Bunion repair is undergoing a significant evolution, with new products introducing advanced ways to correct bony bumps on the big toe with as little disruption to neighboring anatomy as possible. The focus on improved bunionectomy outcomes represents an untapped market that’s primed for innovation and growth.

A flurry of acquisitions during the pandemic consolidated much of the foot and ankle business among the top orthopedic companies, but opportunities remain for mid-level players in the bunion subsegment. Treace Medical, which specializes in bunion correction solutions, said only about half of the 1.1 million candidates for bunionectomy in the U.S. undergo the procedure each year because of concerns about the invasiveness of conventional surgical approaches.

Osteotomies account for approximately 70% of the overall procedure volume in the U.S. bunion market, according to Treace Medical, which reports only 10% to 15% of the procedures are performed using minimally invasive surgery (MIS) techniques.

Minimally invasive bunion repairs appeal to surgeons and patients but are technically challenging to perform and are associated with a significant learning curve, which has limited their widespread adoption. Enovis, which joins Treace Medical as one of the top performers in foot and ankle, recognizes this issue and is reimagining the ways medical training is delivered to surgeons. The company’s approach is focused on creating a comprehensive ecosystem around streamlined bunion treatments.

Shannon Cummings, Global Vice President of Marketing for Enovis Foot & Ankle, said the company is investing heavily in the development of implant technology, surgical techniques and instrumentation around the procedure.

“We believe a new approach to education surrounding minimally invasive surgical techniques is necessary,” he said. “By enhancing communication and developing programs and technologies tailored to the surgical experience, we aim to improve patient outcomes.”

Consistency Is Key

Cummings characterized the current state of minimally invasive bunion repair as in the “art realm” where surgical techniques vary widely, making it challenging to achieve consistent results. He also noted an evolving consensus among surgeons regarding the best treatment options.

“Twenty years ago, opinions on bunion surgery were all over the board,” he said. “We’re now seeing a consolidation of thought around which procedures deliver the best outcomes for patients. This unified direction is a positive step forward for the field.”

