-

Able Medical Devices

512 4th St

Gwinn, MI

49841

United States - 30,000 sq. ft. facility

- 906-372-3213

- 60+ employees

- Founded in 2017

- Operating in North America

- Visit Website

Vice President of Business Development

Changes saved

- Equipment/Machinery

- Instruments

- Manufacturing

- Packaging

- Product Development

- Sterilization

- Surface Preparation/Treatments

- Testing

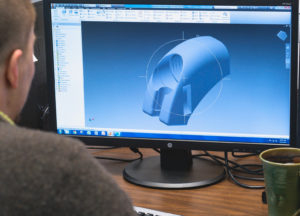

Able Medical Devices is a leader in medical device manufacturing that specializes in instruments and implants that require Swiss-turning and 5-axis machining capabilities. We partner with fast growing OEMs to provide focused service and scalable capacity to support growth. Decades of experience creates a scalable, value-added process, working with customers to meet user needs, while adhering to regulatory standards and driving down lead time and costs.

With an experienced and skilled team, able Medical’s staff provides precision manufacturing that is designed to meet the demands of our healthcare surgeons. The team works diligently to understand our customers’ needs – knowing cost is scrutinized, timelines are tight, and quality is absolute. Able Medical prioritizes transparent communication to minimize any unforeseen roadblocks.

Implant Manufacturing

With an experienced and skilled team, able Medical’s staff provides precision manufacturing that is designed to meet the demands of our healthcare surgeons. The team works diligently to understand our customers’ needs – knowing cost is scrutinized, timelines are tight, and quality is absolute. Able Medical prioritizes transparent communication to minimize any unforeseen roadblocks.

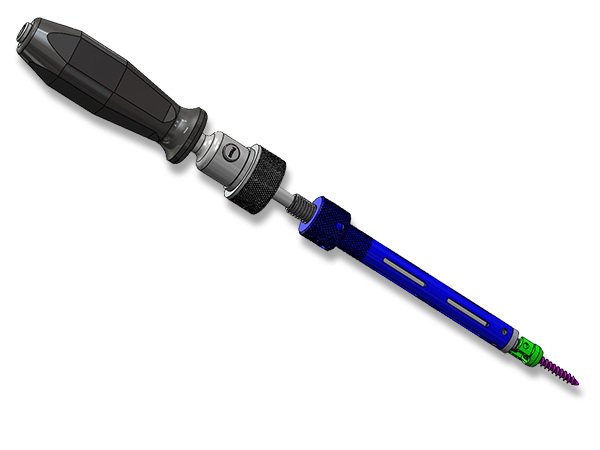

Able Medical manufactures a full range of surgical instruments, from simple to complex assemblies. High quality instruments are the foundation of success for any surgery. To better support our customers, we are fully committed to becoming your supplier of choice for surgical instruments. The same quality and on-time delivery standards applied to implants are utilized for instrument production.

Instrument Manufacturing

Able Medical manufactures a full range of surgical instruments, from simple to complex assemblies. High quality instruments are the foundation of success for any surgery. To better support our customers, we are fully committed to becoming your supplier of choice for surgical instruments. The same quality and on-time delivery standards applied to implants are utilized for instrument production.

Able Medical machines instruments with one or two components to complex applications, which might include 10 or more components with welding and challenging finishes. Our experienced team can serve as your partner in development and production of your complex instrumentation solutions.

Complex Instruments and Assemblies

Able Medical machines instruments with one or two components to complex applications, which might include 10 or more components with welding and challenging finishes. Our experienced team can serve as your partner in development and production of your complex instrumentation solutions.

As experts in medical device machining and precision, Able Medical has an extensive equipment list for your machining needs. Using Lean Principles, projects are delivered on time while exceeding quality standards. Material experience ranges from various grades of steel, aluminum alloys, Cobalt Chrome and Titanium to polymers such as phenolic, UHMWPE and PEEK.

- 9-axis Swiss Turning

- Multi-axis machining

- Grinding

- Wire EDM

- Laser & GTAW welding

- Multisensor/axis CMM

- Complex Assembly

- Laser Marking

- Passivation/finishing

Equipment

As experts in medical device machining and precision, Able Medical has an extensive equipment list for your machining needs. Using Lean Principles, projects are delivered on time while exceeding quality standards. Material experience ranges from various grades of steel, aluminum alloys, Cobalt Chrome and Titanium to polymers such as phenolic, UHMWPE and PEEK.

- 9-axis Swiss Turning

- Multi-axis machining

- Grinding

- Wire EDM

- Laser & GTAW welding

- Multisensor/axis CMM

- Complex Assembly

- Laser Marking

- Passivation/finishing

We provide quality services and products through effective use of our Guiding Principles and Operating Mechanisms. We’re committed to a quality management system that effectively complies with applicable regulations, continuously improves, and ensures that customer requirements are met.

- Defect-free product & services are shipped/provided to customer

- Solutions meet customer needs

- Continuous improvement is practiced in QMS processes

- Establishment/Maintenance/Continuation of ISO 13485 Certification

Quality Policy

We provide quality services and products through effective use of our Guiding Principles and Operating Mechanisms. We’re committed to a quality management system that effectively complies with applicable regulations, continuously improves, and ensures that customer requirements are met.

- Defect-free product & services are shipped/provided to customer

- Solutions meet customer needs

- Continuous improvement is practiced in QMS processes

- Establishment/Maintenance/Continuation of ISO 13485 Certification