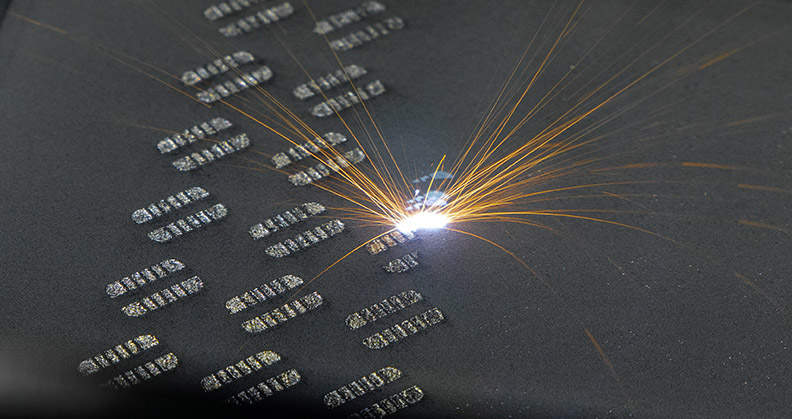

Norman Noble has established a dedicated manufacturing cell to accelerate the development of orthopedic prototypes within its Process Development Centers (PDCs). The new cell is equipped with a Tsugami mill, advanced finishing systems, and enhanced inspection tools, including AI-driven process monitoring, to deliver complex orthopedic prototypes faster than ever.

The dedicated manufacturing cell strengthens Norman Noble’s core capabilities in microprecision medtech manufacturing and finishing, enabling engineers and developers to iterate designs quickly and move seamlessly from prototype to production. With integrated inspection systems and AI-based monitoring, the new cell ensures tight tolerances, repeatability, and consistent quality for even the most demanding applications.

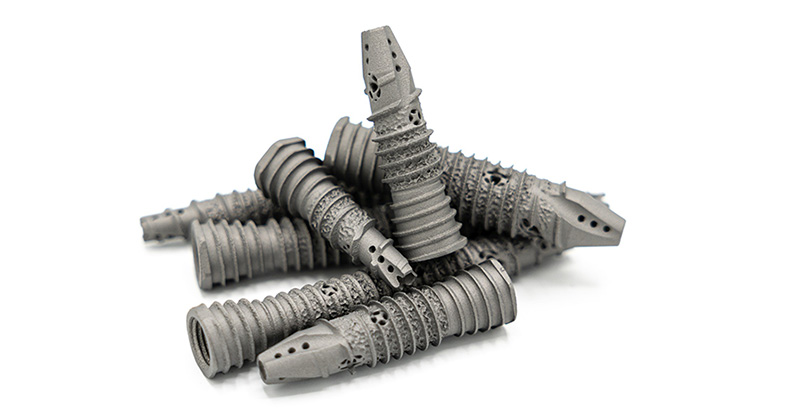

Norman Noble PDCs support customers with ultra-precision micromachining of medical devices from initial prototype through all stages of FDA approval to full-scale manufacturing. The company’s PDCs are central to helping medtech companies bring next-generation devices to market efficiently and cost-effectively, while meeting quality, delivery, and regulatory requirements.

“Our goal is to remove bottlenecks and streamline the prototype development steps to enable them to be completed within a few days,” said Dan Stefano, CEO of Norman Noble. “By dedicating a manufacturing cell to orthopedic prototypes, we’re helping customers accelerate iterations and bring innovative medical devices to market faster.”

Source: Norman Noble

JAV

Julie A. Vetalice is ORTHOWORLD's Editorial Assistant. She has covered the orthopedic industry for over 20 years, having joined the company in 1999.