Ambulatory surgery centers (ASCs) continue to capture bigger percentages of joint replacement cases, thanks to advancements in minimally invasive surgical techniques and growing interest in value-based care that prioritizes efficiency and quality patient outcomes.

The market trends are eye-opening. Joint replacement is the largest segment in orthopedics by revenue, accounting for 36% of the $62 billion global market by ORTHOWORLD estimates. The 2024 American Joint Replacement Registry said that 62,110 joint replacements were performed in ASCs in 2023, 70% more than the previous year. According to CMS, over 25% of Medicare-approved total knee replacements were performed in ASCs in 2023. The American Academy of Orthopaedic Surgeons reports that 51% of hip replacements will be performed as outpatient procedures by 2026.

It’s no wonder that orthopedic companies are prioritizing technologies and products that put them in position to capture a sliver of the same-day surgery business. The development of compact surgical robots, handheld navigational tools and streamlined instrument sets are at the forefront of those efforts.

These innovations reduce sterile processing burdens, improve operating room turnovers and deliver the clinical precision needed to achieve the excellent outcomes expected by today’s younger and more demanding joint replacement patients.

“Flexibility is key for ASCs,” said Nic Aldrich, Vice President of Marketing at OrthAlign. “Today’s technology needs to help surgeons deliver high-quality patient care while meeting the unique needs of the outpatient environment.”

