Purdue University engineers have developed a laser nanotexturing process to enhance the antimicrobial properties and bone integration capabilities of titanium orthopedic implants. The discovery could reduce risks of post-op infections and decrease the number of knee replacement and spinal surgery revisions.

The first step of the process creates a nanotextured surface on implants to enhance their ability to integrate with bone cells. This treatment results in a 2.5-fold increase in bone formation compared to surfaces of untreated titanium implants.

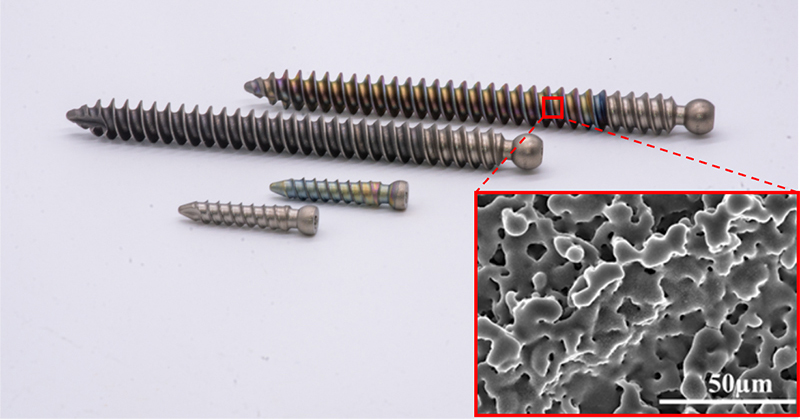

The second step immobilizes silver onto implant surfaces to reduce bacterial growth and biofilm formation. The research found that titanium surfaces treated with immobilized silver showed antimicrobial properties for more than six days against gram-positive Staphylococcus aureus and gram-negative Escherichia coli bacteria. Laser processing powers above 24 W formed hierarchical nanoporous structures on the titanium surfaces.

The researchers published a paper about their work in Langmuir: American Chemical Society Journal of Fundamental Interface Science.

“The technology immobilizes antibacterial silver compounds onto surfaces of implants and provides a unique nanotexturing that allows for better settle attachment mineralization,” said Rahim Rahimi, Ph.D., Assistant Professor in Purdue’s School of Materials Engineering and head of the research team. “These characteristics will improve implant outcomes, including less risk of infection and fewer complications like device failure.”

Device-related infections are major complications in orthopedic surgeries, said Dr. Rahimi, despite advancements in titanium and titanium-based alloys used in implants.

Standard titanium rods, plates and screws without antimicrobial properties are common culprits of post-op infections, causing orthopedic surgeons to administer prophylactic antibiotics to patients before surgery to reduce the risk. Dr. Rahimi noted that other methods used to modify implant surfaces in order to add antimicrobial properties aren’t as effective in preventing infections as nanotexturing.

“Long-term antibacterial protection is not possible with traditional drug coatings because a large portion of the loaded drug is released in a short time,” Dr. Rahimi said. “Mixtures of microbes are often found in infections associated with implants. It is essential to choose a bactericidal agent that covers a broad spectrum.”

The nanotexturing of titanium implants builds off previous research of Dr. Rahimi, who developed the laser technology to increase the antimicrobial properties of copper. “We created a robust process that selectively generated micron and nanoscale patterns directly onto the targeted surface without altering the bulk of the copper material,” he said.

Dr. Rahimi’s research team exposed bacteria cultures on copper surfaces for 90 minutes at room temperature. At regular intervals, the researchers tested the amount of bacteria present on the surfaces. They discovered that laser-treated surfaces exhibited more rapid killing of bacteria than non-treated surfaces.

Copper has long been used as an antimicrobial material, Dr. Rahimi said. However, its smooth surface makes it difficult for the metal to kill bacteria by contact, and it typically takes several hours for native copper surfaces to eradicate pathogens. “We developed the laser-texturing technique to effectively enhance the bacteria-killing properties of copper’s surface,” he explained.

Dr. Rahimi’s research then tested laser-created nanoscale surfacing on other metals and polymers, including titanium orthopedic implants. The rugged texture of the laser-treated surface creates opportunities for bacteria to hit the implant and rupture on contact.

The process’s simplicity and scalability make it applicable on several types of implant surfaces, according to Dr. Rahimi. His next goal is to incorporate the process into standard orthopedic devices. He then hopes to validate the technology for FDA approval before licensing it to companies in the orthopedic space.

Nanomaterial coatings used to increase the antimicrobial properties of metal surfaces can leach off and are toxic to the environment, according to Dr. Rahimi. Giving implants an antimicrobial surface would prevent the spread of infection and limit antibiotic resistance, he added.

He also said that nanotexturing is effective against aggressive strains of drug-resistant superbugs such as Methicillin-resistant Staphylococcus aureus (MRSA).

Dr. Rahimi has called the approach a promising candidate for novel rapid surface modification of metal implants. “The process doesn’t add antibiotics or spray coating to the surface of implants,” he said. “It simply modifies the native surface of the material to enhance its antimicrobial properties.”

DC

Dan Cook is a Senior Editor at ORTHOWORLD. He develops content focused on important industry trends, top thought leaders and innovative technologies.