VISIONx has released version 16.0 of its VisionGauge software for the VisionGauge Digital Optical Comparator, expanding capabilities that are suitable for the inspection of orthopedic implants.

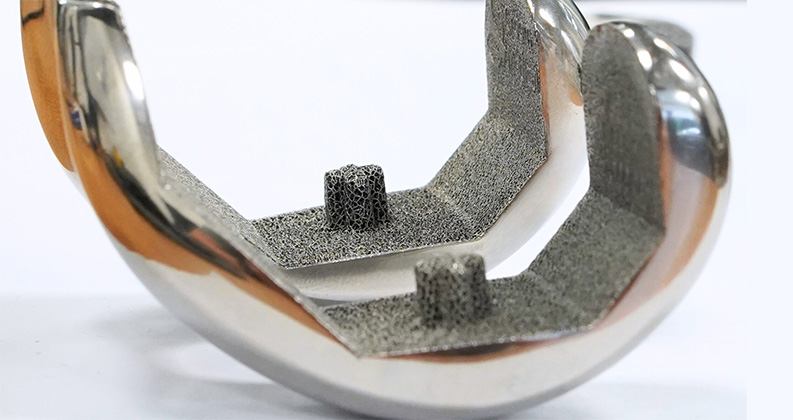

The VisionGauge Digital Optical Comparator was initially developed in close collaboration with a large medical OEM, specifically to meet the requirements of orthopedic implant inspection & measurement. The system is fast, accurate and requires virtually no programming. It works directly on the shop floor and can be used to create automated inspection reports and collect complete device history. It can collect images, measurements, pass/fail results, statistics with graphs & charts and can easily send all inspection data to a central database.

And now, with the new version 16.0 of the VisionGauge software, the system has significantly expanded capabilities for the inspection of orthopedic implants, including:

- Dedicated high-accuracy thread measurement tools (perfect for bone screws, for example)

- Expanded patented CAD Auto-Align and CAD Auto-Pass/Fail tools that can be applied to very large parts, that extend beyond the optical field of view (such as orthopedic nails and rods, used to lengthen and stabilize bones)

- New powerful advanced Auto-Pass/Fail Analysis and Reporting tools that allow operators to easily carry out in-depth review, analysis exploration, and labeling of CAD Auto-Pass/Fail results. These new advanced tools are perfect for meeting the exacting documentation requirements for medical implant inspection and measurement and collecting complete device history.

- An enhanced CAD Fitting tool that automatically refines CAD Auto-Align results in some difficult applications, to achieve even better results.

- A number of general enhancements including various performance enhancements (to speedup execution), enhanced data export capabilities, many new measurement tools, improved line-fitting tools, etc.

The system’s unique patented CAD Auto-Align and CAD Auto-Pass/Fail tools allow the system to automatically compare a part to its CAD file and produce results of very high accuracy, completely automatically and with absolutely no operator dependence or subjectivity. With the VisionGauge Digital Optical Comparator you can use your CAD data directly and completely do away with overlays or Mylars. The VisionGauge Digital Optical Comparator is very broadly applicable and has no limitation on part geometry. It is perfectly suited for a wide range of implants, both metal & plastic.

The VisionGauge Digital Optical Comparator produces demonstrated accuracy down to +/-0.0001″ in real-world applications, right on the shop floor. The system can display deviations from nominal completely automatically. This allows operators to quickly and easily locate areas that are outside of tolerance. Furthermore, results are 100% consistent results between users as there is no operator-to-operator variation. Finally, VisionGauge Digital Optical Comparators are very fast and yield significant gains in throughput.

Source: VISIONx INC.

JAV

Julie A. Vetalice is ORTHOWORLD's Editorial Assistant. She has covered the orthopedic industry for over 20 years, having joined the company in 1999.