President Donald Trump signed an executive order in July to extend the deadline for medical device sterilization facilities to comply with emission limitations for ethylene oxide (EtO) that were imposed by the Environmental Protection Agency (EPA) in April 2024.

The agency’s initial rule was intended to reduce overall EtO emissions from sterilization facilities by 90% and 21 tons per year. Sterilization facilities now have until April 2028 to comply with the directive.

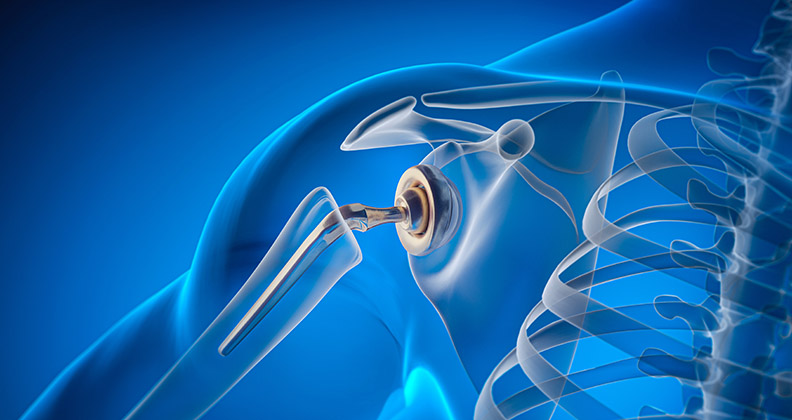

President Trump wrote in the executive order that the EPA’s restrictions present significant challenges for the sterilization industry, noting that roughly half of all sterile medical devices in the U.S. are processed with EtO and that for many products it remains the only viable sterilization method that does not compromise device integrity. As a result, the President wrote, the rule could cause severe supply chain disruptions and restrict access to sterile medical devices.

“There is no other process out there that can handle the volume of medical devices that are currently sterilized using EtO,” said Gary Socola, President of HIGHPOWER Validation Testing & Lab Services. “It will take decades to build an infrastructure for another sterilization method. We were heading down a pathway that was going to negatively impact healthcare in the U.S. for years.”

Socola believes the extension provides OEMs with critical time to source alternatives to relieve pressure from the distribution stream.

Now is a good time to review the benefits and drawbacks of the main options.

Gamma Radiation

Gamma radiation has high penetration power, giving it the ability to sterilize dense materials that are used to make orthopedic devices and making it suitable for high-volume production and complex packaging.

Roy Morgan, President and CEO of Eagle Medical, said gamma radiation is made up of extremely dense, high-energy particles.

“Gamma radiation interacts directly with a molecule’s atomic structure, and because the particles are so small and highly penetrative, they deposit their energy as both vibration and heat,” Morgan said. “Each has a distinct impact on the molecular structure.”

For polymers, which are long chains of hydrocarbons, Morgan said the energy transfer can push the material from an amorphous state into a more crystalline one.

“At the molecular level, that rearrangement can change the polymer’s shape and, in turn, its properties,” he added. “The result might be a material that hardens, becomes brittle, flakes or even changes color — any of which could affect device performance.”

The degree of change depends on the dose, measured in kilograys (kGy). The more energy, the greater the potential for material changes.

Morgan suggests running preliminary tests early in product development to gauge the impact gamma radiation has on a device. Start with simple tests of single materials or early prototypes rather than fully detailed designs.

Expose them to controlled doses and evaluate their cosmetic, mechanical and chemical properties. This upfront approach helps spot potential problems without the expense or delays of testing final products.

Hydrogen Peroxide (H2O2)

H2O2 is easy to deploy, and unlike some other sterilization methods, it doesn’t introduce carcinogenic or mutagenic risks to the process. For most materials, Morgan said, residuals are virtually nonexistent after a sterilization cycle.

H2O2 naturally breaks down into water and oxygen, meaning residuals dissipate quickly —much faster than EtO. “That makes H2O2 not only safer but also more efficient and cost-effective because sterilization cycles are shorter overall,” Morgan said.

He did point to inherent limitations: H2O2 isn’t effective for sterilizing liquids, powders or some cellulosic materials. In those cases, the rapid oxygen release can create a fire hazard.

Still, H2O2 is ideal for specific applications, notably battery-powered and electronic medical equipment. “Unlike other chemicals, H2O2 won’t ignite batteries, corrode electrical leads or damage circuit boards,” Morgan said.

X-ray

According to Betty Howard, Senior Radiation Sterilization Manager at Steris, x-ray sterilization blends aspects of both gamma and electron beam technologies. By using directional photon energy, it delivers a broad spectrum with varying penetration depths.

One of x-ray’s biggest benefits, Howard said, is the shorter exposure time. Faster dose delivery not only shortens processing cycles, but also minimizes the risk of material degradation.

“The growing demand for sterilization, driven by more complex devices and higher production volumes, has exposed the limitations of gamma capacity,” Howard said. “Long processing times and scheduling bottlenecks have made it clear that relying on a single modality is no longer enough.”

Howard sees x-ray as an increasingly important option as a direct alternative to gamma radiation or as a complementary method to help meet demand.

Chlorine Dioxide

Chlorine dioxide gas sterilization is water soluble, so it maintains integrity even when it comes in contact with moisture, according to Emily Lorcheim, Project Manager at ClorDiSys. She said chlorine dioxide’s boiling point of -40°C allows it to behave as a true gas that’s capable of penetrating deep into cracks, crevices and complex surfaces to ensure thorough sterilization. It’s also non-carcinogenic.

“Chlorine dioxide is among the least corrosive sterilization methods available, and it also provides flexibility in processing,” Lorcheim said. “You can adjust gas concentrations to achieve the required dosage, tailoring the process for material compatibility or faster cycle times.”

Unlike EtO, chlorine dioxide leaves behind benign byproducts and has been observed to reduce endotoxin levels, further supporting its use as a safe and effective sterilant.

“There’s minimal concern about residuals with chlorine dioxide, and it demonstrates excellent material compatibility across most tested surfaces,” Lorcheim said.

Tensile strength testing on glass-filled polymers and unfilled resins confirmed that even at high dosages, chlorine dioxide produced no noticeable effects on material integrity. These results demonstrate that chlorine dioxide is effective as a sterilant and gentle on a wide range of materials, Lorcheim said.

The sterilization method is compatible with cellulosic materials, works in multi-pellet chambers and can handle complex devices and large volumes.

“It typically does not require heating, and it produces little to no emissions, making it both safe and environmentally friendly,” Lorcheim said.

DC

Dan Cook is a Senior Editor at ORTHOWORLD. He develops content focused on important industry trends, top thought leaders and innovative technologies.