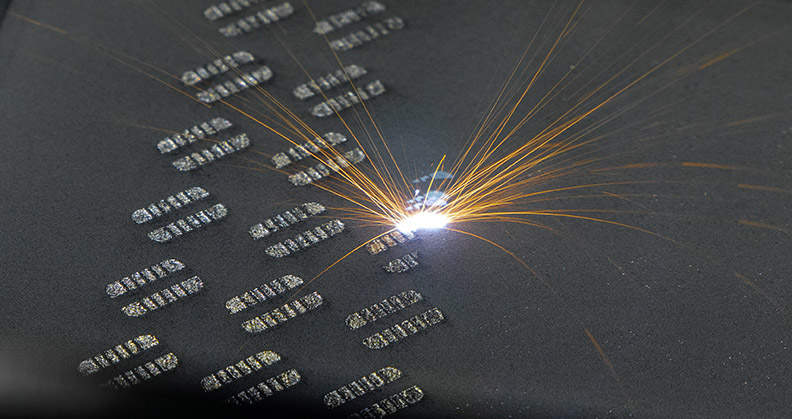

In additive manufacturing (AM), ensuring that parts meet high mechanical and quality standards is critical, especially in the medical device industry, where precision and reliability are non-negotiable. The promise of AM lies in its ability to create highly complex geometries, patient-specific implants and lightweight yet durable structures. However, post-processing technologies must ensure consistent mechanical strength, fatigue resistance and long-term durability to deliver on that promise.

Hot Isostatic Pressing (HIP) is one of the most important post-processing techniques in the AM workflow. By applying high temperature and pressure in a controlled environment, HIP eliminates internal porosity, densifies material and enhances mechanical performance. This step transforms printed parts into components that can withstand the demanding requirements of medical applications.

The Role of HIP in Additive Manufacturing

Additive processes, while powerful, often introduce internal porosity and shrinkage defects that can compromise performance. HIP addresses these issues by collapsing voids and increasing density, resulting in improved fatigue resistance, corrosion resistance and overall durability. For medical devices, where mechanical integrity directly impacts patient safety, HIP provides a critical safeguard.

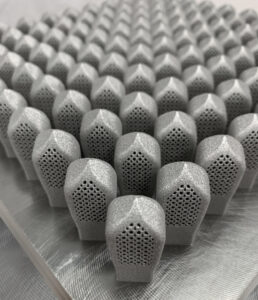

HIP is particularly valuable for complex or lattice-based geometries, where internal defects may be nearly impossible to identify or remove through other means. By improving material integrity at the microscopic level, HIP ensures that implants meet the stringent fatigue and performance standards set by regulators and expected by surgeons.

Recent advancements in HIP have further enhanced its role in AM. Capabilities such as argon gas quenching and in situ solution heat treatment (SHT) allow HIP to simultaneously densify and heat treat, thereby optimizing the microstructure while minimizing distortion and improving the surface finish. These improvements reduce the need for additional processing and shorten overall production timelines.

Advanced HIP Technology at Paragon Medical

Despite its critical role, HIP has historically been a bottleneck for medical device companies. Traditional HIP providers serve multiple industries, and aerospace contracts often take precedence over medical devices. As a result, lead times of four to six weeks are common, which is incompatible with the growing need for rapid production of patient-specific implants. Costs can also rise quickly, with some providers charging by weight rather than by run, which encourages part removal from build plates before HIP and introduces dimensional variation.

Paragon Medical has eliminated these barriers by incorporating in-house HIP as part of its vertically integrated AM capabilities. As far as is known, Paragon is the only medical contract manufacturer with dedicated in-house HIP capability, providing unmatched supply chain control and efficiency.

At the core of this capability is the Quintus QIH 60 URC®, designed specifically for AM and fully validated for 3D-printed Ti6Al4V. This system integrates high-pressure heat treatment (HPHT™) to combine densification and heat treatment in one cycle, reducing overall process steps. The chamber accommodates full-size build plates (273mm x 273mm), enabling parts to be HIPed directly on the build plate without added handling or risk of distortion.

Key technical benefits include:

- Streamlined production. HPHT reduces lead time and simplifies workflow by combining densification and heat treatment.

- Reduced cost. HIP mitigates the formation of alpha case, lowering the need for expensive post-processing.

- Precision control. Variable speed fan technology and controlled ramp and cool rates ensure highly uniform outcomes.

- Gas quality monitoring. Inline gas chromatography detects contaminants or moisture that could compromise fatigue performance.

- Titanium-only processing. Dedicated HIP runs eliminate the risk of cross-contamination with other alloys.

Additionally, the Quintus PURUS® system minimizes oxidation and surface alpha case, resulting in consistently clean HIP runs and improved surface quality. Each run is verified for alpha case, providing further quality assurance.

In-house HIP is part of Paragon Medical’s fully integrated additive manufacturing solution.

Driving Excellence in Medical Manufacturing

Integrating HIP in-house is not simply about shortening one step of the production process. It is about creating total process control from design through commercialization. By offering HIP as part of a vertically integrated AM ecosystem, alongside design support, printing, machining and finishing, Paragon Medical ensures that every stage of manufacturing is optimized for speed, consistency and reliability.

For OEMs, this translates into:

- Reduced lead times compared to outsourced HIP, especially critical for patient-specific implants.

- Lower costs and reduced development delays by eliminating unnecessary handling or premature part removal.

- Consistent, contamination-free processing dedicated to titanium implants.

- Greater confidence in mechanical properties, fatigue performance and overall reliability.

As the medical device industry embraces patient-specific implants and more complex AM designs, traditional HIP outsourcing will not meet the need for rapid turnaround. Paragon Medical’s investment in HIP represents both a technological advancement and a commitment to enabling faster, more reliable commercialization of next-generation medical devices.

Additive manufacturing reduces lead time, cost and supply chain complexity.

The Partner of Choice for Additive Manufacturing

HIP is only one part of the complete AM solution at Paragon Medical. By bringing critical steps in-house and aligning with trusted technology partners like Quintus, Paragon simplifies the supply chain and reduces risk for OEMs. The result is an integrated pathway from concept to finished implant that delivers speed, precision and confidence.

For medical device companies, the value lies in more than a single processing step. It lies in a partner with the capabilities, expertise and commitment to manage the entire AM journey. Paragon Medical is uniquely positioned to deliver on that promise, making it the partner of choice for AM in the medical device industry.