-

Komet Medical – Gebr. Brasseler GmbH & Co KG

6602 Abercorn St

Suite 200

Savannah, GA

31405

United States - >540,000 sqft production area and office space

- 912-581-1711

- >1350+ employees

- Operating in Europe, North America, South America

- Visit Website

Changes saved

- Component Parts

- Instruments

- Manufacturing

- Materials/Metals

- Packaging

- Product Development

- Regulatory/Quality Assurance

- Sterilization

- Surface Preparation/Treatments

- Testing

Komet Medical, part of the Gebr. Brasseler Germany Group, is one of the world’s leading independent CDMOs, offering specialized services in surgical cutting and fixation instruments. With over 100 years of experience and deep expertise, we offer comprehensive support throughout your entire product lifecycle. In essence, we are your partner from concept to completion.

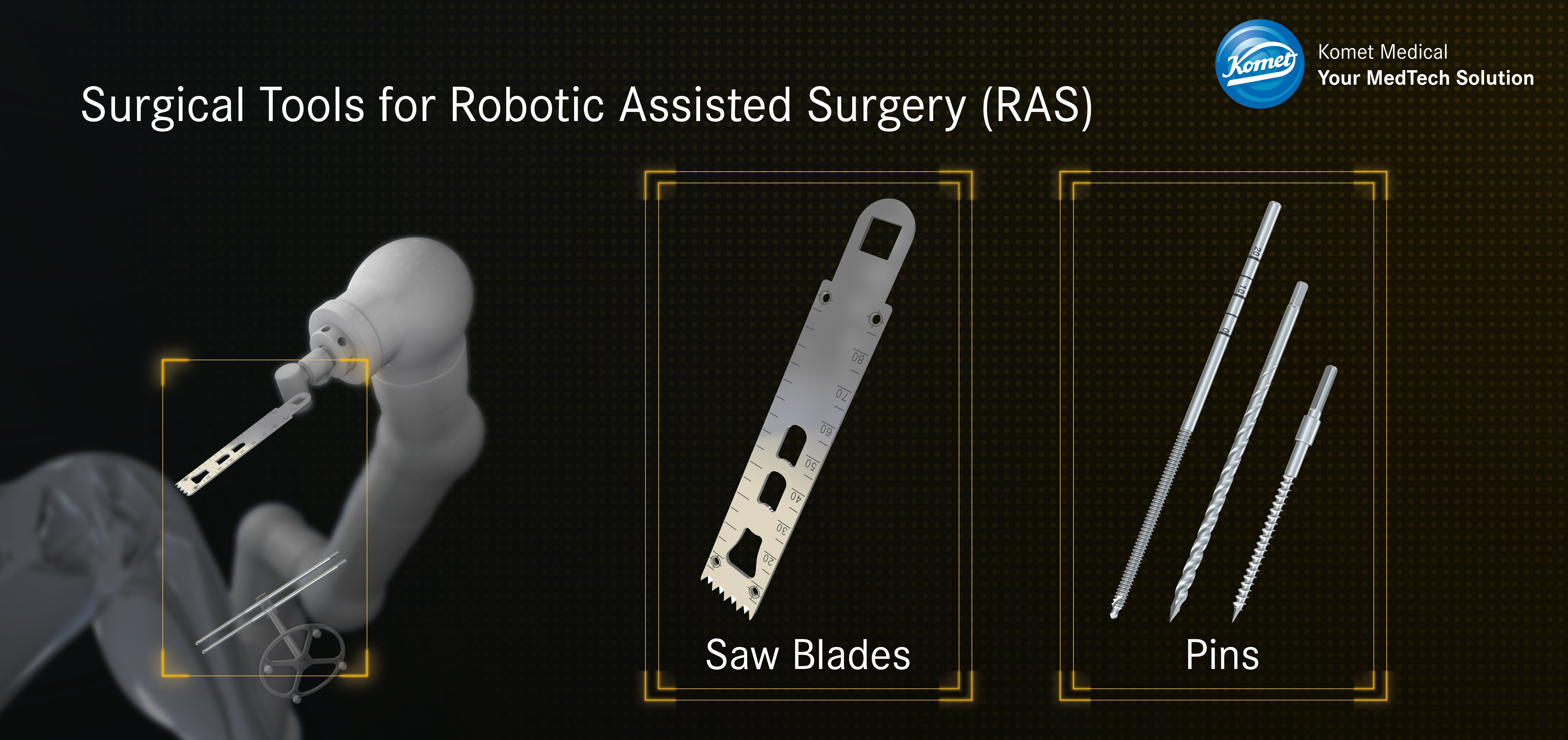

We specialize in the development and manufacturing of a wide range of surgical cutting and fixation instruments, including:

