Orthopedic instruments and implants require precise surface finishing to ensure safety, strength and longevity. While the specific surfacing goal and technique vary, the stringent requirements must always be met.

Orthopedic instruments and implants require precise surface finishing to ensure safety, strength and longevity. While the specific surfacing goal and technique vary, the stringent requirements must always be met.

From stainless steel dental drill heads that require deburring and surface smoothing to stainless steel tweezers that require surface cleaning and texturing after forging/grinding and induction welding, medical instruments must be sterile yet strong and able to pass rigorous inspection upon production as well as in the field.

Achieving the desired finish for orthopedic instruments can pose considerable technical challenges. That’s why close cooperation between orthopedic device manufacturers and qualified surface treatment experts is essential during the development and prototyping phase.

Let’s examine the capabilities that mass finishing and shot blasting offer orthopedic implants. Additionally, we’ll review how Rosler can develop a precise and repeatable finishing process to meet your unique challenges and goals.

Mass Finishing

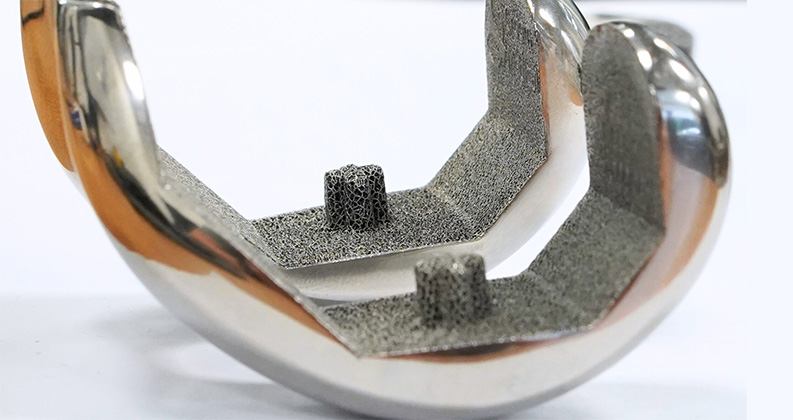

Mass finishing is a universal finishing technology that can be used for a multitude of surface treatment operations. The process is ideal for spinal implants and instruments.

Mass finishing is a universal finishing technology that can be used for a multitude of surface treatment operations. The process is ideal for spinal implants and instruments.

Applicable processes include:

- Deburring and edge radiusing to grind off sharp burs and round edges.

- Surface cleaning to remove scale from work pieces after forging, heat treatment or casting as well as oil, coolant, shavings and other surface impurities.

- Surface smoothing, often referred to as “cut-down,” in preparation for polishing, plating and electro-polishing.

- Polishing for appearance and stain resistance in addition to high-gloss polishing.

Mass finishing is equally suitable for surface smoothing and high gloss polishing down to Ra = 0.8 micro inches.

Shot Blasting

Small metal or mineral pellets are thrown onto the surface of a workpiece at speeds of 200-800 feet/second (60-250 m/s) in shot blasting. The impact on the workpiece surface produces the desired cleaning, peening or texturing effect.

Small metal or mineral pellets are thrown onto the surface of a workpiece at speeds of 200-800 feet/second (60-250 m/s) in shot blasting. The impact on the workpiece surface produces the desired cleaning, peening or texturing effect.

Applicable processes include:

- Surface cleaning to remove debris and descale after forging, casting or heat treatment. This often produces a rougher surface.

- Peening to create more resistance against general wear and corrosion stress cracking through compressive stress.

- Cosmetic blasting/texturing to produce a very fine, matte, anti-glare finish and improve an instrument’s aesthetics.

- Surface preparation prior to coating to create better adhesion of the coating material.

Medical applications mainly use air blast systems. To meet stringent hygiene requirements, however, Rosler’s wet blasting systems can be used to blend machining lines and create a very smooth, non-glare finish.

In a wet blasting process, the blast media and water slurry are propelled through the blast nozzle by compressed air and can be precisely directed at the parts. Use of this technique is often a secondary step after mass finishing and a KeramoFinish® polishing process to achieve the necessary surface smoothness for cleaning and sterilization.

Generally, shot blasting makes a surface rougher. The smoothest finishes achieved with shot blasting are about Ra = 16-32 micro inches (0.4-0.8 µm).

The Rosler Way

From choosing the right material to attaining the required surface finish and meeting rigorous specifications, processing medical instruments requires insight and expertise. Rosler offers a series of guidebooks to illustrate all of the considerations when selecting a surface finishing partner and process in the medical device industry.

You can download your copy of Rosler’s guidebooks today:

- Medical Instruments Guidebook

- Spinal Surgery Implants Guidebook

- Trauma Implants Guidebook

- Orthopedic Implants Guidebook

The Rosler Blog also offers tips and insight from the world’s leader in surface finishing. There you can search for topics of interest to you or sign up for enews alerts.

Contact us to discuss your challenges and our capabilities within the medical industry.

About the Author

Bernhard Kerschbaum is the CEO of Rosler Metal Finishing USA, part of the Rosler Group. With more than 80 years of surface finishing expertise, Rosler is uniquely capable of “Finding a better way…” as its motto states. For more information, visit our website or email.