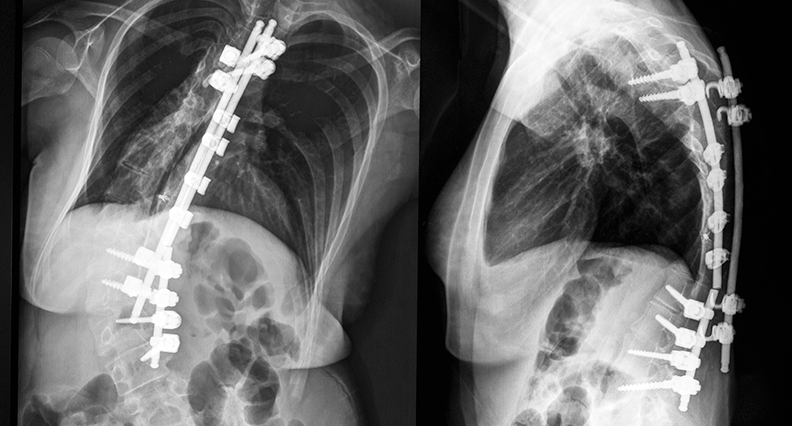

Pedicle screws, fusion rods and spinal fusion cages are an example of spinal implants requiring surface finishing.

With worldwide sales at nearly $10 billion annually, there is a high demand for spinal implants. These implants are subject to very specific and strict surface finishing requirements to ensure longevity and fixation to bone.

Mass finishing and shot blasting play key roles in creating the right finish for spinal implants, not only for intermediate surface treatment after forging, casting, machining, additive manufacturing, etc., but also for placing the final surface finish before implantation.

Let’s examine the capabilities of mass finishing and shot blasting for spinal implants and ways that Rosler can develop a precise and repeatable finishing process to meet your unique challenges and goals.

Mass Finishing

As a universal finishing technology that can be used for a multitude of surface treatment operations, mass finishing is ideal for spinal implants as well as instruments used for spinal surgery.

Applicable processes include deburring/edge radiusing, surface cleaning/de-oiling, as well as descaling after casting, forging, blanking, machining, heat treatment, thread rolling for screws, and additive manufacturing.

Mass finishing is equally suitable for surface smoothing and high gloss polishing down to Ra = 0.8 micro inches.

For very critical instruments, mass finishing is a preparatory step for electro-polishing.

Rosler Mass Finishing FKS Centrifugal Disk Finisher

Typical mass finishing machines for treating spinal implants include:

- Small rotary and tub vibrators – These machines provide great results for interbody fusion cages, artificial discs, cervical plates, spinal rods and surgical instruments.

- Small centrifugal disc finishers – Offering high-energy systems 10 times more intensive with vibratory finishers, these machines are great for pedicle screws, spinal hooks, cervical plates and artificial discs.

- Compact drag finishers – Perfect for finishing delicate surgical instruments and workpieces, these machines feature very high processing intensity, larger work piece capabilities, no part-on-part impingement and extremely smooth polished finishes.

Shot Blasting

Shot blasting is an exceptionally versatile surface treatment technology that is used for deburring/de-flashing, surface cleaning (de-scaling, rust removal, and stripping of coatings, surface preparation for coating, for cosmetic purposes and even surface improvement.

In connection with spinal implants, shot blasting is primarily used for surface cleaning, surface preparation for coatings, preliminary smoothing of additive manufactured components and shot peening.

Shot blasting is also used for cosmetic purposes such as placing a very fine, matte anti-glare finish on certain surgical instruments. These finishes aid in usability as well as cleanliness.

To meet stringent hygiene requirements, Rosler’s wet blasting systems are used to blend machining lines and create a very smooth, non-glare finish. In a wet blasting process the blast media and water slurry is propelled through the blast nozzle by compressed air and can be precisely directed at the parts.

Wet blasting in action

Use of this technique is often a secondary step after mass finishing and a KeramoFinish® polishing process to achieve the necessary surface smoothness for cleaning and sterilization.

Typical shot blasting machines for treating spinal implants include air and wet blast cabinets. Customized with rotary baskets, turntables, and rotary satellite stations, these machines offer blast cleaning and deburring for screws, cervical plates, interbody fusion cages and more.

Rosler wet blasting machine

The Rosler Way

Regardless of your spinal implant processing needs, Rosler can develop and deliver a better way to achieve precise finishing results. Learn more about surface finishing capabilities for spinal implants in our Spinal Surgery Implants Guidebook and contact us today to discuss your unique challenges.

About the Author

Bernhard Kerschbaum is the CEO of Rosler Metal Finishing USA, part of the Rosler Group. With more than 80 years of surface finishing expertise, Rosler is uniquely capable of “Finding a better way…” as its motto states. For more information, visit www.us.rosler.com or email rosler-us@rosler.com.