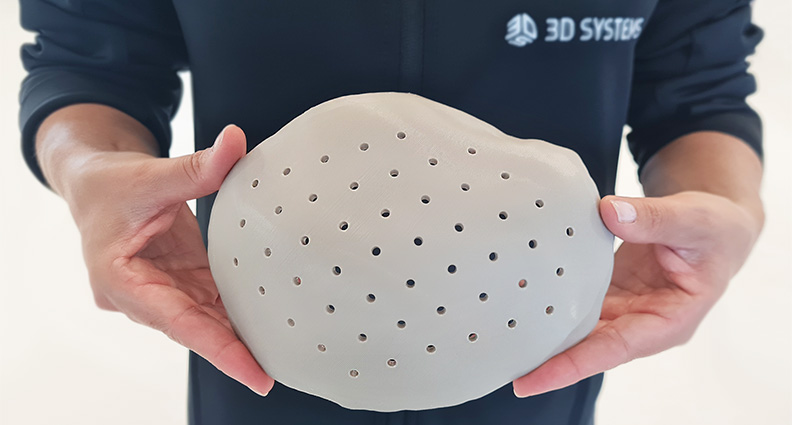

3D Systems received FDA 510(k) clearance for its 3D-printed, patient-specific VSP PEEK Cranial Implant. The system includes a complete FDA-cleared workflow comprising segmentation and 3D modeling software, the 3D Systems EXT 220 MED 3D printer, Evonik VESTAKEEP i4 3DF PEEK and a pre-defined production process.

By utilizing additive manufacturing solutions, this technology can produce patient-specific cranial implants with up to 85% less material than similar implants produced by traditional machining. Furthermore, the cleanroom-based architecture of the printer combined with simplified post-processing workflows makes it an ideal technology for producing patient-specific medical devices at the hospital site with faster turnaround while keeping the overall cost under control. To date, this solution has been used to enable nearly 40 successful cranioplasties in Switzerland at University Hospital Basel, in Austria at Salzburg University Hospital and in Israel at Tel-Aviv Sourasky Medical Center.

The VSP PEEK Cranial Implant is the first FDA-cleared, additively manufactured PEEK implant intended for cranioplasty procedures to restore defects in the skull.

Dr. Gautam Gupta, SVP & General Manager, Medical Devices, 3D Systems, said, “Our EXT 220 MED printing system has already enabled the production of nearly 40 cranial implants in support of successful cranioplasties throughout Europe. With this FDA clearance, we are now able to bring VSP PEEK Cranial Implant to the U.S. — setting a new standard of excellence for these procedures. We are now looking to the next applications for this technology, which includes 3D-printed spine interbody fusion implants, carbon fiber-reinforced PEEK for plating applications in trauma and fixation, and bioresorbable polymers for large bone and craniomaxillofacial applications.”

Source: 3D Systems

JAV

Julie A. Vetalice is ORTHOWORLD's Editorial Assistant. She has covered the orthopedic industry for over 20 years, having joined the company in 1999.