Handheld Options

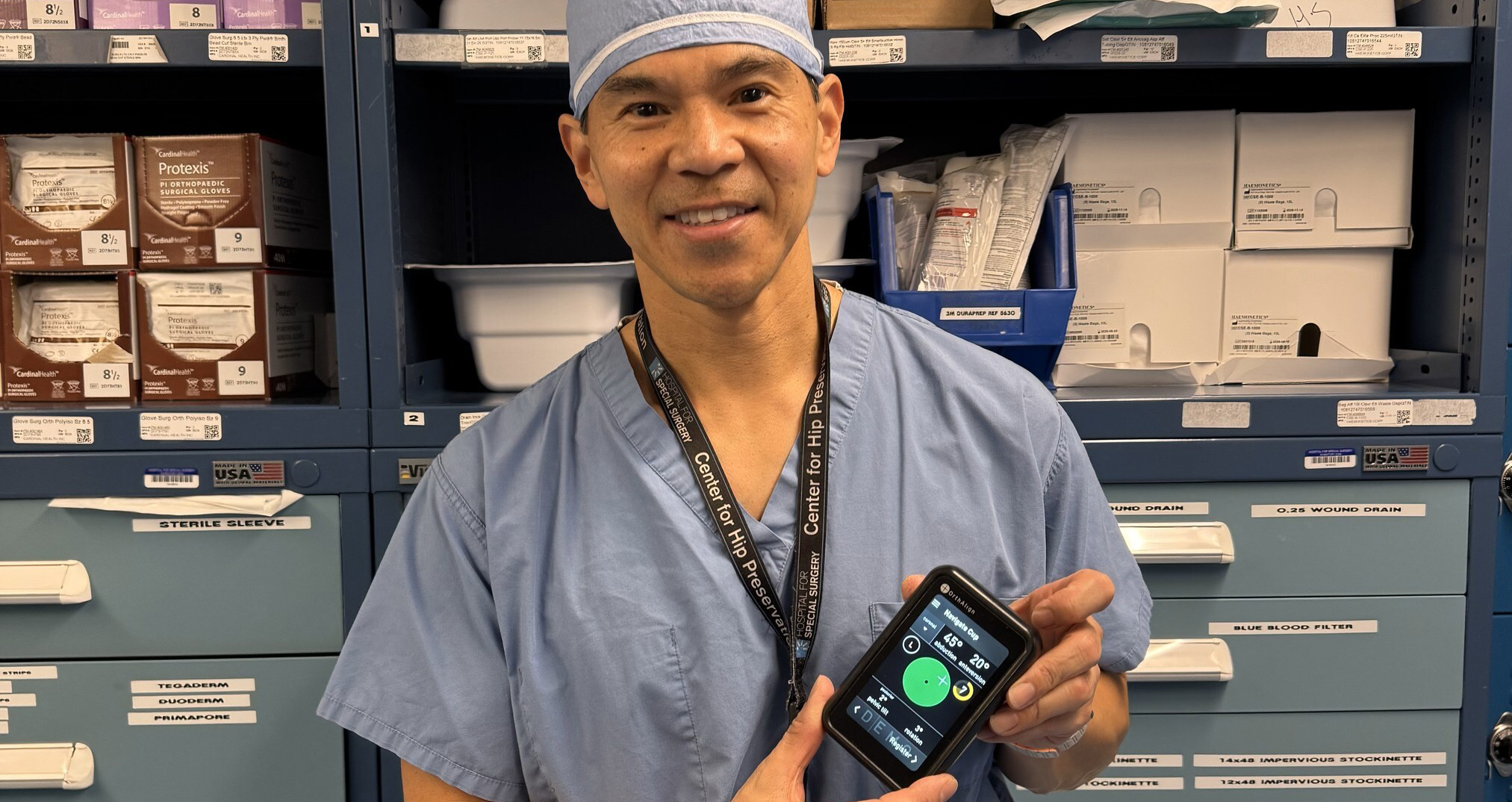

OrthAlign’s Lantern Hip navigation technology received FDA 510(k) clearance for direct anterior total hip arthroplasty performed with the patient in the supine position. Lantern Hip is the latest addition to the company’s Lantern platform, joining existing applications for total, revision and partial knee arthroplasty.

According to Aldrich, Lantern reflects the company’s mission to increase the accessibility of empowering technologies. The portfolio, which is designed to enhance flexibility and efficiency in ASCs, offers surgeons cutting-edge tools to perform personalized joint surgery.

For example, Lantern Hip facilitates precise acetabular cup placement during total hip procedures. It supports surgeons as they perform direct anterior hip replacement, allowing them to navigate cup placement in three planes: anterior pelvic, functional pelvic and sagittal or coronal. “Surgeons can account for spinal/pelvic mobility and align the cup based on the patient’s unique anatomy in a functional, dynamic way,” Aldrich said.

One of Lantern Hip’s useful features is its ability to align acetabular cup placement with the patient’s functional pelvic plane by taking into account how the pelvis moves during daily activities. This personalized approach helps prevent complications such as impingement and improves long-term patient satisfaction.

“We’re empowering surgeons to execute patient-specific plans with precision, all while maintaining simplicity and efficiency in their workflows,” Aldrich said.

Unlike traditional robotic systems, the handheld Lantern Hip operates entirely within the sterile field. Powered by inertial motion sensors, accelerometers and gyroscopes, the device eliminates the need for preoperative imaging or external tracking systems. Quick intraoperative registration maps a patient’s anatomy in real time, delivering precision in a compact package.

“We like to say Lantern Hip requires shelf space, not a parking spot,” Aldrich said, emphasizing its small size and ease of integration into ASCs compared to the large footprints of robotic systems.

Lantern systems are open platforms that are compatible with any implant brand, making them cost-effective options for ASCs that host multiple surgeons with various equipment preferences. The handheld devices also fit seamlessly into standard surgical workflows and require no additional equipment or capital investments.

“The entire Lantern platform is driven by that belief that every patient deserves exceptional surgical care,” Aldrich said. “We focus on accessibility, ensuring that these tools are easy to adopt and are adaptable to any site of service.”

To that end, the Lantern systems eliminate many barriers associated with traditional robotics, such as steep learning curves, high costs and rigid hardware requirements.

Advanced robotics like THINK Surgical’s TMINI Robot are also transforming the outpatient surgery landscape. TMINI, which weighs only seven pounds, is a handheld solution that’s tailored to the unique needs of ASCs.

In January, the company announced that the TMINI has been used in 500 U.S. cases. It can currently be used with nine FDA 510(k)-cleared implant partners due to THINK Surgical’s open implant library concept.

“It’s a robot, but it’s very different from traditional robotic systems,” said Stuart Simpson, THINK Surgical CEO. “It’s much smaller, easier to use and offers more choice of implants than other systems on the market.”

TJO’s Klassic One System supports 90% of joint replacements without the need for patient-specific customization, templating, additional imaging or disposables.

Workflow Improvements

TMINI is also engineered with ASC efficiency in mind, offering a streamlined workflow that minimizes operational challenges. “The device can be set up in about five minutes compared to the 20 minutes it takes to ready larger robots for surgery,” Simpson said. He noted that faster set-ups translate into faster O.R. turnover times, which are critical in outpatient settings.

TMINI’s compact design requires only one sterilization tray, significantly reducing space and cost concerns. Additionally, its CT-based preoperative planning capabilities allow surgeons to bring in only the implant size needed for each case, eliminating extensive inventory requirements. Plus, facilities get two handheld TMINI units per tracking system, with the option to add more handpieces as needed.

