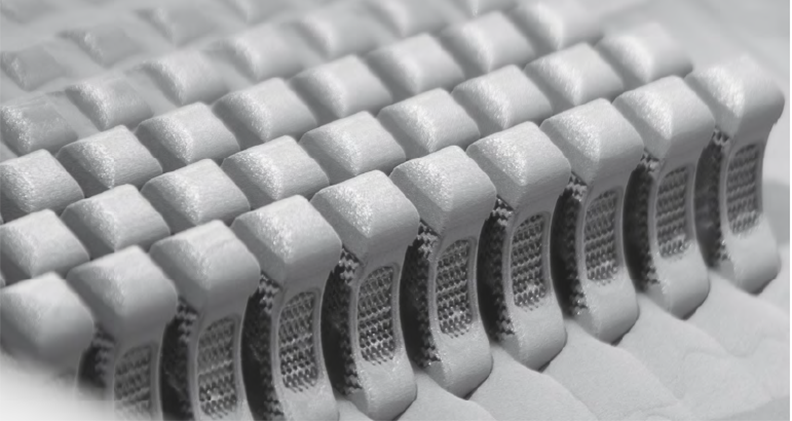

Additive manufacturing is being used to implement new design concepts and features to spinal implants. Additive offers a unique opportunity to increase the value of spinal cages without necessarily adding costs or manufacturing time, as various structures and new features are fabricated in the same manufacturing process. Additionally, today’s additive technologies combine the advantages of early titanium or PEEK approaches for spinal cages (the biocompatibility of titanium with the desired elasticity of PEEK in one component), while at the same time eliminating the drawbacks of both approaches.

This white paper by GE Additive reviews the design and manufacturing advantages that Direct Metal Laser Melting (DMLM) and Electron Beam Melting (EBM) offer spine companies producing next-generation implants.

Submit This Form to Download the White Paper

*We respect your privacy. By completing this form, you are choosing to provide us with personal information which we will share with the sponsoring company. Under no circumstance will we lease, sell or share your information with any other person or entity.