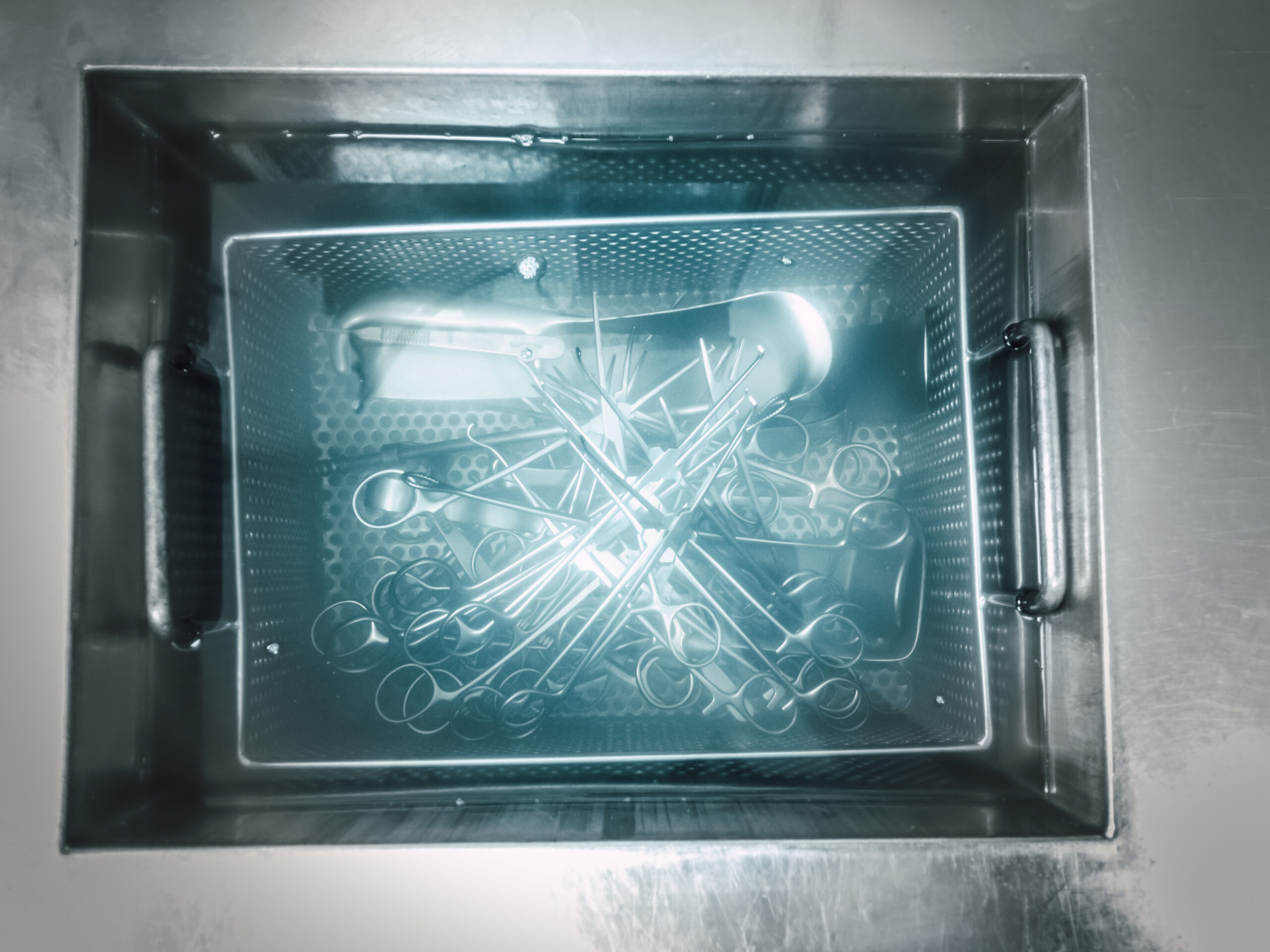

Ransohoff introduced a new modular automated cleaning system. The RBS Modular System is an automated immersion cleaning system that can be expanded to meet process requirements for medical implants and instruments.

The RBS Modular System is a dedicated inline process that includes a wash, rinse, ultrasonic wash, ultrasonic rinse, heated blow off and a final vacuum drying system. The system is set up to process parts in a basket or on a fixture. The RBS Modular System can handle parts up to 1,100 lbs (500 kg) and up to 15 cycles per hour.

RBS Modular System. Photo courtesy of Cleaning Technologies Group.

The RBS Modular System cleans using a washing and rinsing process of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. The “triple action” batch cleaning process was developed specifically to process a broad range of challenging parts, especially those with internal bores and passages and complex geometries.

The Modular RBS System offers the features of the latest Siemens programmable controller and operator interface screen. The controls platform utilizes automation integration, process control and data logging while offering an intuitive user interface.

Ransohoff is a division of the Cleaning Technologies Group LLC.