Contract manufacturer OKAY Industries has opened NexTech Labs, prototyping and process development labs offering equipment, resources and staff who work collaboratively with customers to solve complex engineering design challenges for medical devices.

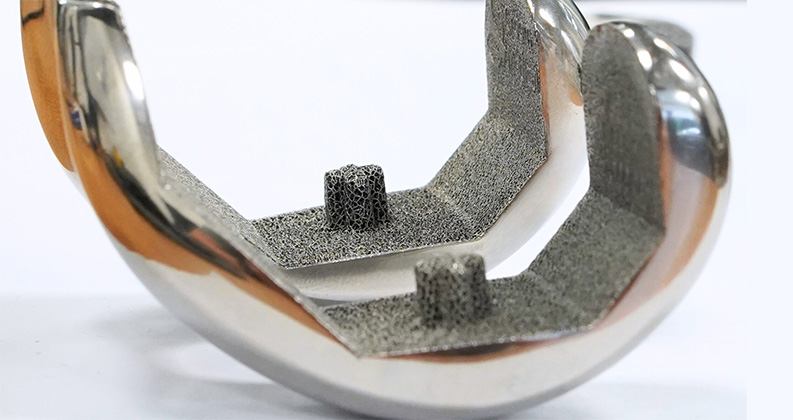

The centers offer multi-axis, high-speed CNC and LaserSwiss machining, laser tube cutting, laser welding, marking and surface treating, supported by integrated design software and advanced robotic technologies, as well as 3D printing for quick-turn feasibility testing, tooling and fixtures.

“NexTech Labs bring our resources and expertise to a space where we can directly collaborate with customers,” said Sean Stowik, Director of Sales and Marketing. “We can get products to market faster and solve issues early in the design stage, which ultimately lowers production costs and improves manufacturability. By working one-on-one with medical device OEMs early on, we create custom manufacturing solutions that deliver high-quality, reliable components and sub-assemblies with speed and cost-efficiency.”

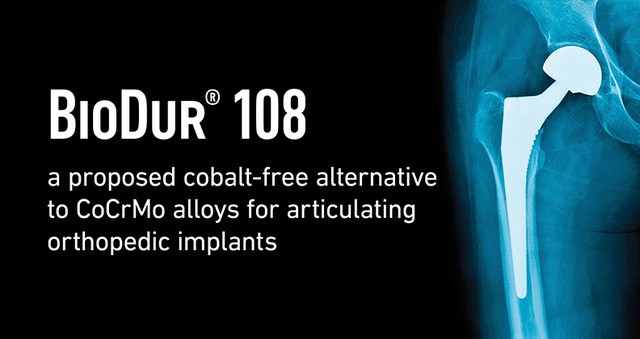

OKAY Industries supports orthopedic device companies that produce arthroscopic instrument components and assemblies; titanium and stainless steel staples; surgical cutters, blades/knives, scissors and assemblies; implantable orthopedic components, etc.