-

Cadence, Inc.

9 Technology Dr.

Staunton, VA

24401

United States - 457,500+ sq. ft., Facilities: 8

- 540-248-2200

- 800+ employees

- Founded in 1985

- Operating in Europe, Global, North America

- Visit Website

Changes saved

- Additive Manufacturing

- Instruments

- Manufacturing

- Materials/Metals

- Packaging

- Product Development

- Surface Preparation/Treatments

- Testing

Cadence is the orthopedic supplier of choice for advanced products used in the orthopedic market. We act as a trusted CDMO partner in developing, manufacturing, and assembling numerous complex products in the areas of spine, trauma, joint replacement and sports medicine. Cadence employs approximately 800 people with its corporate headquarters in Staunton, Virginia and additional locations in Connecticut, Pennsylvania, Rhode Island, Wisconsin, Florida, and Costa Rica.

Cadence collaborates with our customers to solve complex challenges through the entire development process including DFM and DFA. For early-stage products, we have the experience to produce support throughout the different phases of clinical trials as they are an essential part of developing and bringing new products safely to market.

Our Product/Process Development Services Include:

- Product Design Concept

- Design Feasibility

- Design for Manufacturing

- World-class Program Management

- Regulatory & Clinical

- Process Validation

- Manufacturing Transfer

- Product Lifecycle Management

Our expert team, combined with our various services, capabilities, and outstanding customer support, ensure our OEM partners’ product success.

Product/Process Development

Cadence collaborates with our customers to solve complex challenges through the entire development process including DFM and DFA. For early-stage products, we have the experience to produce support throughout the different phases of clinical trials as they are an essential part of developing and bringing new products safely to market.

Our Product/Process Development Services Include:

- Product Design Concept

- Design Feasibility

- Design for Manufacturing

- World-class Program Management

- Regulatory & Clinical

- Process Validation

- Manufacturing Transfer

- Product Lifecycle Management

Our expert team, combined with our various services, capabilities, and outstanding customer support, ensure our OEM partners’ product success.

