The orthopedic industry is often criticized for being slow to adopt new and emerging technologies, mainly due to an “if it’s not broken, why fix it” mentality. Commercializing a novel orthopedic product is complex, from regulatory hurdles to hospital purchasing and surgeon education. With this in mind, it’s not much of a surprise that some burgeoning orthopedic technologies are being created with ideas found outside of the medical device industry and not by sticking to the tried-and-true materials, designs and manufacturing.

From a product line inspired by heavy industry to a fascinating oceanic creature paving the way for an exciting new orthopedic treatment, some of the potentially impactful up-and-comers in the field are thinking outside of the box for fracture repair and other orthopedic applications.

Bone Fracture Adhesive

Led by orthopedic device engineer and Founder and CEO Brian Hess, RevBio is a Massachusetts-based company that studied oceanic creatures to discover a new method for repairing bone fractures. According to Hess, his keen interest in leveraging biocompatible materials to solve medical problems inspired his unconventional path.

“My interest has always been in figuring out how to solve the body’s problems with materials that are very compatible and natural to the body,” Hess said. “There are a lot of medical devices that are improving people’s lives –– orthopedic implants, for example, and pacemakers. But I always felt it would be really interesting to have materials that mimic the body, whether it’s the tissue of bone or soft tissue specifically.”

Ambitiously tasking himself with creating a fracture repair alternative with a material that the body wouldn’t reject, Hess determined that the best potential candidates for the job were calcium phosphates before focusing on oceanic creatures.

“In order to get these adhesive properties, we realized we needed to kind of think about how to glue things together underwater without using toxic materials. And so we got inspired by nature and found that there are organisms that secrete their own underwater adhesives –– mussels, oysters and barnacles on boats, for example.”

Hess eventually selected the sandcastle worm, a creature that produces the amino acid O-Phospho-L-Serine to bind sand grains together underwater. After learning to reverse-engineer the amino acid and combining it with calcium phosphate, Hess and his team discovered that the resulting material was indeed biocompatible.

Today, Hess estimates that RevBio is two to four years away from commercializing a dental application for its Tetranite bone adhesive technology. The injectable adhesive requires only a small incision to deliver the material, making it a more minimally invasive treatment option than traditional open orthopedic surgery. The company’s product pipeline includes cranial flap fixation, fracture repair, spine fusion and potentially joint replacement and suture anchor attachment.

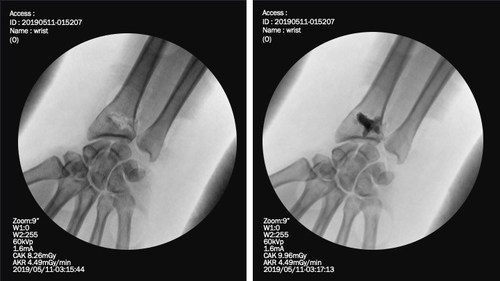

RevBio was recently awarded a two-year, $2 million Phase II Small Business Innovation Research grant to pursue the treatment of wrist fractures with its Tetranite bone adhesive technology.

RevBio’s Tetranite is a bone adhesive technology for fracture repair.

Bone Fixation Interface

While RevBio found success looking to nature as the foundation of its fracture repair product, OsteoCentric adapted an idea from heavy industry to inspire its suite of orthopedic products. Headquartered in Austin, Texas and founded in 2015, the medical technology company is working to create the Gold Standard for bone implant interfacing in orthopedics.

“By name, OsteoCentric is bone-centered,” said Gavin Sontag, the company’s Chief Marketing Officer, “which means we are hyper-focused on the way bone interfaces with implants in all areas of orthopedic, dental and veterinary surgery.”

OsteoCentric pioneered a relatively simple and low-tech solution to a problem most innovators in the industry are failing to address. The current standard for securing implants leaves room for better outcomes for the stability, preservation and overall health of a patient’s bone. UnifiMI, the company’s proprietary mechanical integration technology, is a less invasive method to instantly secure an implant to bone utilizing an interlocking thread geometry.

“UnifiMI is rooted in technology that originated outside of the medical space. The original concepts, intellectual property, and problem-solving mentality were adapted from heavy industry and then used to solve systemic problems in the interface between implants and bone,” Sontag said. “Our patented bone preparation and thread geometry technology (UnifiMI) allow implants to circumferentially interlock with adjacent bone. This facilitates a functional and structural connection between the two and also facilitates increased stability and load sharing throughout an implant or construct.”

OsteoCentric recently secured $30 million in funding led by Squadron Capital and OnPoint Advisors to expand its new product introductions. OsteoCentric expects UnifiMI to be applicable across spine, joint replacement, sports medicine, extremities, veterinary, limb salvage and dental implants.

Resorbable Metal Screws

To create its bioresorbable RemeOs Screws, the Finnish orthopedic device company Bioretec looked inside the body rather than at what comparable companies were doing.

“RemeOs is a resorbable metal based only on Magnesium, Calcium and Zinc, which all exist naturally in the human body and are essential for new bone growth,” said Kimmo Lähteenkorva, Bioretec’s Chief Technology Officer. “This makes the RemeOs material safe and extremely biocompatible.”

Bioretec created its screws using only elements that are found within the body. The makeup of RemeOs Screws is different from conventional metal screws that are made from materials that are foreign to the body, such as Yttrium, Gadolinium or Neodymium. The body-friendly technology received a nod from FDA when the Agency recently awarded Bioretec with a Breakthrough Device Designation, which grants higher prioritization of the device’s official review and offers eligible companies special feedback.

Conventional metal screws are associated with a host of drawbacks and complications that range from higher healthcare costs to longer recovery periods for patients, Lähteenkorva said.

“Often implants based on conventional non-resorbing metals have to be removed in additional surgery. They might cause some biocompatibility-related long-term tissue reactions, disturb or even halt bone growth in pediatric patients, or just cause plain discomfort to the patients. On the other hand, existing bioabsorbable polymer implants are currently not suitable for biomechanically demanding applications.”

RemeOs Screws completely resorb into the bone in two to three years and eliminate the need for secondary removal operations. This saves both the patient and the healthcare system significant time and costs, said Lähteenkorva, who added that RemeOs products also include a bioactive feature that promotes the natural healing process and new bone formation.

Though RemeOs technology isn’t yet available on the commercial market, a clinical study of the product has produced “outstanding” results, according to Lähteenkorva. In the study, Bioretec’s proprietary screws were used to repair medial malleolar fractures.

“As early as 12 weeks post-surgery, all the fractured bones were completely healed, and during the follow-up period of one year,” Lähteenkorva said. “No adverse events or complications have been observed in any of the patients tested.”

With promising innovations like these, Bioretec, RevBio and OsteoCentric are proving that there’s plenty of room for change and improvement within the orthopedic industry. The adoption of new ideas in orthopedics might be slower than that of other industries, but these exciting fracture repair technologies show that change is not only inevitable, but also essential.

PM

Patrick McGuire is a BONEZONE Contributor.