-

ENDO Manufacturing Co Ltd

987 Higashiota

Tsubame-shi, Niigata-ken

959-1289

Japan - 4 Facilities

- 81-256-63-8165

- 157+ employees

- Founded in 1950

- Operating in Asia

- Visit Website

Sales Executive

Changes saved

- Instruments

- Manufacturing

- Testing

ENDO Manufacturing is one of the most experienced contract manufacturers of forged orthopedic implants in Japan. We have been increasing our presence in the medical device field, utilizing precision forging technology that is the foundation of our long history of forging expertise. With exceptional quality, short lead times and the most competitive pricing in the industry, we have earned the trust of the world’s largest medical device manufacturers around the globe.

• Hip Stems

• Femoral Heads

• Femoral Cups

• Trauma Plates

• Tibial Trays

• Humeral Stems and Heads

• Instrumentation

• Femoral Components

Products

• Hip Stems

• Femoral Heads

• Femoral Cups

• Trauma Plates

• Tibial Trays

• Humeral Stems and Heads

• Instrumentation

• Femoral Components

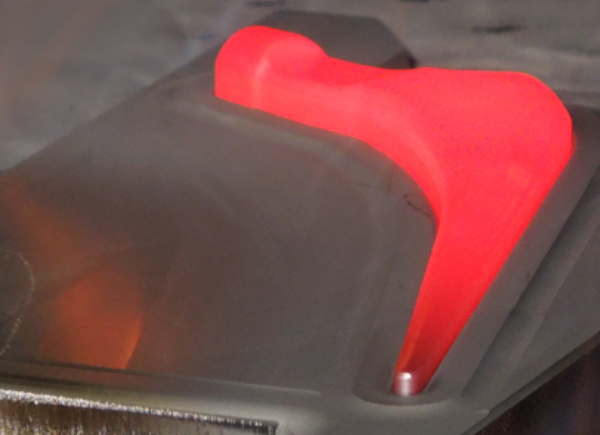

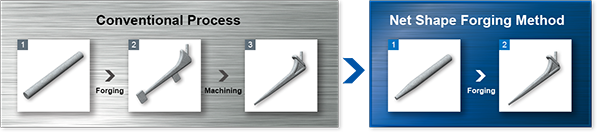

Endo Manufacturing’s core competency is precision forged products. Throughout our history, we have constantly refined our processes and built upon our long-standing tradition of manufacturing quality forgings at an extremely competitive price. By using our near net shape forging method, we can produce a product much closer to the dimensions of the finished product. As a result, this allows us to offer our customers a product with much less machining and a considerable raw material cost savings.

Net Shape Forging

Endo Manufacturing’s core competency is precision forged products. Throughout our history, we have constantly refined our processes and built upon our long-standing tradition of manufacturing quality forgings at an extremely competitive price. By using our near net shape forging method, we can produce a product much closer to the dimensions of the finished product. As a result, this allows us to offer our customers a product with much less machining and a considerable raw material cost savings.

Endo Manufacturing’s capabilities include 3D modeling, manufacturing of our own tooling in-house that significantly reduces our lead times, forging, machining, polishing and a rigorous final inspection process including FPI. By having all these capabilities in-house, we can reduce our customers’ lead times and offer extremely competitive pricing in the orthopedic market.

Integrated Manufacturing System

Endo Manufacturing’s capabilities include 3D modeling, manufacturing of our own tooling in-house that significantly reduces our lead times, forging, machining, polishing and a rigorous final inspection process including FPI. By having all these capabilities in-house, we can reduce our customers’ lead times and offer extremely competitive pricing in the orthopedic market.

Endo Manufacturing has aggressively sought opportunities throughout our history utilizing our technology and experiences to deliver outstanding quality and provide the best products available in the market. Endo Manufacturing is actively developing casting capabilities since 2020 to further support our customers’ needs. We started receiving orders and supplying of casted parts.

Unlimited Solutions

Endo Manufacturing has aggressively sought opportunities throughout our history utilizing our technology and experiences to deliver outstanding quality and provide the best products available in the market. Endo Manufacturing is actively developing casting capabilities since 2020 to further support our customers’ needs. We started receiving orders and supplying of casted parts.