The spine market surpassed $9.8 billion in sales in 2022 and will grow to $10.9 billion by 2026, according to ORTHOWORLD estimates. Over the next few years, global procedure volumes are expected to improve, M&A integrations will continue, motion preservation technologies should gain traction and enabling technologies will enter the market.

In addition to their popularity and life-changing capabilities, spinal implants are subjected to very specific and strict surface finishing requirements to ensure longevity and fixation to bone.

Mass finishing and shot blasting play key roles in creating the right finish for spinal implants, not only for intermediate surface treatment after forging, casting, machining and additive manufacturing, but also for placing the final surface finish before implantation.

Let’s examine the capabilities of mass finishing and shot blasting for spinal implants and how Rosler can develop a precise and repeatable finishing process to meet your unique challenges and goals.

Mass Finishing

Mass finishing is a universal finishing technology that can be used for a multitude of surface treatment operations for spinal implants and instruments.

These include deburring/edge radiusing, surface cleaning/de-oiling, and descaling after casting, forging, blanking, machining, heat treatment, thread rolling for screws, and additive manufacturing.

Mass finishing is equally suitable for surface smoothing and high-gloss polishing down to Ra = 0.8 microinches.

For very critical instruments, mass finishing is a preparatory step for electro-polishing.

Typical mass finishing machines for treating spinal implants include:

- Small rotary and tub vibrators. These machines provide great results for interbody fusion cages, artificial discs, cervical plates, and spinal rods.

- Small centrifugal disk finishers. Offering high-energy systems 10 times more intensive than vibratory finishers, these machines are great for pedicle screws, spinal hooks, cervical plates, and artificial discs.

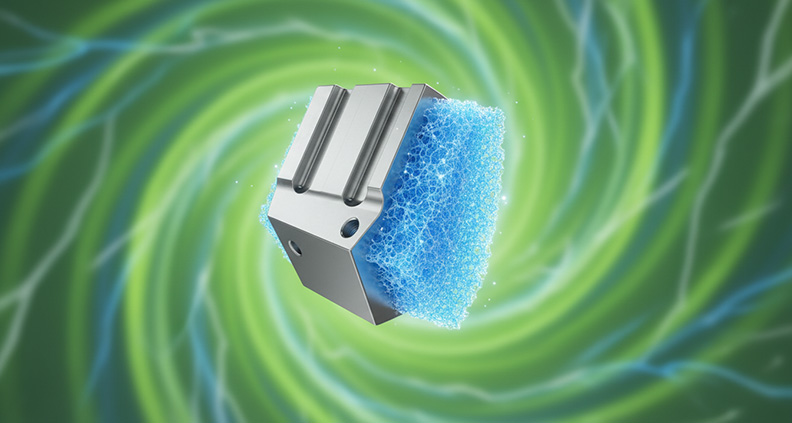

- Compact drag finishers. Perfect for finishing delicate surgical instruments and work pieces, these machines feature very high processing intensity, larger work piece capabilities, no part-on-part impingement, and extremely smooth polished finishes.

Shot Blasting

Shot blasting is an exceptionally versatile surface treatment technology that is used for deburring/de-flashing, surface cleaning (de-scaling, rust removal, and stripping of coatings), surface preparation for coating and cosmetic purposes, and even surface improvement.

With respect to spinal implants, shot blasting is primarily used for surface cleaning, surface preparation for coatings, preliminary smoothing of additively manufactured components, and shot peening.

Shot blasting is also used for cosmetic purposes such as placing a very fine matte anti-glare finish on certain surgical instruments.

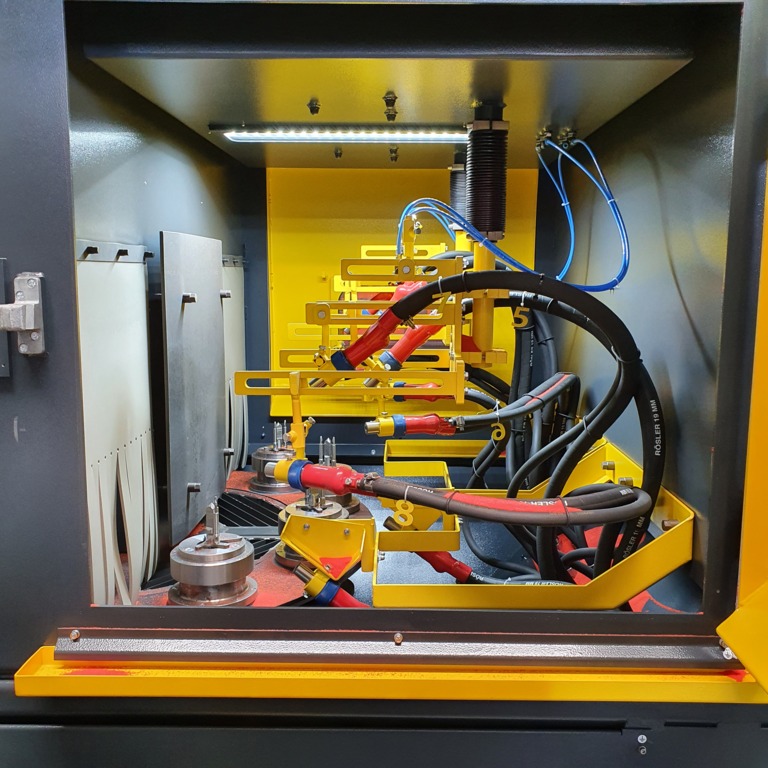

Typical shot blasting machines for treating spinal implants include air and wet blast cabinets. Customized with rotary baskets, turntables, and rotary satellite stations, these machines offer blast cleaning and deburring for screws, cervical plates, interbody fusion cages, and more.

The Rosler Way

Regardless of your spinal implant processing needs, Rosler can develop and deliver a better way to achieve precise finishing results. Contact us today to discuss your unique challenges.

Put our more than 80 years of experience to the test by requesting a free processing trial from one of our worldwide Customer Experience Centers.