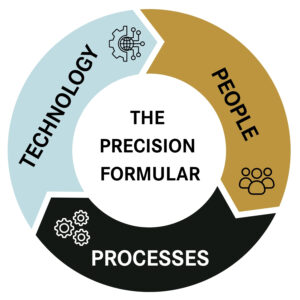

In today’s orthopedic industry, choosing the right contract development and manufacturing organization (CDMO) partner is critical for OEMs to strengthen market competitiveness and ensure an efficient, reliable supply chain. This is especially relevant amid competitive pressure, rising regulatory demands, and shorter development cycles. But what truly defines manufacturing and what’s at the core of every CDMO partner? Is it cutting-edge technology, experienced people, or optimized processes?

At Komet Medical, we have explored this question and defined the answer as a “formula.” We see long-term success in orthopedics as the result of the seamless interaction of all three elements. Technology alone cannot deliver superior results without the knowledge and experience of skilled people. Processes achieve their full potential only when supported by the right team and the right technology. Combined under one roof, these elements form the foundation for precision, reliability, and speed — and with it, the value OEMs require.

People – The Foundation of Precision and Quality

At Komet Medical, we believe people are more than machine operators —they are central to production success. Technology shows its true potential only in the hands of trained professionals who can apply it effectively. Our teams have the knowledge and experience not only to operate processes, but also to design, optimize, and safeguard them. Expertise in material science, CAM programming, manufacturing strategies, and early risk identification is complemented by ongoing improvement of workflows.

That is why our production employees typically complete a three-and-a-half-year training program combining theoretical instruction with practical application. This foundation develops professionals who understand both technical principles and real-world production practices. Low employee turnover and continuous training ensure that know-how and practical experience are retained and expanded. With more than 100 years of experience, we know that training and hands-on expertise are key to mastering complex designs, tight tolerances, and demanding materials.

Processes – Structure for Reliability, Agility and Performance

Standardized processes at Komet Medical provide the basis for efficient, reliable operations — but true excellence comes from daily, direct interaction where value is created. Through our shop floor management system, we ensure that processes are not just documented, but lived and continuously improved.

Shop floor management — from identifying deviations to hands-on coaching and tracking shared goals — enables leaders to manage performance where it really happens: in direct interaction with employees on the line. This approach promotes transparency, accountability, and the nimbleness to respond to new requirements while maintaining stability.

Our process landscape is designed to combine standardization with adaptability. This allows us to meet individual customer requirements with precision and without compromising on quality, safety, or delivery reliability.

Technology – Driving Efficiency and Competitiveness

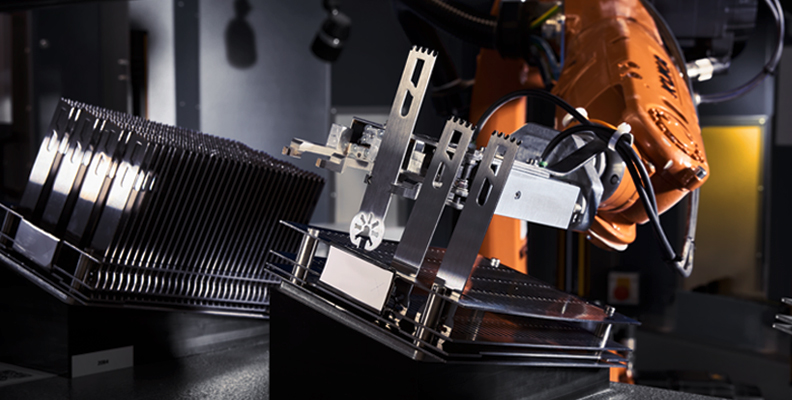

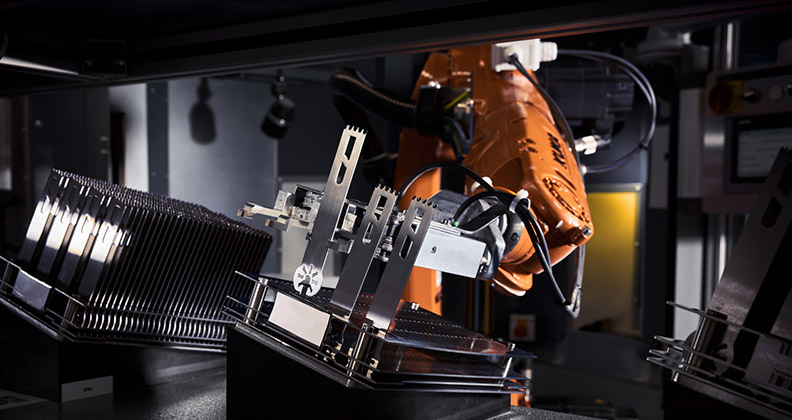

Investment in smart manufacturing and AI is no longer a future concept; it is a critical part of every forward-looking production strategy. In our view, it is one of the most important factors in strengthening both competitiveness and technological capability.

The goal of smart manufacturing is to enable production processes to run as autonomously as possible, with minimal manual intervention. To move toward this goal, machines and systems must be capable of monitoring themselves and the process outcomes, and, if necessary, initiating corrective actions. There is also a trend toward standardized digital interfaces, enabling machines to interact with other units, such as autonomous mobile robots that deliver raw materials or collect finished parts.

Connected systems, real-time monitoring, data-driven analytics, and state-of-the-art CNC machines are essential elements of a modern production strategy.

Another key component is CAD/CAM integration, which transfers digital design data seamlessly into CNC programs. This shortens development times and minimizes potential sources of error.

With increasing market demands and growing product complexity, we embrace the opportunities of digitization and consistently invest in digital solutions to make manufacturing more precise, efficient, and scalable.

Precision Through Balance

A strong CDMO is defined not by a single factor, but by the balance of qualified people, optimized and secure processes, and advanced technology. At Komet Medical, we are convinced that this is the combination that makes the difference. It creates precision, flexibility, reliability, and speed.

This precision formula has proven itself in our decades of practice and it remains our promise for the future.

Komet Medical specializes in developing and manufacturing cutting, fixation and insertion instruments. Visit Komet Medical’s listing in the Supplier Directory for more information about the company’s capabilities.