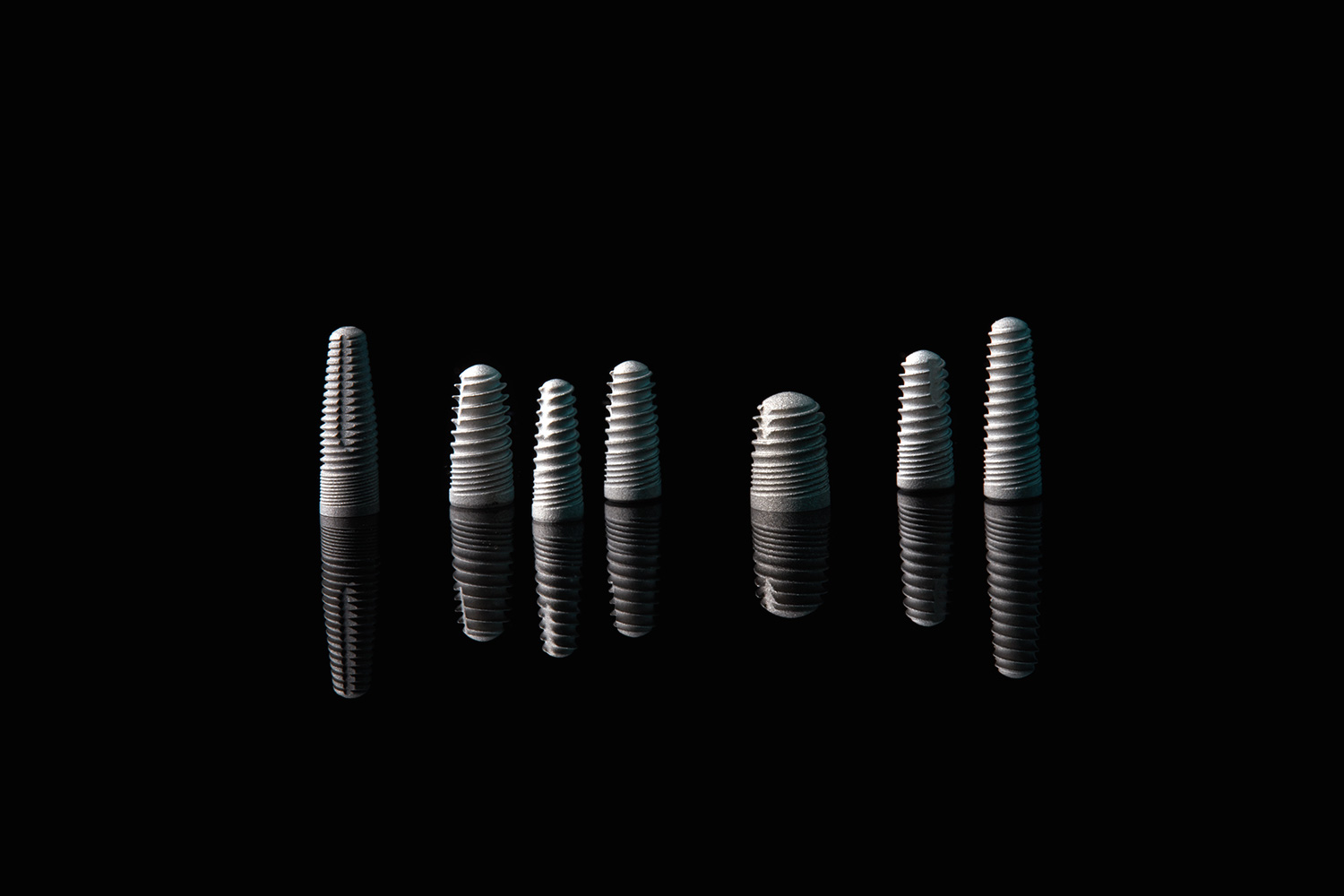

A better osteoconductive coating solution for medical implants

Himed’s MATRIX HA® uses an atmospheric plasma spray system to apply a dense coating of our hydroxyapatite on virtually residue-free MCD grit-blasted dental implants and medical devices. The process is performed robotically to precisely control the spray pattern, thereby guaranteeing consistent and reproducible coatings on small or high-volume lots.

Surface Treatment - MATRIX HA®

A better osteoconductive coating solution for medical implants

Himed’s MATRIX HA® uses an atmospheric plasma spray system to apply a dense coating of our hydroxyapatite on virtually residue-free MCD grit-blasted dental implants and medical devices. The process is performed robotically to precisely control the spray pattern, thereby guaranteeing consistent and reproducible coatings on small or high-volume lots.

Exacting micro-abrasive grit blasting with biocompatible material

Grit-blasting with Himed’s MCD RBM creates a virtually residue-free textured surface, critical for increasing the surface area for osseointegration, or as a preparation prior to the other coatings like hydroxyapatite or titanium. Conventional blasting techniques utilizing alumina or silicon carbide leave residual abrasive as a contaminant; Himed’s MATRIX MCD® eliminates these contaminants, resulting in a cleaner textured surface.

Surface Treatment - MATRIX MCD®

Exacting micro-abrasive grit blasting with biocompatible material

Grit-blasting with Himed’s MCD RBM creates a virtually residue-free textured surface, critical for increasing the surface area for osseointegration, or as a preparation prior to the other coatings like hydroxyapatite or titanium. Conventional blasting techniques utilizing alumina or silicon carbide leave residual abrasive as a contaminant; Himed’s MATRIX MCD® eliminates these contaminants, resulting in a cleaner textured surface.

