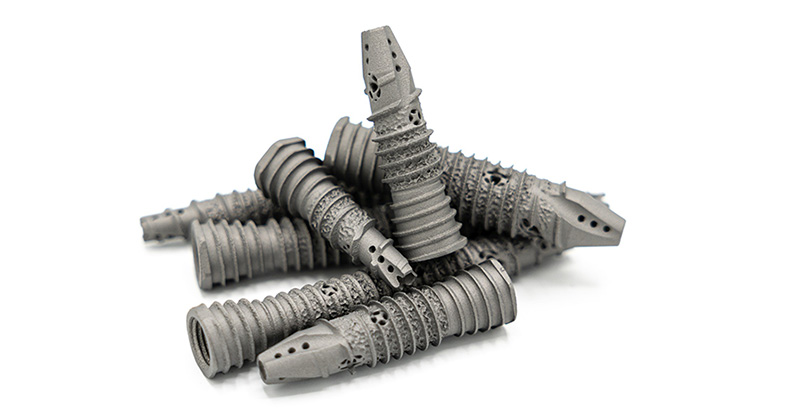

Amnovis, a contract manufacturer specializing in 3D-printed medical devices and high-performance applications, proudly marks its fifth anniversary with the shipment of its 100,000th 3D-printed implant. Founded in June 2020 by Peter Mercelis and Ruben Wauthle, Amnovis was built with a mission to deliver high-quality products, exceptional customer service, and reliable on-time delivery to demanding and regulated industries.

With a customer acceptance rate exceeding 99.9% and an on-time delivery rate above 90% for three consecutive years, Amnovis has become a trusted partner in the medical device industry. The milestone 100,000th implant was Promethean Restorative’s FDA-cleared SI fixation device, manufactured and delivered by Amnovis to support their product launch.

In 2025, the company expects to ship over 50,000 implants, half of its five-year total in just one year. To meet this demand, the company is expanding its production capacity for medical devices and other applications.

Over the past five years, Amnovis has developed and validated several innovations, some of which have already been transferred into production, while others are progressing through pilot and R&D phases:

- Heat Treatment–Free Titanium: Amnovis claims to be the only contract manufacturer to offer 3D-printed pure titanium that meets ASTM standards without requiring heat treatment. This validated material is employed in spine, CMF, and orthopedic applications.

- Deformable Implants: A patented concept enabling patient-specific implants by deforming highly porous regions of standardized components. This offers customization at the cost of standard manufacturing and is being co-developed with customers for market entry.

- Multi-Metal 3D printing: Currently in R&D, Amnovis is developing capabilities to print components using two or more metals via L-PBF, a promising step toward next-generation applications.

“From day one, we wanted Amnovis to be more than just another supplier,” said Ruben Wauthle, CEO and Co-founder. “We set out to build a company that consistently delivers high-quality parts, communicates transparently, and meets deadlines. Five years later, we’re proud to say we’re doing exactly that.”

“As we look ahead, we’re excited about the opportunities to scale our impact even further,” Wauthle concluded. “We’re building on a solid foundation of quality and reliability, and we’re committed to turning cutting-edge ideas into real-world solutions for our customers.”

Source: Amnovis

JAV

Julie A. Vetalice is ORTHOWORLD's Editorial Assistant. She has covered the orthopedic industry for over 20 years, having joined the company in 1999.