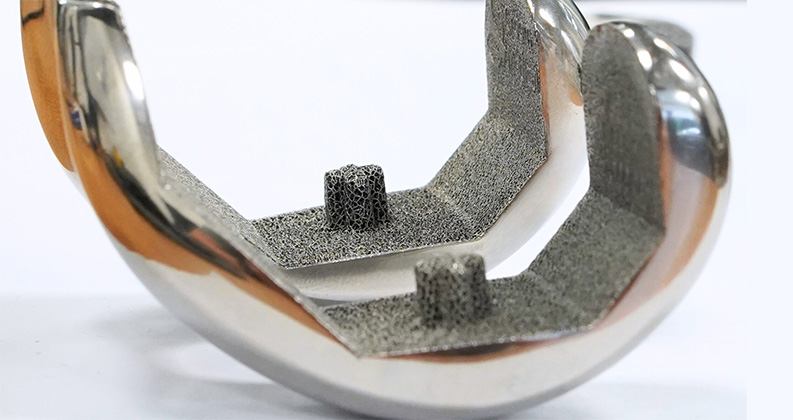

Amplify Additive of Scarborough, Maine added an EOS M290 DMLS Laser Powder Bed Fusion Platform to its current orthopedic printing capacity.

Amplify Additive offers both the EBM and laser platforms, and now employs the GE Additive Arcam Q10plus EBM platform and the EOS M290 DMLS platform to help orthopedic clients realize their additive orthopedic market solutions.

CEO and Founder Brian McLaughlin said, “The original vision for Amplify was to be technology-neutral with regards to leveraging additive manufacturing for the design and manufacturing of 3D-printed titanium orthopedic implants. While we are firm believers that EBM technology is undoubtedly the best technology for specific applications within the orthopedic market, to be a supplier who takes a solutions-based approach instead of a technology approach, it was inevitable that we would eventually have Laser Powder Bed Fusion here at Amplify.”

McLaughlin adds: “Teams often have a shared vision, but uncertainty about how best to implement additive manufacturing. This can sometimes present hurdles to overcome. We’re able to use our expertise on both sides of the aisle, both clinical and engineering, to add value and offer organizations a solution to overcome those hurdles. We implicitly understand both sides of the conversation. The orthopedic community is a beacon for using additive manufacturing to drive innovation, from the concept stage to the volume production of implants. Continued education about our process of Additive Manufacturing with EBM and Laser will only empower surgeons and engineers to push boundaries further in improving patient outcomes.”

Amplify Additive manufactures orthopedic implants for improved patient outcomes.

Source: Amplify Additive

JAV

Julie A. Vetalice is ORTHOWORLD's Editorial Assistant. She has covered the orthopedic industry for over 20 years, having joined the company in 1999.