- Saw blades

- Bone fixation pins & screws for cutting blocks and arrays (RAS)

- Drill bits, reamers, taps

- MIS burrs for foot and ankle

- Rotary burrs (steel, carbide, diamond coated)

For traditional and even robotic assisted surgery (RAS), covering:

- Knee & hip

- Foot and ankle

- Trauma and Extremities

- Spine

Products and Markets

We specialize in the development and manufacturing of a wide range of surgical cutting and fixation instruments, including:

- Saw blades

- Bone fixation pins & screws for cutting blocks and arrays (RAS)

- Drill bits, reamers, taps

- MIS burrs for foot and ankle

- Rotary burrs (steel, carbide, diamond coated)

For traditional and even robotic assisted surgery (RAS), covering:

- Knee & hip

- Foot and ankle

- Trauma and Extremities

- Spine

- 6-axis grinding machines

- CNC-controlled Swiss-type turning machines

- Turning-milling centers with 5 simultaneous axes

- Gun drilling

- High-performance laser systems for metal cutting

- Tooth-setting machines for saw blades

- Specialized systems for surface treatment (deburring/abrasion)

- Laser welding

- Anodizing

- Electropolishing

- Heat treatment/hardening

- Galvanizing/diamond coating. 12 grain sizes from 25 µm (500 Mesh) to 851 µm (20 Mesh)

- Ultrasonic cleaning

- Passivation (ASTM A967)

- EDM wire cutting

- Wire processing

- CMM testing

- Electro-dynamic testing machines (according to ASTM F1717, ASTM F2193, ISO 12189)

- Torsion testing machines (according to ASTM F543, F1717, ASTM 1789)

- Gold coating

- Color marking

- Blasting systems (matting) for rotating instruments

- Laser marking

- ISO Class 8 cleanroom with validated packaging solutions

In-house Manufacturing Capabilities:

- 6-axis grinding machines

- CNC-controlled Swiss-type turning machines

- Turning-milling centers with 5 simultaneous axes

- Gun drilling

- High-performance laser systems for metal cutting

- Tooth-setting machines for saw blades

- Specialized systems for surface treatment (deburring/abrasion)

- Laser welding

- Anodizing

- Electropolishing

- Heat treatment/hardening

- Galvanizing/diamond coating. 12 grain sizes from 25 µm (500 Mesh) to 851 µm (20 Mesh)

- Ultrasonic cleaning

- Passivation (ASTM A967)

- EDM wire cutting

- Wire processing

- CMM testing

- Electro-dynamic testing machines (according to ASTM F1717, ASTM F2193, ISO 12189)

- Torsion testing machines (according to ASTM F543, F1717, ASTM 1789)

- Gold coating

- Color marking

- Blasting systems (matting) for rotating instruments

- Laser marking

- ISO Class 8 cleanroom with validated packaging solutions

Our services are customized to meet your project’s stage of development and specific needs, ensuring the best possible solutions from concept to a ready-to-sell medical device.

- Project management

- Design & development

- Manufacturing capabilities

- Sterile & non-sterile packaging

- Quality & regulatory support

- Serial production with supply chain solutions

Our Services - Tailored to Your Project

Our services are customized to meet your project’s stage of development and specific needs, ensuring the best possible solutions from concept to a ready-to-sell medical device.

- Project management

- Design & development

- Manufacturing capabilities

- Sterile & non-sterile packaging

- Quality & regulatory support

- Serial production with supply chain solutions

Our service portfolio goes beyond traditional CDMO offerings, delivering additional value for OEMs. A standout feature of our CDMO+ service is private label solutions, where we assume the role of legal manufacturer, while the OEM markets the product under its own brand. This provides OEMs with two major benefits: enhanced brand perception and regulatory relief.

In Addition, with over 1,100 products, OEMs can rely on one of the largest available standard assortments of surgical cutting and fixation instruments – all in stock.

CDMO+ - Our + for OEMs

Our service portfolio goes beyond traditional CDMO offerings, delivering additional value for OEMs. A standout feature of our CDMO+ service is private label solutions, where we assume the role of legal manufacturer, while the OEM markets the product under its own brand. This provides OEMs with two major benefits: enhanced brand perception and regulatory relief.

In Addition, with over 1,100 products, OEMs can rely on one of the largest available standard assortments of surgical cutting and fixation instruments – all in stock.