As additive manufacturing (AM) technologies and processes mature, orthopedic companies are realizing that the value of 3D printing transcends just innovation. When harnessed to its full potential, AM is a cost-effective product development tool that shortens design cycles, minimizes tooling expenses, simplifies inventory management and enhances low-volume production runs.

“It’s a misunderstood technology. People often see it as expensive and difficult to implement, but once you get the right team members and processes in place, it begins to make sense,” said Sean McConnell, Engineering and New Product Introduction Manager at Croom Medical. “Some parts can be far cheaper and quicker to print than to machine.”

By examining the advantages and ideal applications of AM compared to conventional production methods, orthopedic companies can capitalize on these tools to accelerate R&D while controlling costs and sharpening their competitive edge.

Measuring the ROI

Although the upfront investment in AM equipment and specialists can seem daunting, like any technology, the returns accrue over time.

“The front-end investment is quickly offset by downstream savings in time, inventory and market opportunity,” says Nick Cordaro, President of SpiTrex 3D, the AM division of SpiTrex Orthopedics. “We measure ROI by total program efficiency, including shorter development timelines, fewer design iterations, reduced tooling costs and faster regulatory clearance.”

Compared to the investment in a conventional mill-turn cell with an easily projected output of implants, the cost of an unfamiliar 3D metal printer seems like a more expensive risk, especially if you don’t have a defined plan, McConnell said.

Partnering with a contract manufacturer that specializes in AM allows OEMs to tap into the benefits without bearing the total risk. However, companies still need to understand the best use cases for AM before choosing the manufacturing process.

That’s because the advantages of AM greatly depend on the parts being produced, according to Cordaro. For example, a CNC machine may be more cost-effective for manufacturing large batches of simple parts, such as turning a thousand bone screws on a Swiss lathe.

“But where 3D printing gets especially cost-effective,” he said, “is complex geometries that are either impossible or cost-prohibitive to produce using traditional machining.”

The more complex the geometries or surface treatments need to be, the more advantageous AM becomes.

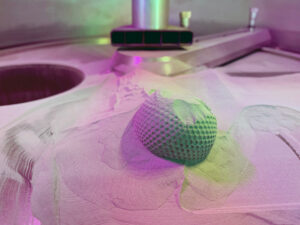

“For example, if you want a porous implant with traditional manufacturing, you need to send a machined part for plasma coating, which adds cost and time,” said Marc Dietlin, Sales Manager at Amnovis. “But with AM, you can print the solid and porous components at one time, which is very beneficial.”

This textural flexibility is one of the biggest benefits of AM. “You can make porous structures and lattice structures that allow for bone ingrowth and better long-term stability,” said Ruben Wauthle, Ph.D., CEO of Amnovis, which uses laser powder bed fusion (LPBF) to produce titanium spinal cages and other orthopedic implants. “That’s a game-changer.”

In fact, Dr. Wauthle said these long-term advantages outweigh the cost benefits of AM, even in cases where parts may be cheaper to produce through traditional subtractive manufacturing.

“You need to look at the total benefits like better implant performance,” he said. “If you can make a product with a porous structure that you cannot make with conventional machining and the outcome is much improved, then the overall cost efficiency is even better.”

Saving Time

A great deal of AM’s cost efficiency stems from its ability to shorten the design cycle, from rapid prototyping all the way through production.

“One of the benefits of AM is that you can do quick design iterations during the prototyping phase,” Dr. Wauthle said. “Every week that you shave off during development saves time and cost, making the overall process more efficient.”

But that’s just the first step. “Even more important is the cost-effectiveness during volume production of implants,” he noted. “That’s the most added value because it’s the longest phase of the product lifetime.”

The process consolidation enabled by AM is key to its time- and cost-saving potential. “The more I can do inside the printer, the more features I can add to the surface, the better,” McConnell said.

For example, Croom recently worked with an OEM to reissue implants that were originally cast, machined and plasma coated — which involved three external partners, adding extra time and costs to production.

Considering the complexities of the supply chain and the part geometries, Croom Medical’s engineers realized it was more effective to 3D print, consolidating three processes into one while keeping it at a comparable cost.

McConnell shared another example of a shoulder implant that Croom can 3D print using LPBF in about a quarter of the time it might take to machine.

“If I get the order on a Monday, I can start printing that evening and have the parts done by midweek, depending on the post-processing,” he said. “If I was to machine it from wrought, I’d need to come up with multiple setups, jigs and fixtures, ensure that I have the right size stock and tool lists, confirm there’s capacity on the machine, then create the CAD/CAM, verify the setup and get the parts out. It would take at least a month to get there.”

Cordaro offers a similar example of a spinal implant that SpiTrex recently made for a customer using AM to iterate through five design revisions in under three weeks instead of three to four months and significantly more expense using subtractive manufacturing.

Plus, these reduced development cycles usher products into verification and validation phases sooner, ultimately speeding up FDA submission timelines to bring products to market faster.

The raw materials needed for additive manufacturing allow for a straightforward inventory strategy.