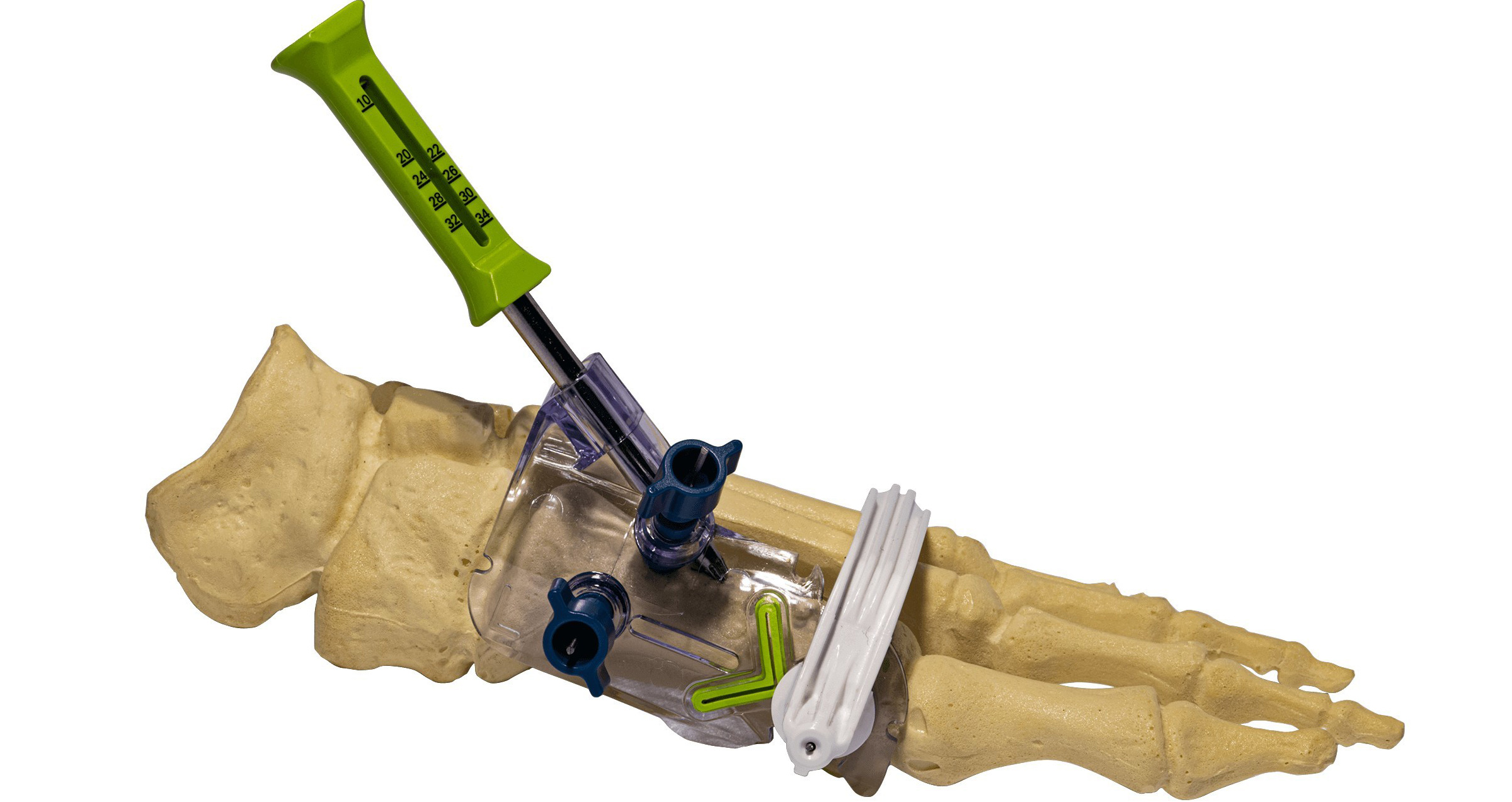

Enovis has responded to the changing market dynamics by developing a bunionectomy guidance system that’s aimed at making MIS accessible to more surgeons. Cummings highlighted the company’s launch of the Tarsoplasty Percutaneous Lapidus System, a next-generation platform that combines advanced instruments and implants to deliver precise and reproducible percutaneous bunionectomy outcomes.

“The clinical data supporting the Tarsoplasty System highlights the effectiveness of the percutaneous approach to hallux valgus correction,” Cummings said.

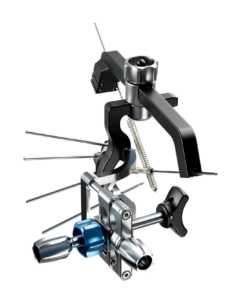

RELJA Innovations is among the orthopedic companies that’s focused on transforming bunionectomy with faster, safer and minimally invasive solutions. Founder and CEO Rob Amiot, D.P.M., spearheaded the design of two products aimed at improving bunion surgery outcomes: the RELJA MIS Chevron Bunion System and RELJA Clamp.

The RELJA MIS Chevron Bunion System introduces a precision cutting guide that enables surgeons to perform reproducible osteotomies. It incorporates a V-shaped cut that’s made with a minimally invasive approach through a 1 cm incision.

“The system utilizes a radiolucent platform with a radiopaque cutting guide,” Dr. Amiot explained. “This not only aids precision in osteotomies but also ensures accurate screw placement, enhancing the reproducibility and reliability of the procedure.”

The RELJA Clamp offers a streamlined method for correcting bunion deformities in three planes, eliminating the need for multiple incisions. The radiolucent clamp simplifies fixation, allowing surgeons to hold the correction in place while hardware is applied.

“The clamp is quick and easy to apply, reducing surgical complexity and potentially shortening operating room time,” Dr. Amiot said. “Its agnostic design ensures compatibility with RELJA-branded hardware and others on the market, providing flexibility in surgical technique for surgeons.”

Dr. Amiot noted that traditional bunion surgeries often involve large incisions and significant soft tissue disruption, whereas RELJA’s MIS solutions minimize damage to surrounding tissue.

“As a surgeon who has performed thousands of bunion procedures, I found many existing products overengineered, overly invasive and unnecessarily complicated,” Dr. Amiot said. “Our products focus on minimal incisions and limiting soft tissue damage, leading to faster recoveries, less pain and better outcomes.”

RELJA Innovations prioritizes the use of state-of-the-art materials and techniques to enhance the surgeon’s experience while keeping costs manageable. According to Dr. Amiot, RELJA’s success stems largely from the fact that its products are designed by surgeons, for surgeons.

