In the fast-paced world of outpatient orthopedic surgery, efficiency and innovation are paramount. Nowhere is this more evident than in ambulatory surgery centers (ASCs), where streamlined workflows and rapid turnover times between procedures keep patients moving and case volumes full.

One of the key challenges facing ASCs is managing the investment and upkeep of surgical instruments. With limited reprocessing resources compared to larger hospitals, ASCs must carefully balance budgetary constraints without compromising patient care. Streamlined instrument sets and single-use tools minimize the financial burden associated with instrument purchasing and maintenance.

“When we think of ASCs, we want to put all of the key instrumentation in the main tray, so everything that’s needed to perform surgery is at the surgeon’s fingertips,” said Rick Simmons, Chief Marketing Officer at Spinal Elements. “We’re cognizant that many ASCs might not have the same storage space and reprocessing capabilities as larger hospitals.”

Orthopedic companies are exploring streamlined instrument sets and single-use technologies to meet the unique workflow needs of ASCs with tailored solutions that prioritize efficiency, affordability and patient safety.

Less is More

Streamlined solutions reduce the instruments required for specific surgeries to simplify O.R. setups and post-procedure cleaning processes, enabling surgical teams to operate more efficiently and turn over rooms faster between cases. This enhances overall efficiencies and eliminates the need for ASC staff to reprocess multiple trays of complex instrumentation, doing away with a significant burden for outpatient facilities that run lean and mean and must maximize the productivity of each team member.

Workflow efficiencies in ASCs must not come at the expense of patient safety and excellent outcomes. Orthopedic and spine companies strive to strike a balance between reducing instrument complexity and maintaining high-quality standards. Reconfiguring standard sets to accommodate physician preferences and focusing on must-have instruments allows companies to optimize how fast surgical teams work without sacrificing how well surgeons operate.

Ortho Development’s BKS Uni Knee features simple instruments and a two-tray design.

Ortho Development launched the BKS Uni Partial Knee System last year, adding it to the portfolio of the Balanced Knee implant system. BKS Uni’s fixed-bearing implants and instruments allow surgeons to make precise intraoperative adjustments to the flexion gap to match the extension gap during unicompartmental knee replacements, resulting in efficient and consistent surgeries. Ortho Development said BKS Uni provides implants and instruments in a two-tray system that is designed specifically to streamline workflows for complex procedures performed in ASCs.

The Preserve from NextStep Arthropedix allows surgeons to perform hip replacements through the anterior approach without relying on a surgical assistant to retract tissue and muscle. This streamlined solution limits damage to soft tissue and bone, allowing patients to recover sooner, and frees up a surgical team member to focus on other more pressing clinical responsibilities — both key benefits in the ASC setting.

Last year, Anika Therapeutics introduced the RevoMotion Reverse Shoulder Arthroplasty System. CMS added shoulder replacements to the ASC-approved list in January, a perfectly timed policy change for Anika, which is well-positioned to capitalize on the growth of outpatient shoulder replacements.

“There’s an interesting dynamic at play. The companies with the most market share offer complex shoulder replacement systems that fill six instrument trays,” said Cheryl Blanchard, Ph.D., CEO of Anika Therapeutics. “Most ASCs can’t handle that level of instrument reprocessing. Several smaller companies, including ours, offer two-tray systems optimized for the ASC setting. That’s where the opportunity lies.”

ASCs haven’t been performing shoulder replacements in volume, so they need to start figuring out ways to incorporate the procedures into their workflows, Dr. Blanchard said. “We’re well-positioned to take advantage of that development,” she added. “Our timing couldn’t have been better with the release of the RevoMotion system.”

Single-use instruments are emerging as solutions to maximize workflow efficiencies and protect patients from potential infections that can occur if instruments are not properly sterilized. These instruments offer numerous advantages that align perfectly with the efficiency-focused goals of ASCs. Eliminating the cleaning and sterilization of instruments between procedures streamlines workflows, reduces O.R. setup times and helps surgical teams keep pace with a schedule stacked with cases.

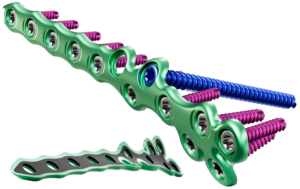

Single-use instruments and sterile-packed implants make GLW Medical Innovation’s Appollo AFX ideally suited for the outpatient setting.

GLW Medical Innovation is focused on single-use instrument solutions with the recent release of the Apollo Ankle Fracture (AFX) Plating System. Apollo AFX combines sterile-packed implants with single-use instrument kits, which feature high-grade plastics and surgical steel that are designed to assist surgeons with the precise fixation of plates and screws.

This fusion of plastic and steel promotes performance and affordability, making the system economically viable for a wide range of surgical facilities, from independent ASCs to large hospital systems.

Some single-use instruments feel cheap and flimsy. GLW Medical Innovation prioritized usability and durability in the development of its disposable instrumentation.

“The Apollo system is a great example of how we’ve taken a different approach to disposable instruments,” said Vadim Gurevich, President & CEO of GLW Medical Innovations. “The handles of the instruments are made from high-performance polymers and their tips contain surgical steel from Germany, so they provide surgeons with the performance and feel of reusable instruments.”

