Lisa Lattanza, M.D., a renowned expert in personalized 3D surgical planning to correct upper extremity deformities, arrived at the Yale School of Medicine in 2019 and began working with colleagues to develop the 3D Collaborative for Medical Innovation (3DC), a program focused on advancing the clinical applications of 3D printing. Five years later, Dr. Lattanza performed Yale’s first in-house personalized repair of a distal radius malunion involving 3D surgical planning and 3D-printed personalized surgical guides.

“During the repair, the radius must rotate over the ulna,” said Dr. Lattanza, Chair and Ensign Professor of Orthopaedics and Rehabilitation at Yale. “If one of the bones doesn’t have the correct contour, it can’t rotate properly around the other. As a result, the arm can’t turn back and forth. In some cases, the patient can lose the ability to extend or flex the elbow.”

Dr. Lattanza said it’s difficult for surgeons to appreciate the full extent of the deformity in 2D imaging because they lose sight of the axial plane, which involves looking at the bone from a sideways or top-down view. Advanced 3D imaging allows surgeons to plan for a nearly perfect correction.

Patients at Yale who are candidates for repairs of distal radius malunion undergo CT scans of both arms. A 3DC engineer uploads the scans into a specialized software program and manipulates the images, creating a mirror image of the injured side and comparing it directly to the uninjured side for a normal reference.

Once the images are pre-processed and formatted for viewing, the engineer holds a virtual meeting with the operating surgeon and presents the images of the deformity. The surgeon assesses the deformity, determines the best way to correct it and discusses the particulars of the case with the engineer.

“This collaboration allows surgeons to leverage their expertise in anatomy and surgical goals, while the engineer applies their expertise in manipulating the images, angles and geometry to create the most precise plan for correction,” Dr. Lattanza said.

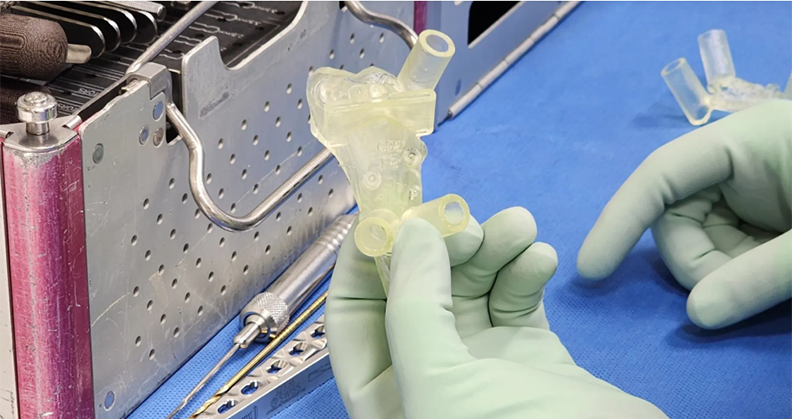

The engineer then creates a detailed surgical plan that includes the types and sizes of plates that will be used and where they should be placed. They 3D print preoperative bone models, post-correction models and personalized patient guides.

“The guides fit on the patient’s bone in only one place — where the deformity is — and help us determine where to drill the holes,” Dr. Lattanza said. “By bringing 3D printing technology in-house, we’ve made it much more accessible. We’re also able to provide this service at about a third of the cost compared to what an outside 3D printing vendor would charge. As our team gains experience in the process, we expect the savings to increase.”

The Engineering Side

Engineers seeking to take their careers to the next level could benefit from advanced degrees that focus on traditional studies, as well as evolving technologies.

Yale’s School of Engineering provides hands-on applications of engineering fundamentals, and created a Master of Science in Personalized Medicine and Applied Engineering that aligns with 3DC.

The collaboration between engineering and healthcare providers, as well as the school’s focus on team-based problem solving, established a foundation in biomedical device design that equips medical professionals with engineering knowledge and engineering professionals with medical knowledge.

The overall goal is to prepare medical and engineering students to enter the orthopedic industry with a deeper understanding of the product development process, according to Vincent Wilczynski, Ph.D., Deputy Dean of the Yale School of Engineering & Applied Science and the James S. Tyler Director of the Yale Center for Engineering Innovation & Design.

“On the engineering side we have the facilities, staff and culture to support open-ended initiatives,” Dr. Wilczynski said. “On the healthcare side, Dr. Lattanza and her colleagues are the subject matter experts who provide the intellectual capital and guidance on the medical products that are needed.”

Yale’s engineers provide guidance on the “how” and its orthopedic surgeons offer the expertise on the “what” that needs to be done to achieve improved patient outcomes.

Surgeons often recognize unmet clinical needs, but the solutions typically lie outside their domain. “That’s where engineering and computer science come into play,” Dr. Wilczynski said. “Once the problem is identified, bringing together medical professionals and engineers can lead to innovative solutions. This interdisciplinary collaboration is not only exciting, but also deeply impactful for the students involved in our program.”

Dr. Wilczynski said engineering students become more motivated and engaged in their work when they relate problems to real-life scenarios.

“Solving fundamental equations for stress is an intellectual exercise on its own, but applying those equations to the stress in your hip, or a loved one’s hip, adds significant personal meaning,” he said. “It makes the fundamental engineering concepts come alive, whether it’s in analysis, CAD design or the fabrication of medical devices. The more students can see the real-world applications of what they’re learning, the more meaningful their education becomes.”

The program also increases the awareness and benefits of working in medical device engineering. “Not only does it equip engineers with valuable skills, but it also broadens their understanding of the possibilities within the orthopedic industry,” Dr. Wilczynski said. “It provides an impressive credential that establishes them within the industry and opens doors for job opportunities.”

The infrastructure of Yale’s 3D printing program is now in place in the hospital and engineering school. Healthcare professionals can access advanced 3D printing capabilities and computational design software, which were previously available only at the engineering school.

The 3DC team is working on extending partnerships with other interested universities and corporate partners. Dr. Wilczynski is excited by the potential for Yale to become a model for other universities.

“The program we’ve developed could fill a critical need, not just nationally but globally,” he said. “Our goal is to share our successes and learnings to inspire other institutions around the world to adopt similar models, creating a wider impact.”

DC

Dan Cook is a Senior Editor at ORTHOWORLD. He develops content focused on important industry trends, top thought leaders and innovative technologies.