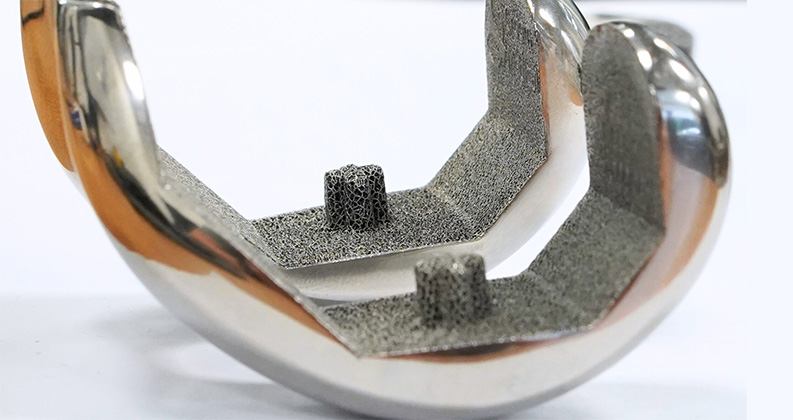

Norman Noble has implemented cutting-edge robotic electropolishing technology at one of its Ohio facilities. This state-of-the-art system is a fully automated, closed-loop process that eliminates human intervention, ensuring repeatability and efficiency in finishing metallic-based medical implants.

“The addition of fully automated robotic electropolishing aligns with our strategic initiatives to enhance quality and reduce costs for our customers,” said Eric Lehuta, Director of Engineering at Norman Noble. “By eliminating human variability, we achieve the consistency and precision required for intricate stent designs and other high-performance medical implants. This advanced automation ensures unparalleled repeatability and process control, ultimately improving manufacturing efficiency and delivering superior product quality to our customers.”

The company’s continued investment in robotics highlights its dedication to pushing the boundaries of manufacturing innovation, optimizing production workflows and delivering superior quality products for its customers.

Source: Norman Noble

JAV

Julie A. Vetalice is ORTHOWORLD's Editorial Assistant. She has covered the orthopedic industry for over 20 years, having joined the company in 1999.