“Many other companies rely on engineers to design a product, which a surgeon then modifies,” he said. “We’ve taken a completely different approach. Although we’re still a small company, we’re experiencing significant growth because surgeons see our products and think, ‘This makes sense — why didn’t anyone else think of it?’”

Beyond the trend toward minimally invasive bunion procedures, Dr. Amiot noted that device-makers are increasingly focused on building efficiencies into existing solutions rather than creating entirely new ones.

“A lot of companies now have plates and screws, but the real innovations aren’t necessarily in the plates or screws themselves,” he said. “Instead, the advancements lie in developing tools — clamps, instruments or other modalities — that help surgeons achieve better correction, faster procedures and quality outcomes in less invasive ways. Over the next decade, we’ll see more of these solutions making surgery simpler and more effective.”

The Tarsoplasty Percutaneous Lapidus System from Enovis includes instruments and implants designed for a guided and reproducible percutaneous procedure.

Leave No Trace

While traditional bunion treatments rely on plate-and-screw implants, OSSIO is pioneering a different approach with its OSSIOfiber bio-integrative fixation implants.

OSSIOfiber screws and trimmable threaded fixation nails have already been used successfully in minimally invasive bunion repair by a select group of surgeons, even though the company has yet to release specialized instrumentation for inserting the implants. OSSIO will release the instruments later this year.

OSSIO’s OSSIOfiber small compression staples are specifically designed for hand and foot procedures, including bunion repair via Akin osteotomy. This new product line expands the company’s growing portfolio, which includes larger compression staples, suture anchors, trimmable fixation nails and a hammertoe fixation system.

All OSSIOfiber implants, including the compression staples for bunionectomy, feature the same bio-integrative design that’s based on the company’s proprietary polymeric mineral fiber matrix, which promotes rapid bone in-growth and regeneration that eventual replaces the implant.

The company’s Intelligent Bone Regeneration Technology delivers a mechanical strength that’s stronger than cortical bone while facilitating natural healing, according to OSSIO CEO Brian Verrier. “The result is stability and mobility without the use of a permanent implant,” he said.

Verrier highlighted the ease of use and compression strength of OSSIOfiber staples, which matches or exceeds that of nitinol staples, as key advantages. “Our mission is to transform the surgical experience for patients requiring internal fixation,” Verrier said. “This includes bunion patients, who stand to benefit from solutions that combine high performance with a bio-integrative design.”

Bradley Lamm, D.P.M., Director of the Foot and Ankle Deformity Center at the Paley Institute in West Palm Beach, and Selene Parekh, M.D., a professor of orthopedic surgery specializing in foot and ankle procedures at the Rothman Institute, were among the first surgeons to use OSSIO’s small compression staples.

“The design of the staples makes them easy to insert during Akin bunion repair,” Dr. Lamm said. “This new product line expands the options for surgeons to use cutting-edge fixation technology that is gradually replaced by bone over time, eliminating the inherent risks of metal implants. Patients appreciate the no-metal footprint as much as surgeons do.”

Dr. Parekh also emphasized the advantage of using a material that naturally degrades in the body instead of remaining permanently in place.

“I’ve used many types of small compression staples during my career,” he said. “For me, the most compelling reason to use bio-integrative implants is the ability to eliminate metal without compromising compression strength. Not having to worry about hardware irritation after an Akin bunion repair — or the need for a secondary surgery to remove an implant— is a significant benefit for patients and surgeons.”

Advancements in bunionectomy techniques will increase the overall volume of bunion procedures in the coming years, according to Verrier.

“Fear of postoperative pain and metal hardware has historically made some patients hesitant to undergo surgical repair,” he explained. “However, these concerns are alleviated by minimally invasive surgical techniques and bio-integrative implants, which reduce recovery time and effectively eliminate the risk of long-term complications.”

Verrier predicted that the practice of inserting metal screws into a foot through a small incision and calling it MIS will soon feel outdated.

“The trend toward minimally invasive bunion repair is evolving,” he said. “Patients are increasingly demanding a minimal footprint not only during the procedure but also in the long term, with no implant left behind.”

PM

Patrick McGuire is a BONEZONE Contributor.