While 3D printing creates opportunities for bone to grow through orthopedic implants instead of simply attaching to their surfaces, the addition of regenerative therapies to these devices could make the body heal in a faster, more precise way. The startup Theradaptive is developing new biomaterials, including protein-based material-binding variants that target tissue and bone regeneration. One of their latest efforts is focused on creating 3D-printed implants.

In 2023, Theradaptive and 3D Systems established a commercialization and funding agreement. Theradaptive will use 3D Systems as their exclusive printing partner, and 3D Systems invested $8 million in the startup. The collaboration includes coating 3D-printed devices with the AMP2 regenerative protein that Theradaptive has become known for in the orthopedic market.

Theradaptive’s platform protein technology was developed by Luis Alvarez, Ph.D., and his lab at the Massachusetts Institute of Technology. He and his team sought to solve the problem of how to target a therapeutic to a specific area of the body.

“Proteins are a class of therapeutics that are commonly used to treat diseases, but there’s no easy way to keep them in a specific place in the body,” Dr. Alvarez told us in 2022. “Our technology allows us to do that with not just the protein we’re using for spine applications, but for virtually any protein you want to keep in a specific place in the body for a long period of time.”

The company has developed material-binding variants of recombinant proteins for use in over a dozen clinical indications, ranging from spinal fusion to soft tissue repair to chemotherapeutics. The protein can coat an implant during a 10- to 15-minute dipping procedure, which is a simple manufacturing technique that doesn’t require chemistry or non-traditional processing.

“We make the new protein in bioreactors or fermentors and then purify it from there,” Dr. Alvarez said. “Then, we combine that protein with the implant in another process and that makes the final product — an implant with the fully genetically encoded protein.”

Theradaptive has received three Breakthrough Device Designations from FDA for the use of its OsteoAdapt SP interbody implant for anterior lumbar, transforaminal and posterolateral fusions. Further, the company has developed in-house materials that can be 3D-printed and coated with their protein.

We spoke with Dr. Alvarez, CEO and Founder of Theradaptive, about why he chose 3D printing as the next step for the company and why he’s targeting the spine market.

Why does 3D printing interest you?

Dr. Alvarez: 3D printing is the next frontier in regenerative medicine. It allows for anatomical precision when regenerating tissue. Additionally, printing patient-specific products based on radiology data or other types of imaging files makes for the ultimate solution to the problem of regenerating bone.

Startups often seek the help of strategic partners. How did your relationship with 3D Systems come about, and what projects will you focus on together?

Dr. Alvarez: 3D Systems has a history in orthopedics and spine. That work is focused on metals and, recently, polymers. Traditionally, they have not been involved in regenerative or resorbable implants.

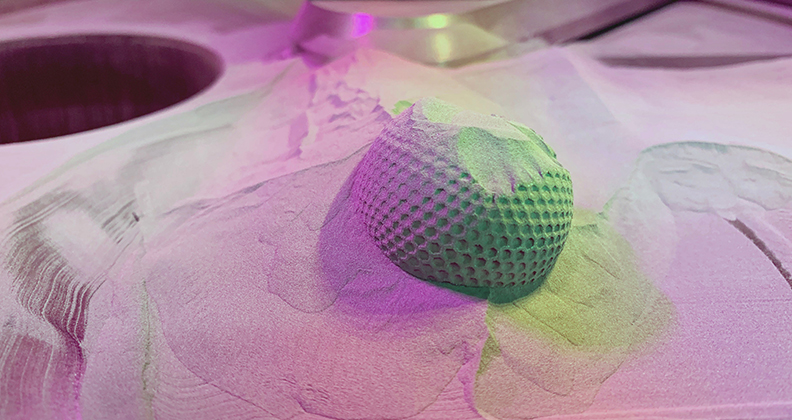

We developed OrthoTex to print regenerative implants. OrthoTex is a flexible ceramic composite that can be 3D printed. 3D Systems thought it was attractive, and we were drawn to their scale and penetration in the market. They invested in Theradaptive, and we plan to launch products in craniomaxillofacial, spine and orthopedics.

OrthoTex is also compatible with the protein that we make. We can load our regenerative AMP2 protein onto the OrthoTex material. Our product concepts also include making 3D-printed components that we load with OsteoAdapt, our cottony material. Our platforms are interoperable.

Your first indication for OsteoAdapt is spine, and you’ll be partnering with 3D Systems on spine implants. Why did you decide to prioritize that market?

Dr. Alvarez: First, the spine space has many patients who need new solutions. We think the technology that we’re developing will help address that need. Second, there’s a lot of innovation happening in spine that requires intricate manufacturing, and that’s where 3D printing shines.

Orthobiologics have a significant role in spine. What role will regenerative proteins and therapies play in the future of the market?

Dr. Alvarez: If you look at the field today, there’s only one recombinant protein on the market, BMP-2, which is very potent and difficult to use precisely. We re-engineered the protein to be bound on and within the implant, which allows us to deliver it with greater precision. We can control where bone will form more precisely. Our protein also provides longer persistence. While BMP-2 diffuses away, AMP2 remains in place. Those two important factors have led to the superior outcomes we’ve seen in our preclinical studies.

OsteoAdapt, which contains the AMP2 protein, has beaten the standard of care in all of the 20 preclinical studies we’ve conducted. We were able to completely regenerate 5cm segmental defects in a long bone study and achieve spine fusion within six weeks in a spine study.

What can we expect from Theradaptive in the next six months?

Dr. Alvarez: Our activity is focused on starting in-human clinical trials in the U.S., Australia and a still-to-be-disclosed country. We’re also launching 3D-printed products with 3D Systems and aim to bring FDA 510(k) and PMA devices to market.

CL

Carolyn LaWell is ORTHOWORLD's Chief Content Officer. She joined ORTHOWORLD in 2012 to oversee its editorial and industry education. She previously served in editor roles at B2B magazines and newspapers.