-

Danco Medical

2450 Deelyn Dr

PO Box 2050

Warsaw, IN

46581

United States - 50,000 sq. ft. combined

- 574-269-5900

- Founded in 1971

- Operating in Asia, North America

- Visit Website

General Manager

Sales Manager

Changes saved

- Manufacturing

- Surface Preparation/Treatments

- Testing

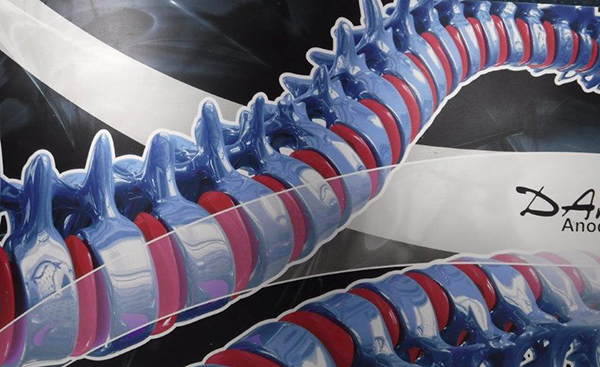

Headquartered in Warsaw, Indiana, USA, Danco Medical has been meeting the needs of medical device companies for technically superior surface preparation and finishing by providing titanium and aluminum anodizing of machined parts, implants, instruments, and devices, as well as electropolishing, passivation, LFC, and HAnano surface treatment. Danco Medical also offers marking capabilities of laser etch, deep image graphics, and epoxy ink. Danco Medical is NADCAP & ISO 13485 Certified.

Titanium (type-2 AMS 2488 & Titanium colors) and Aluminum Anodizing (type-II, type-III in clear and colors) from medical device parts to aerospace parts which are subject to abrasive wear, to brightly-colored consumer products, anodizing can economically add necessary operating characteristics and eye appeal. Both processes are RoHS compliant.

Anodizing

Titanium (type-2 AMS 2488 & Titanium colors) and Aluminum Anodizing (type-II, type-III in clear and colors) from medical device parts to aerospace parts which are subject to abrasive wear, to brightly-colored consumer products, anodizing can economically add necessary operating characteristics and eye appeal. Both processes are RoHS compliant.

Electropolishing and passivation of stainless steel helps to brighten and prevent rusting. Chemical Films (also known as Iridite, Alodine and Chromate Conversion coatings) on aluminum are conductive coatings that add corrosion resistance as well as provide a good paint base. All processes except type-I Chem Film are RoHS compliant. HAnano Surface Treatment also provided.

Specialized Treatments

Electropolishing and passivation of stainless steel helps to brighten and prevent rusting. Chemical Films (also known as Iridite, Alodine and Chromate Conversion coatings) on aluminum are conductive coatings that add corrosion resistance as well as provide a good paint base. All processes except type-I Chem Film are RoHS compliant. HAnano Surface Treatment also provided.

Laser marking is an ideal choice for such diverse products such as surgical plates, screws, nails, automotive castings, instrument bases and precision instrument dials. With Deep Image, colors ranging from subtle to bold can be aluminum anodized into a long-lasting wear-resistant product. Currently, this process is being used for Cases & Trays.

Precision Marking & Deep Image

Laser marking is an ideal choice for such diverse products such as surgical plates, screws, nails, automotive castings, instrument bases and precision instrument dials. With Deep Image, colors ranging from subtle to bold can be aluminum anodized into a long-lasting wear-resistant product. Currently, this process is being used for Cases & Trays.

(LFC) This hard chrome surface treatment process improves wear and abrasion resistance, reduces friction and galling and greatly improves the performance of stainless steel devices. In loaner programs, it will increase the life of an instrument by 30% to 45%. The LFC process is Biocompatible and RoHS compliant.

Chrome Coating

(LFC) This hard chrome surface treatment process improves wear and abrasion resistance, reduces friction and galling and greatly improves the performance of stainless steel devices. In loaner programs, it will increase the life of an instrument by 30% to 45%. The LFC process is Biocompatible and RoHS compliant.

- Manufacturing Cleaning Effectiveness

- Type 2 and Color Titanium Anodizing

- HAnano Coating

- Type II (Standard) and Type III (Hard) Aluminum Anodizing

- Chemical (Chromate) Conversion Coatings

- Nitric Passivation

- Citric Passivation

- Electropolish

- Low Friction Chrome Coating

- Laser Marking: Implants and Instruments

- Deep Image Graphics

- Epoxy Ink Marking

Validated Processes

- Manufacturing Cleaning Effectiveness

- Type 2 and Color Titanium Anodizing

- HAnano Coating

- Type II (Standard) and Type III (Hard) Aluminum Anodizing

- Chemical (Chromate) Conversion Coatings

- Nitric Passivation

- Citric Passivation

- Electropolish

- Low Friction Chrome Coating

- Laser Marking: Implants and Instruments

- Deep Image Graphics

- Epoxy Ink Marking

Warsaw, IN

United States

Xinbei District

Changzhou, Jiangsu / 江苏

China