This core focus sets the stage for the development of Apollo AFX’s next generation of tools to bridge the gap between disposable and reusable instruments in terms of feel and performance.

Last November, Pristine Surgical announced the commercial launch of the Summit 4K single-use surgical arthroscope. The first-of-its-kind disposable device is packed sterile and ready to use out of the box, making it easy for surgical teams to set it up for surgery and eliminating the need for reprocessing after surgery.

Summit integrates with ASCs’ existing endoscopy towers, allowing facilities to upgrade to 4K without a major capital investment. Pristine Medical said Summit is available through a scope-by-subscription business model with transparent pricing, making it a cost-effective and practical solution for budget-conscious facilities. Pristine Surgical also provides recycling options to its customers through partnerships with sustainability firms.

“We developed Summit to address the challenges inherent to conventional surgical visualization, which relies on reusable arthroscopes that become obsolete, are difficult and costly to maintain and are prone to wear, damage and potential infection,” said Stephen J. Snyder, M.D., Pristine Surgical’s Chief Medical Officer. “It is a major leap forward in a field that hasn’t changed much over the past 40-plus years.”

Frontline Feedback

Simmons underscored the significance of adaptability and innovation in catering to the needs of ASCs. Spinal Elements’ commitment to developing novel technologies, such as the Karma fixation modality for degenerative spine conditions and the Orbit instrument line that is designed to help surgeons perform efficient discectomy procedures, shows their dedication to optimizing efficiency in ASC settings.

The Karma system is packaged in a single tray and features a one-size-fits-all implant, eliminating the need for space-conscious ASCs to order and store several sizes to accommodate the needs of various patients.

Simmons highlighted Spinal Elements’ collaborations with surgeons as an important aspect of the company’s development of streamlined instrument sets. The company interviewed surgeons to better understand their needs and preferences and used the feedback to maximize the efficiency and usability of the company’s instrument sets.

Spinal Elements’ reps continue to conduct vertical upstream interviews with surgeons to understand what critically important tools must be available in main instrument trays. The company breaks down spine procedures into five sequences — access, disc prep, device implantation, placement of biologics and fixation — and then determines on a percentage basis how frequently surgeons reach for each instrument in a set.

“We’re trying to get to the point of differentiating between must-have and nice-to-have instruments,” Simmons said. “We want to remove the instruments that surgeons might need during one in every 10 cases from the main trays. Surgical teams could then keep them on back tables in the O.R. so they’re accessible when needed.”

Spinal Elements also works with individual surgeons to strategically organize instruments in trays for easy access. “You’re dealing with surgeon preferences, from account to account, so we must work to meet the needs of various individuals,” Simmons said. “We often design standardized instrument sets and reconfigure the tools to accommodate physician preferences. That’s the only way around it.”

Safer Instrument Care

Gurevich said interest in single-use instruments is growing as outpatient facilities struggle with sterile processing inefficiencies or, worse, surgical site infections linked to improper instrument care. “Increasing the capacity of sterile processing departments within ASCs is not a quick or easy fix,” he said. “You’d need to pay reprocessing techs more, increase their training and revamp established processes and procedures.

“Even reusable instrumentation has engineering flaws that can lead to sterility issues. Instead of trying to invest in improving the many layers involved in sterile processing, moving to single-use instruments could be the more cost-effective and practical option.”

Recent incidents at healthcare institutions have highlighted the critical importance of effective instrument reprocessing in ensuring uninterrupted surgical services and maintaining high standards of patient care.

In October 2023, Providence Santa Rosa Memorial Hospital in California ceased most of its surgical procedures due to a water treatment concern discovered in its sterile processing department. Earlier this year, surgeons at HCA Florida North Florida Hospital in Gainesville faced a crisis of “dirty” instruments being delivered to operating rooms, leading to the temporary suspension of all surgeries. The hospital launched a “blitz” response to address the issue, including plans to construct a new temporary facility for instrument sterilization. Last January, a surprise inspection at Lancaster General Hospital in Pennsylvania revealed violations of state instrument reprocessing requirements.

Amid these incidents, the emergence of streamlined and single-use instrument sets offers a promising solution, providing healthcare facilities with tools to navigate reprocessing complexities while optimizing efficiency and patient outcomes.

Single-use instruments raise environmental concerns, but GLW Medical Innovation offers recycling services and streamlined packaging solutions to reduce waste associated with its products. For example, the Quick Caddy is a patented solution included in the Appollo AFX system that provides a single, convenient package that contains six to eight screws.

“Other companies have transitioned to sterile-packed implants and plating systems, but package each screw in individual boxes,” Gurevich said. “That’s wasteful, but it’s also time-consuming to open each box during surgery to access the screws. With the Quick Caddy, all the screws needed for a procedure are in a single, easy-to-open sterile package.”

Gurevich believes single-use instruments present a compelling option for ASCs that grapple with sterile processing inefficiencies.

“They’re a perfect solution for facilities that want to increase their clinical efficiencies and maintain a constant workflow,” he said.

KK

Kendal Kloiber is a contributing editor.