“TMINI is about half the price of a standard robot and with our two-for-one system, facilities can perform back-to-back cases seamlessly,” Simpson said.

THINK Surgical’s open implant library allows surgeons to select from multiple implant brands and alignment strategies while maintaining a consistent way of performing surgery. “Surgical teams can follow the same workflow every time, no matter the implant or surgical technique, and they love that,” Simpson said.

OrthAlign’s Lantern handheld devices also fit neatly into existing workflows. “The box that Lantern units come in is about the size of a college textbook and weighs less than seven ounces,” Aldrich said. “It really plays to the efficiency and size requirements of ASCs.”

Lantern’s disposable navigation unit simplifies sterile processing, and an intuitive design allows surgeons to quickly calibrate its systems and begin procedures. Patient registration can be completed in under a minute and post-procedure cleanup is minimal.

“Our technology fits into any surgical workflow,” Aldrich said. “The navigation unit is disposable, and the mechanical items are sterilized with the other items from the case. That makes it practical for a facility that does one total joint case a week or hundreds. The devices are easily scalable without creating an operational challenge.”

Scott Emami, Vice President of Marketing at Total Joint Orthopedics (TJO), highlighted the company’s Klassic One Knee System’s Modern Universal Femur, which includes advanced features like the J-Curve for optimal rollback. It also has a high flexion and a patented Double Q-angle/anterior flange to ensure proper patella tracking for left and right knees. TJO will present data at AAOS 2025 that is expected to validate the femur’s patella tracking capabilities and prove its equivalence to anatomical designs with less patellar tilt or offset.

Emami said orthopedic companies that are designing joint replacement solutions for ASC customers are focused on reducing the burdens associated with the use of multiple trays of instrumentation. The Klassic ONE instrumentation set allows surgeons to perform up to 90% of total knee replacements with only a single tray of instrumentation. It intends to simplify workflows and reduce costs, making it well-suited for the outpatient setting.

The system addresses several critical challenges faced by ASCs, including space limitations, equipment complexity and clinical efficiency. Fewer instruments entering the surgical field also reduces contamination risks and improves patient safety.

By reducing the instrumentation needed for knee replacement surgery from eight trays to one, the Klassic ONE system significantly decreases case setup and turnover times, sterilization costs and storage requirements. “ASCs can save up to $1,350 per case compared to traditional eight-tray systems,” Emami said.

The system’s small footprint minimizes O.R. clutter and maintains efficient workflows. Emami noted that research supports these benefits, with studies showing that streamlined instrumentation can cut per case preparation times by 20 minutes.

Surgeons also benefit from instrumentation that enables them to tailor the Klassic Knee implant’s alignment to individual patients and address unique anatomical challenges within a single, flexible system. This adaptability ensures high-quality outcomes for patients with varying clinical needs, from straightforward cases to more complex procedures.

TJO has partnered with open platform robotic and navigation solutions, such as OrthAlign and THINK Surgical, to enhance the versatility of its Klassic Knee System. “We provide tools and implants for surgeons who want to operate with robotic or navigation solutions,” Emami said. “Our goal is to reduce the large capital investments and space requirements that are needed to support traditional standalone systems.”

Continued Advancements

The future of orthopedic technology is poised to expand the capabilities of ASCs and redefine joint replacement care. Simpson foresees a shift to smaller, procedure-specific systems that enhance efficiency and patient outcomes. “We’re moving away from massive, multi-purpose machines toward focused, compact technology tailored to specific procedures,” he said.

Simpson also highlighted the potential of just-in-time inventory management and remote preoperative patient preparation and postoperative monitoring to further enhance outpatient orthopedic care. “Patients value convenience,” he said. “Remote technologies and patient concierge services will be critical in improving their overall experience.”

The orthopedic industry is entering a new phase of technological innovation, marked by the integration of data and artificial intelligence. This evolution signals a shift toward smarter, more accessible solutions that benefit surgeons and patients by simplifying workflows and improving outcomes. The movement could prove particularly beneficial for the outpatient market.

“We’re beyond the early focus on improving implant placement and bone cuts by a millimeter or degree,” Aldrich said. “The next step is about leveraging data to create more compact, efficient tools that reduce the costs of care and streamline operations.”

KK

Kendal Kloiber is a contributing editor.