The adoption of additive manufacturing continues to increase as orthopedic companies learn that the benefits of 3D printing extend far beyond innovative implant designs. The technology offers cost-effective advantages in product development, design cycles, inventory management and low-volume production.

“It’s a misunderstood capability. People often see it as expensive and difficult to implement, but once you get the right team members and processes in place, it begins to make sense,” said Sean McConnell, Engineering and New Product Introduction Manager at Croom Medical.

Measuring ROI

The front-end investment in additive manufacturing is quickly offset by downstream savings in time, inventory and market opportunity, according to Nick Cordaro, President of SpiTrex 3D. “We measure ROI by total program efficiency, including shorter development timelines, fewer design iterations and reduced tooling costs,” he said.

Partnering with a contract manufacturer that specializes in additive manufacturing allows OEMs to tap into the technology’s benefits without bearing the total risk of introducing a new capability. Still, companies must carefully evaluate which parts are best suited to be produced with 3D printing.

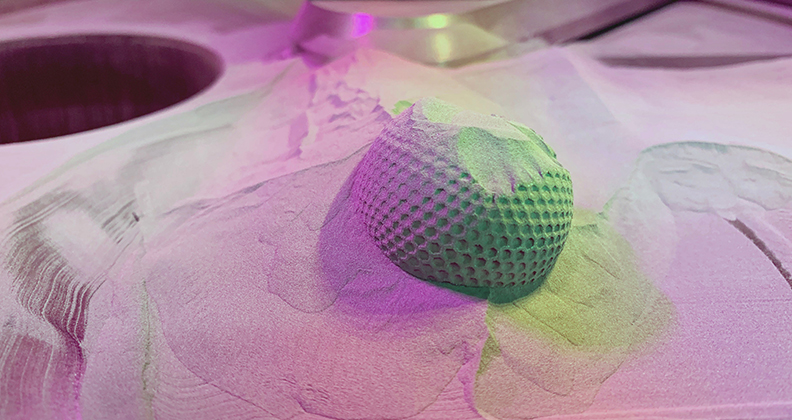

For example, the ability to create porous and lattice structures in the same device allows for bone ingrowth and better long-term stability. “That’s a game-changer,” said Ruben Wauthle, Ph.D., CEO of Amnovis.

According to Dr. Wauthle, the long-term implant performance advantages add to the cost benefits of additive manufacturing, even in cases where parts may be cheaper to produce through traditional subtractive manufacturing.

“You need to look at the technology’s total benefits,” he said. “If you can make a product with a porous structure that you cannot make with conventional machining, and patient outcomes are improved, then the cost efficiency is even better.”

Saving Time

Additive manufacturing accelerates R&D and shortens design cycles, speeding both prototyping and production.

“You can do quick design iterations during the prototyping phase,” Dr. Wauthle said. “Every week that you shave off during development saves time and cost, making the overall process more efficient.”

McConnell noted that consolidating multiple processes into printing runs can cut production time dramatically. For example, a shoulder implant that might take a month to machine can be 3D-printed in just days.

Cordaro offers a similar example involving a spinal implant that SpiTrex recently made for a customer. The company used additive manufacturing to iterate through five design revisions in under three weeks instead of the three to four months it would have taken with subtractive manufacturing.

Minimizing Materials

Unlike traditional subtractive manufacturing, which requires large inventories of rods, bars and tooling, additive manufacturing requires fewer material resources.

“We only need titanium powder, argon and electricity,” Cordaro said.

Dr. Wauthle agreed: “We stock one type of raw material — grade 23 titanium powder — and we can make whatever we want with it.”

Though titanium powder is more expensive per unit than rods or billets, the simplified supply chain, reduced tooling and lower setup requirements offset the difference.

Some post-processing is often required, but careful design for additive manufacturing can minimize the costs involved. Cordaro noted that 90% of SpiTrex’s printed parts require little more than basic finishing, like deburring or thread tapping.

“Engaging with additive manufacturing specialists early in the design phase is very important to optimize parts for printing while fulfilling the purpose of the implant,” said Marc Dietlin, Sales Manager at Amnovis.

Personalizing Solutions

The minimal tooling and simple material requirements of additive manufacturing, paired with its rapid prototyping capabilities, make the technology ideal for producing patient-specific implants and other personalized parts.

“Because we print to demand, customers can reduce their inventory carrying costs,” Cordaro said. “Rather than stockpiling SKUs, they order based on just-in-time inventory, which cuts back on overstocking and expiration risk.”

Dr. Wauthle emphasized the importance of short lead times in personalized implants.

“Since additive manufacturing doesn’t need complex tooling, we are perfectly positioned to respond to niche clinical needs,” he said. “We are as fast and flexible for new applications as we are for something we’ve produced multiple times before.”

Additive manufacturing also allows multiple low-volume product runs to be combined into a single build — hip cups, spinal cages, and SI joint implants, for example — at costs unachievable through machining.

“Depending on the size and geometry, additive manufacturing is more cost-effective for runs involving less than 200 parts,” Cordaro said.

Competitive Edge

Additive manufacturing has been a pivotal tool in Croom Medical’s transition from a reactive contract manufacturer to a proactive innovator, offering new technologies and solutions to optimize existing products and engineer new assemblies that weren’t possible with machining.

Amnovis is also exploring novel applications, such as deformable implants with oversized porous structures that surgeons can reshape during surgery. “It’s a patient-specific implant manufactured at the cost of a standardized component,” Dr. Wauthle explained. “That’s only possible thanks to the capabilities of additive manufacturing.”

As process controls improve and costs fall, additive manufacturing’s value proposition will only strengthen.

McConnell said companies that are willing to take risks and experiment with additive manufacturing and add it as a routine process will be the ones to unlock its advantages.

“The mentality shift can be difficult,” he added, “but these are the decisions you need to make in order to not be outpaced by the competition.”

Learn more about additive manufacturing’s cost- and time-saving advantages in the full-length version of this article.

BB

Brooke Bilyj is a contributing writer.