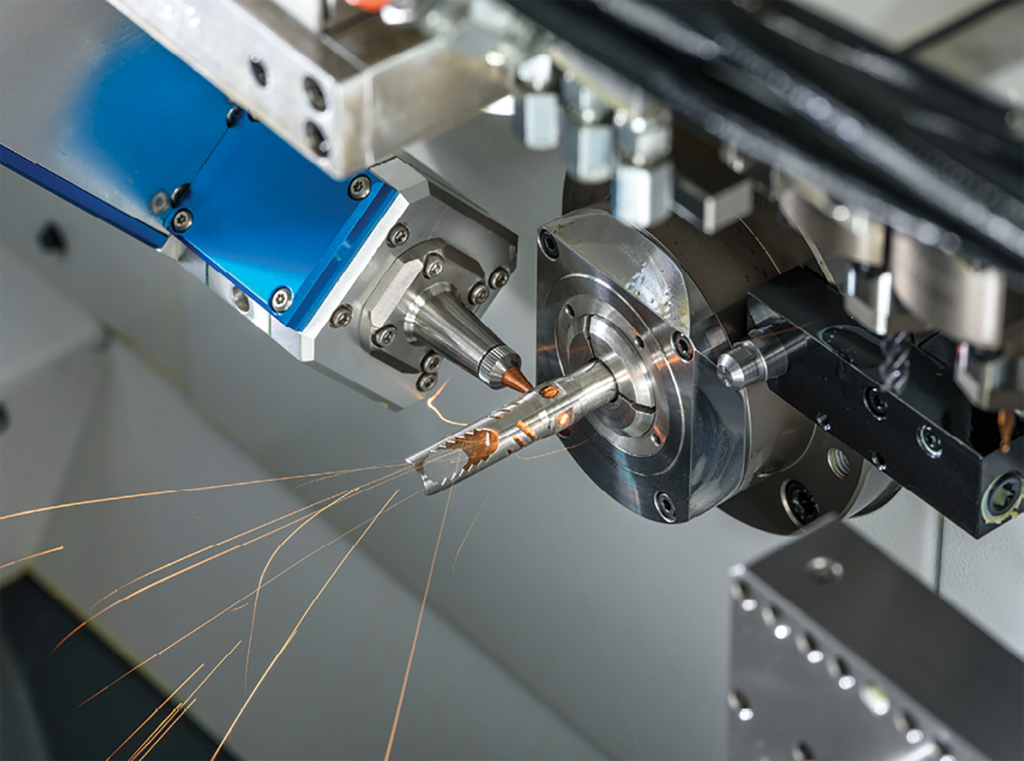

- Sharps – Specialty Blades and Needles

- Machining – Swiss, CNC, Micro, and LaserSwiss

- Laser Cutting, Welding, Drilling, and Marking

- Multi-slide Forming and Microstamping

- Metal Injection Molding (MIM)

- Precision Metal Stamping

- Deep Draw Technologies

- Tube Fabrication

- EDM – Wire, Ram and Sink

- Nitinol Shape Setting

- Advanced Welding Lab™

- IncisionLab™

Metals Expertise

- Sharps – Specialty Blades and Needles

- Machining – Swiss, CNC, Micro, and LaserSwiss

- Laser Cutting, Welding, Drilling, and Marking

- Multi-slide Forming and Microstamping

- Metal Injection Molding (MIM)

- Precision Metal Stamping

- Deep Draw Technologies

- Tube Fabrication

- EDM – Wire, Ram and Sink

- Nitinol Shape Setting

- Advanced Welding Lab™

- IncisionLab™

- 3D Printing

- PEEK Machining

- Insert Molding

- Overmolding

- Cleanroom Molding

- Engineered Resins Expertise

- Sharps Molding & Handling

- Reel-to-Reel Molding

Plastics Expertise

- 3D Printing

- PEEK Machining

- Insert Molding

- Overmolding

- Cleanroom Molding

- Engineered Resins Expertise

- Sharps Molding & Handling

- Reel-to-Reel Molding

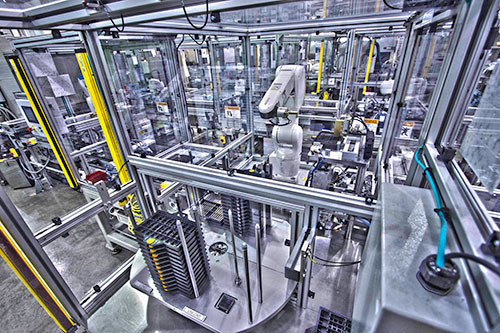

Cadence assembles Class I and Class II registered devices for some of the most demanding customers in the MedTech and Pharma markets in our eGMP facilities, including dedicated device facilities in Cranberry Township, PA, and Alajuela, Costa Rica.

Cadence prides itself on a strong track record of regulatory compliance. All of our facilities are ISO 13485 certified and registered with the FDA where applicable. Our robust Quality Management System (QMS) ensures compliance to all regulatory requirements and standards.

We provide the following finished device capabilities:

- Cleanroom Manufacturing (Class 7 and Class 8)

- Final Assembly

- Testing and Inspection Services

- Final Packaging and Labeling

- Sterilization Management

- Supply Chain Management

Finished Medical Devices

Cadence assembles Class I and Class II registered devices for some of the most demanding customers in the MedTech and Pharma markets in our eGMP facilities, including dedicated device facilities in Cranberry Township, PA, and Alajuela, Costa Rica.

Cadence prides itself on a strong track record of regulatory compliance. All of our facilities are ISO 13485 certified and registered with the FDA where applicable. Our robust Quality Management System (QMS) ensures compliance to all regulatory requirements and standards.

We provide the following finished device capabilities:

- Cleanroom Manufacturing (Class 7 and Class 8)

- Final Assembly

- Testing and Inspection Services

- Final Packaging and Labeling

- Sterilization Management

- Supply Chain Management

Staunton 24401

Afghanistan

Cranston 02921

Afghanistan

Suite 400

Cranberry Township 16066

Afghanistan

Sturgeon Bay 54235

Afghanistan

Suffield 06078

Afghanistan

Watertown 06795

Afghanistan

DeLand 32724

Afghanistan

Building B-15

20102

Afghanistan