Innovative process for an enhanced surface morphology

Himed’s MATRIX Dual® system allows for profoundly nuanced surface texturing using our proprietary MCD Apatitic Abrasive. Multiple blast cycles of our resorbable medium form a complex, even network of micro and macro pits. The resulting surface morphology provides a matrix for bone cells, optimizing conditions for orthopedic or dental implant integration. Dual is ideal for clients requiring uniquely precise reproducible surface characteristics.

Surface Treatment - MATRIX Dual®

Innovative process for an enhanced surface morphology

Himed’s MATRIX Dual® system allows for profoundly nuanced surface texturing using our proprietary MCD Apatitic Abrasive. Multiple blast cycles of our resorbable medium form a complex, even network of micro and macro pits. The resulting surface morphology provides a matrix for bone cells, optimizing conditions for orthopedic or dental implant integration. Dual is ideal for clients requiring uniquely precise reproducible surface characteristics.

Titanium coatings consistently applied at competitive costs

Himed’s MATRIX Ti® is a patented process that produces titanium-rich porous coatings with a highly textured surface ideally suited to encourage osseointegration. Unlike conventional vacuum sprayed coatings, our air plasma spray system is performed by six axes of robotic motion, controlling the spray pattern to guarantee consistent and reproducible results.

Surface Treatment - MATRIX Ti®

Titanium coatings consistently applied at competitive costs

Himed’s MATRIX Ti® is a patented process that produces titanium-rich porous coatings with a highly textured surface ideally suited to encourage osseointegration. Unlike conventional vacuum sprayed coatings, our air plasma spray system is performed by six axes of robotic motion, controlling the spray pattern to guarantee consistent and reproducible results.

A biocompatible Type III color anodizing solution

Himed’s MATRIX Color® is a fully automated Type III color titanium anodizing system offering a complete range of colors for all alloyed and CP titanium orthopedic, dental and spinal implants, instruments, fasteners and screws. This vibrant sanitary surface simplifies the identification of parts and provides an aesthetically unique finish. MATRIX Color® is customizable and can be used in conjunction with other MATRIX® surface treatments.

Surface Treatment - MATRIX Color®

A biocompatible Type III color anodizing solution

Himed’s MATRIX Color® is a fully automated Type III color titanium anodizing system offering a complete range of colors for all alloyed and CP titanium orthopedic, dental and spinal implants, instruments, fasteners and screws. This vibrant sanitary surface simplifies the identification of parts and provides an aesthetically unique finish. MATRIX Color® is customizable and can be used in conjunction with other MATRIX® surface treatments.

Rapid additive prototyping with bioceramics

The era of implantable medical devices leveraging the regenerative potentials of bioceramic materials is upon us. Enabled by the manufacturing precision of 3D-printing, and ongoing developments in printable bioinks, a new frontier of highly customizable, print-on-demand, orthopedic and dental devices promises to dramatically improve patient outcomes.

To accelerate these developments, Himed and Lithoz—two companies renowned in their respective sectors for vanguard thinking—have joined forces to deliver a contract research experience that will enable companies of all sizes to test their device design concepts, and refine them in a workflow conceived to scale gracefully into production.

Ready to design the future? We’re here to help.

Biomaterials Center of Excellence

Rapid additive prototyping with bioceramics

The era of implantable medical devices leveraging the regenerative potentials of bioceramic materials is upon us. Enabled by the manufacturing precision of 3D-printing, and ongoing developments in printable bioinks, a new frontier of highly customizable, print-on-demand, orthopedic and dental devices promises to dramatically improve patient outcomes.

To accelerate these developments, Himed and Lithoz—two companies renowned in their respective sectors for vanguard thinking—have joined forces to deliver a contract research experience that will enable companies of all sizes to test their device design concepts, and refine them in a workflow conceived to scale gracefully into production.

Ready to design the future? We’re here to help.

Your partner in biomaterial analysis & innovation

With three on-site labs in our 25,000 sq. ft. facility, Himed can provide contract biomaterial research for our clients. If you’re looking for an R&D contractor with the right blend of problem solving, engineering strength, and analytical rigor then let Himed’s 30+ years of experience support you in the creation of your next product.

We provide the following analytical services:

- Scanning electron microscopy (SEM)

- Energy-dispersive X-ray spectroscopy (EDS/EDX)

- X-Ray powder diffraction (XRD)

- ICP elemental analysis

- FTIR spectrospcopy services

- Particle size & moisture analysis

- Tensile/shear mechanical testing

- Taber abrasion testing

- Skeletal density/gas pycnometry

Himed is ISO 13485:2016 certified and FDA registered.

Analytical Lab Services

Your partner in biomaterial analysis & innovation

With three on-site labs in our 25,000 sq. ft. facility, Himed can provide contract biomaterial research for our clients. If you’re looking for an R&D contractor with the right blend of problem solving, engineering strength, and analytical rigor then let Himed’s 30+ years of experience support you in the creation of your next product.

We provide the following analytical services:

- Scanning electron microscopy (SEM)

- Energy-dispersive X-ray spectroscopy (EDS/EDX)

- X-Ray powder diffraction (XRD)

- ICP elemental analysis

- FTIR spectrospcopy services

- Particle size & moisture analysis

- Tensile/shear mechanical testing

- Taber abrasion testing

- Skeletal density/gas pycnometry

Himed is ISO 13485:2016 certified and FDA registered.

Find us on social media:

Request our catalog:

Request our white papers:

Connect with Us

Find us on social media:

Request our catalog:

Request our white papers:

Old Bethpage 11804

United States