-

Xact Wire EDM Corp

N8 W22399 Johnson Dr

Waukesha, WI

53186

United States - 30,000 sq. ft., 2 facilities

- 262-549-9005

- 70+ employees

- Founded in 1984

- Operating in North America

- Visit Website

Business Development

QA Manager

Division Manager – IL Facility

Changes saved

- Component Parts

- Instruments

- Manufacturing

Xact Wire EDM Corp. is a leading nationwide provider of premier wire EDM, small hole EDM machining & laser part marking services. Medical projects have included femoral, tibial, resection cut blocks, endoscopic components, laparoscopic graspers & forceps, bone plates and other medical components. Two fully equipped locations to provide you with the very best service. Both locations are ISO 9001:2015 Certified.

XACT Wire EDM is a premier wire-cut EDM outsource supplier and provider of wire EDM services. Our team partners with a broad cross section of industries to supply high-precision prototypes, medium-volume runs, and long-term, high-volume EDM component production services.

Wire EDM Clients

We work with clients that have in-house EDM departments to supplement their existing capabilities, as well as with tool and die shops that do not have in-house wire EDM capabilities, and many other OEMs and contract manufacturers who do not have their own wire EDM equipment.

Wire EDM Machines

XACT Wire EDM has a pool of over 45 EDM machines available for production. We have made a point of consistently purchasing new programming, machines, and inspection equipment to ensure that we can offer the latest technology and the greatest precision, along with the highest throughput. The result is a broad production capability that allows us to match different part characteristics and volume requirements to the most appropriate pieces of equipment.

Wire EDM Services

XACT Wire EDM is a premier wire-cut EDM outsource supplier and provider of wire EDM services. Our team partners with a broad cross section of industries to supply high-precision prototypes, medium-volume runs, and long-term, high-volume EDM component production services.

Wire EDM Clients

We work with clients that have in-house EDM departments to supplement their existing capabilities, as well as with tool and die shops that do not have in-house wire EDM capabilities, and many other OEMs and contract manufacturers who do not have their own wire EDM equipment.

Wire EDM Machines

XACT Wire EDM has a pool of over 45 EDM machines available for production. We have made a point of consistently purchasing new programming, machines, and inspection equipment to ensure that we can offer the latest technology and the greatest precision, along with the highest throughput. The result is a broad production capability that allows us to match different part characteristics and volume requirements to the most appropriate pieces of equipment.

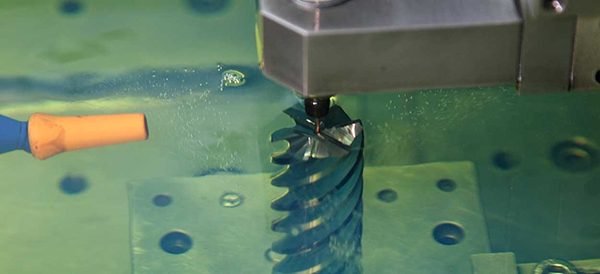

In small hole EDM, a small-diameter (usually hollow) spinning electrode is applied to a workpiece. Also known as EDM drilling, small hole EDM has traditionally been used to produce holes in fuel injectors, turbine blades, cutting tools (coolant holes), and more. XACT Wire EDM provides comprehensive small hole EDM services to a variety of industries nationwide. Learn more below, or contact us for a quote to get started.

- Electrode diameter from 0.010″ (.25mm) to 0.090″ (2.3mm)

- Finished hole sizes from .012-.015″ (.34mm) to .121-.126″ (3.14mm)

- Maximum thickness from 1/4 inch (6mm) to 9 inches (225mm)*

- *Up to 14: part height possible, depending on part configuration

- Maximum XY travel: X-22″ & Y-14″

- Other sizes may be available with lead time and/or large quantity orders.

Small Hole EDM

In small hole EDM, a small-diameter (usually hollow) spinning electrode is applied to a workpiece. Also known as EDM drilling, small hole EDM has traditionally been used to produce holes in fuel injectors, turbine blades, cutting tools (coolant holes), and more. XACT Wire EDM provides comprehensive small hole EDM services to a variety of industries nationwide. Learn more below, or contact us for a quote to get started.

- Electrode diameter from 0.010″ (.25mm) to 0.090″ (2.3mm)

- Finished hole sizes from .012-.015″ (.34mm) to .121-.126″ (3.14mm)

- Maximum thickness from 1/4 inch (6mm) to 9 inches (225mm)*

- *Up to 14: part height possible, depending on part configuration

- Maximum XY travel: X-22″ & Y-14″

- Other sizes may be available with lead time and/or large quantity orders.

Laser marking services is a term that covers a wide range of laser part marking processes. Because there are many different processes, it is possible to add markings to just about any material.

Industrial laser marking involves using a low-powered laser beam and moving it in a highly controlled path to create a desired set of alpha-numeric characters or a free-form pattern. This method of marking provides durable product identification that is becoming a more and more common requirement for many different categories of products. Most product identification is used as a traceability method for safety, inventory control, or other identification requirements related to regulatory mandates.

XACT Wire EDM’s laser marking services are commonly used to produce bar codes, QR codes, logos, and other identifying marks such as serial numbers or other regulatory information.

Laser Part Marking

Laser marking services is a term that covers a wide range of laser part marking processes. Because there are many different processes, it is possible to add markings to just about any material.

Industrial laser marking involves using a low-powered laser beam and moving it in a highly controlled path to create a desired set of alpha-numeric characters or a free-form pattern. This method of marking provides durable product identification that is becoming a more and more common requirement for many different categories of products. Most product identification is used as a traceability method for safety, inventory control, or other identification requirements related to regulatory mandates.

XACT Wire EDM’s laser marking services are commonly used to produce bar codes, QR codes, logos, and other identifying marks such as serial numbers or other regulatory information.

Waukesha, WI

United States

Unit 126

Cary, IL

United States