-

Hammill Medical

360 Tomahawk Dr

Maumee, OH

43537

United States - 90,000 sq. ft.

- 419-476-0789

- 200+ employees

- Founded in 1955

- Operating in North America

- Visit Website

President

Changes saved

- Additive Manufacturing

- Equipment/Machinery

- Instruments

- Logistics/Supply Chain

- Manufacturing

- Packaging

- Product Development

- Regulatory/Quality Assurance

- Surface Preparation/Treatments

- Testing

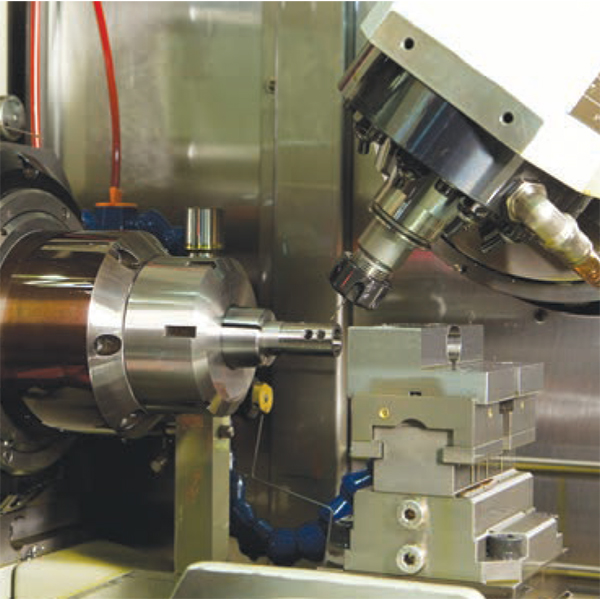

Precision Manufacturer of Medical Implants and Surgical Instruments. Our capabilities include CNC grinding, 5-axis machining centers, CNC turning and mill/turn centers, Multi-Axis Swiss style turning, robotic polishing, laser part identification, CNC thread milling, ultrasonic cleaning and passivation, sterile, label and pack. 3D solid modeling for design and for integrated part programming. FDA Registered #1530390; ISO 13485:2003.

We continuously invest in high-precision, high-technology equipment including multi-axis CNC grinding, 5-axis machining centers, CNC turning and mill/turn centers, laser welding and color titanium anodizing, up to 11-Axis Swiss style turning, robotic polishing, laser part identification, CNC thread milling, ultrasonic cleaning and passivation, a state of the art inspection lab, sterilization, labeling, and packaging. In addition, we utilize 3D solid modeling for design and for integrated part programming.

Manufacturing and Design

We continuously invest in high-precision, high-technology equipment including multi-axis CNC grinding, 5-axis machining centers, CNC turning and mill/turn centers, laser welding and color titanium anodizing, up to 11-Axis Swiss style turning, robotic polishing, laser part identification, CNC thread milling, ultrasonic cleaning and passivation, a state of the art inspection lab, sterilization, labeling, and packaging. In addition, we utilize 3D solid modeling for design and for integrated part programming.

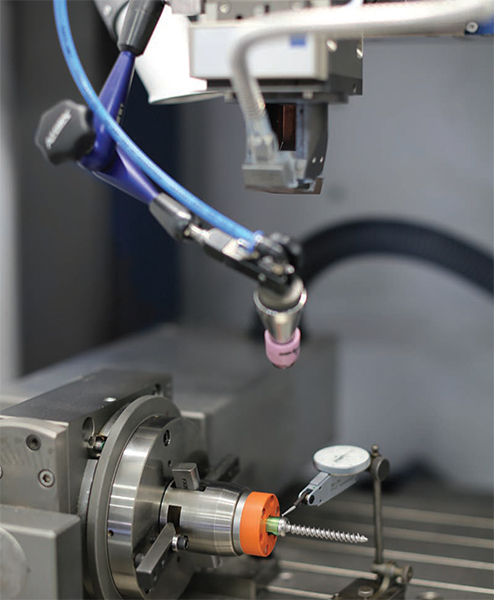

Our engineering staff works with our customers’ design engineers to provide value-added products and product enhancements. Throughout the implant design, development, prototyping and testing stages, we work in concert with our customers to develop optimal implant design and to engineer cost-effective, statistically capable manufacturing processes and inspection processes.

Engineering and Product Design

Our engineering staff works with our customers’ design engineers to provide value-added products and product enhancements. Throughout the implant design, development, prototyping and testing stages, we work in concert with our customers to develop optimal implant design and to engineer cost-effective, statistically capable manufacturing processes and inspection processes.

Our commitment to innovation, precision and integrity results in the highest quality products in the medical implant industry with exceptional response time. Our customers are among the finest and most respected companies in the world. We do not settle for anything less than the highest quality and integrity in everything we do. Our customers would not accept anything less!

Commitment to Quality

Our commitment to innovation, precision and integrity results in the highest quality products in the medical implant industry with exceptional response time. Our customers are among the finest and most respected companies in the world. We do not settle for anything less than the highest quality and integrity in everything we do. Our customers would not accept anything less!

• Knee Femoral Components:

– Cruciate Retaining (CR)

– Posterior Stabilizing (PS)

– Revision (REV) Stems

– Trials (CR, PS and REV)

• Trauma Hip Systems

• Modular Hip Systems

• Spinal Systems

• Bone Screws

• Surgical Instruments

• PEEK Machining

Products

• Knee Femoral Components:

– Cruciate Retaining (CR)

– Posterior Stabilizing (PS)

– Revision (REV) Stems

– Trials (CR, PS and REV)

• Trauma Hip Systems

• Modular Hip Systems

• Spinal Systems

• Bone Screws

• Surgical Instruments

• PEEK Machining

Maumee, OH

United States