-

DOT America Inc

335 S Towerview Dr

Columbia City, IN

46725

United States - 17,500 sq. ft. - over 7 acres

- 260-244-5700

- 37+ employees

- Founded in 2013

- Operating in North America

- Visit Website

President, CEO

VP Business Development & Engineering

Changes saved

- Equipment/Machinery

- Instruments

- Manufacturing

- Packaging

- Surface Preparation/Treatments

DOT offers a wide range of surface treatments for orthopaedic and dental implants as well as instruments and cleanroom packaging, such as PVD coatings (TiN, TiNbN, ZrN, CrN, DLC and TiAlN); TPS coatings on metal, PEEK and ceramics; Electro-chemical CaP deposition (BONIT® coating), Sprayed HA coatings, Anodic oxidation types II (DOTIZE®) and III (color) and antimicrobial coatings. This facility, located in Columbia City, IN, is an extension to DOT GmbH located in Rostock, Germany.

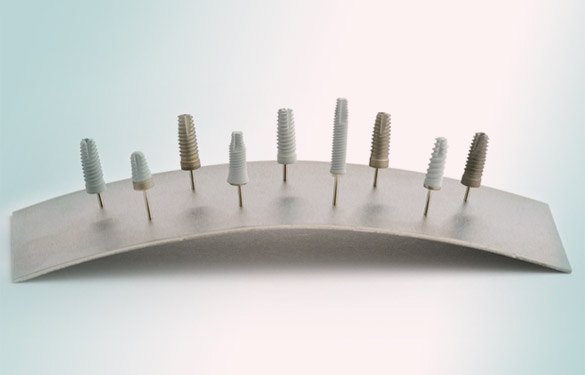

Implant Coatings PVD coatings (TiN, TiNbN, TiAlN, …)

Ultra-hard ceramic coatings for implantable devices and orthopedic/dental instrumentation

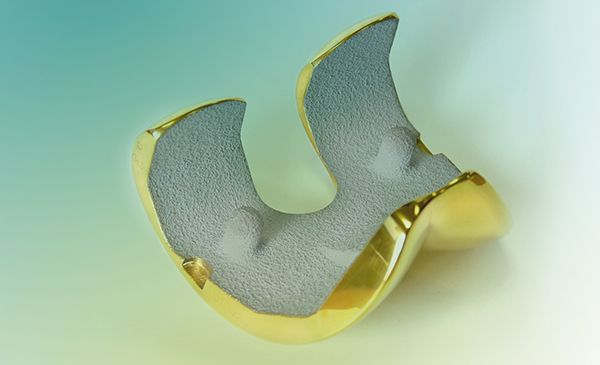

Titanium plasma spray (TPS)

Firm fixation by using porous plasma-sprayed titanium coatings for orthopedic implants

Plasma-sprayed HA

Plasma-sprayed HA coatings for orthopedic applications

Bone On-growth Surfaces (RBM, Micro-blast and Etch)

Micron scale surface technologies for titanium-based spinal screws, dental implants and other bone engaging implants

Type II Anodizing (DOTIZE®)

Enhanced oxide coating for titanium-based trauma and spine fixation devices intended for temporary implantation

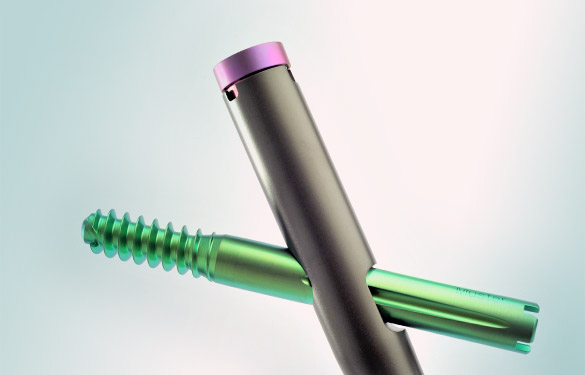

Type III Color Anodizing

Precise modification of the naturally occurring titanium oxide layer to create thin film interference coloration of devices

Implant Coatings

Implant Coatings PVD coatings (TiN, TiNbN, TiAlN, …)

Ultra-hard ceramic coatings for implantable devices and orthopedic/dental instrumentation

Titanium plasma spray (TPS)

Firm fixation by using porous plasma-sprayed titanium coatings for orthopedic implants

Plasma-sprayed HA

Plasma-sprayed HA coatings for orthopedic applications

Bone On-growth Surfaces (RBM, Micro-blast and Etch)

Micron scale surface technologies for titanium-based spinal screws, dental implants and other bone engaging implants

Type II Anodizing (DOTIZE®)

Enhanced oxide coating for titanium-based trauma and spine fixation devices intended for temporary implantation

Type III Color Anodizing

Precise modification of the naturally occurring titanium oxide layer to create thin film interference coloration of devices

The quality of coatings depends on the initial state of the surface.

That is why we offer our customers the option of surface preparation by

polishing, blasting and passivation. Precision marking, engraving or ablation

for implantable devices and orthopedic/dental instrumentation.

Surface Treatments

The quality of coatings depends on the initial state of the surface.

That is why we offer our customers the option of surface preparation by

polishing, blasting and passivation. Precision marking, engraving or ablation

for implantable devices and orthopedic/dental instrumentation.

Columbia City, IN

United States