Minimizing Materials and Post-Processing

When Cordaro visits other SpiTrex sister sites around the globe, which offer precision subtractive machining and compression molding of orthopedic products, he’s astounded by the massive material cages storing various metal rods, bar stocks and cannulations. “In the additive world, we only need titanium powder, argon and electricity,” he said.

The relative simplicity of raw materials required for AM presents another advantage. “It’s a very simplified, straightforward inventory strategy,” Dr. Wauthle said. “We only have one type of raw material — grade 23 titanium powder — and we can make whatever we want with it.”

Although titanium powder is more expensive than blank bars or rods, there are other benefits to sourcing a single material. “The powder is always the same size and specification,” McConnell said. “Mill-turns, grinding machines or Swiss lathes require a specific size of billet, which means we have to hold stock of certain sizes, some of which can have long lead times up to a year.”

Not only do subtractive machines require specific materials, but also specialized tooling tailored to each part.

“The setup costs for machining can be extremely onerous, because every part will likely need its own jig and fixture,” McConnell said.

These tooling costs are drastically reduced with AM, because the same 3D printer can produce any size, shape or geometry specified for a part. The catch, Dr. Wauthle said, is the need for post-processing.

“We always look at combining the best of both worlds,” he added. “So, for certain parts, we combine 3D printing with CNC milling or laser marking, and for those processes, you do need some tooling and custom fixtures.”

However, these post-processing steps and added costs can be minimized — and even eliminated — by strategically designing parts for AM. For example, Cordaro said that 90% of the parts SpiTrex 3D prints don’t require micro-machining or molding, aside from deburring, thread tapping or reaming.

Designing for AM (DfAM) demands a shift in mindset to optimize the nuances of this technology compared to subtractive mills or lathes. “It requires thinking about how a part is created in the printer,” Cordaro said.

Collaborating with a knowledgeable contract manufacturer to apply DfAM principles upfront can be critical to not only reducing costs, but leveraging the capabilities of AM. “Engaging with AM specialists early in the design phase is very important to make parts more AM-friendly while fulfilling the purpose of the implant,” Dietlin said.

Personalizing Solutions

The minimal tooling and simple material requirements of AM, paired with its rapid prototyping capabilities, make the technology ideal for producing patient-specific implants and other personalized parts.

“Because we print to demand, customers can reduce their inventory carrying costs. Rather than stockpiling SKUs, they order just-in-time inventory — cutting back on excess and expiration risk,” Cordaro said. “Those things aren’t really possible on the subtractive side; and if they are, they’re very expensive and time-consuming.”

Short lead times are critical for patient-specific implants, Dr. Wauthle noted, and AM delivers by enabling customized production within days, not weeks. “Since AM doesn’t need complex tooling, we are perfectly positioned to respond to niche clinical needs,” he said. “We are as fast and flexible for new applications as we are for something we’ve done multiple times before.”

Dr. Wauthle highlighted another advantage of AM in enabling multiple low-volume batches to be combined into one print run: producing small quantities of hip cups, spinal cages and SI joint implants with one build that could cover a whole year’s inventory for an OEM.

Tooling costs would make these small batches significantly more expensive to machine with traditional techniques. Although combining low-batch quantities into one run requires some additional setup costs compared to printing a full plate of identical parts, Dr. Wauthle said it’s still quicker and more cost-efficient than conventional manufacturing.

While the cost structures of subtractive machines might make more sense for higher volume runs producing thousands of parts, AM proves its efficiency with low-volume runs.

“Depending on the size and geometry, AM is more cost-effective under 200 parts because the setup, tooling and raw material needs are so much lower,” Cordaro said. “But we have builds that run 380 SI screws every 18 to 30 hours, and then we flip them in an hour or two, and we’re off building the next set.”

Gaining a Competitive Edge

AM has been a pivotal tool in Croom Medical’s transition from a reactive contract manufacturer to a proactive innovator, offering new technologies and solutions to optimize existing products and engineer new assemblies that weren’t possible with traditional machining.

For example, one customer came to Croom with an assembly that was proving difficult for surgeons to use. They envisioned a snap fit living hinge to connect two rigid sections of the implant.

“That’s very difficult, if not impossible, to do from a machining perspective, so we looked at it from a printing perspective that allowed us to completely change the locking mechanism,” McConnell said.

These cutting-edge technologies open the door to new innovations, such as the deformable implants patented by Amnovis. The parts are printed with an oversized porous structure on the bone contact surface, allowing the titanium to be reshaped or hammered into place during surgery to match the patient’s anatomy.

“It’s a patient-specific implant manufactured at the cost of a standardized component,” Dr. Wauthle explained. “That’s only possible thanks to the capabilities of AM. If you combine the complexities of the manufacturing method, design and material, you can get revolutionary applications.”

Meanwhile, as the process controls and understanding of AM technologies advance, the costs will continue to decrease, Cordaro predicted, making 3D printing an even more lucrative option for orthopedic innovation.

McConnell said companies that are willing to take risks and experiment with AM will be the ones to unlock these advantages by embracing 3D printing as a routine process. “The mentality shift was harder than we thought it would be,” he added, “but these are the decisions you need to make in order to not be outpaced by your competitors.”

BB

Brooke Bilyj is a contributing writer.