Viant completed a more than $8 million expansion at its Orthopedic Implant and Coating Center of Excellence in Chaumont, France. The expansion includes a new building with a controlled-environment room and an investment in vacuum plasma spray (VPS) coating technology that recently received approval from FDA.

The in-house VPS coating capability will enable the application of titanium coatings or a dual layer of titanium and hydroxyapatite (HA) coatings that are applied to orthopedic implants such as hips, knees and shoulders. This new VPS capability complements the Chaumont facility’s existing HA coating capabilities.

Viant’s investment includes a new 8,600-square-foot building and an ISO Class 9-equivalent, controlled-environment room with the new VPS torch and related equipment, as well as operations including grit blasting, shot peening and surface finish measurement and inspection.

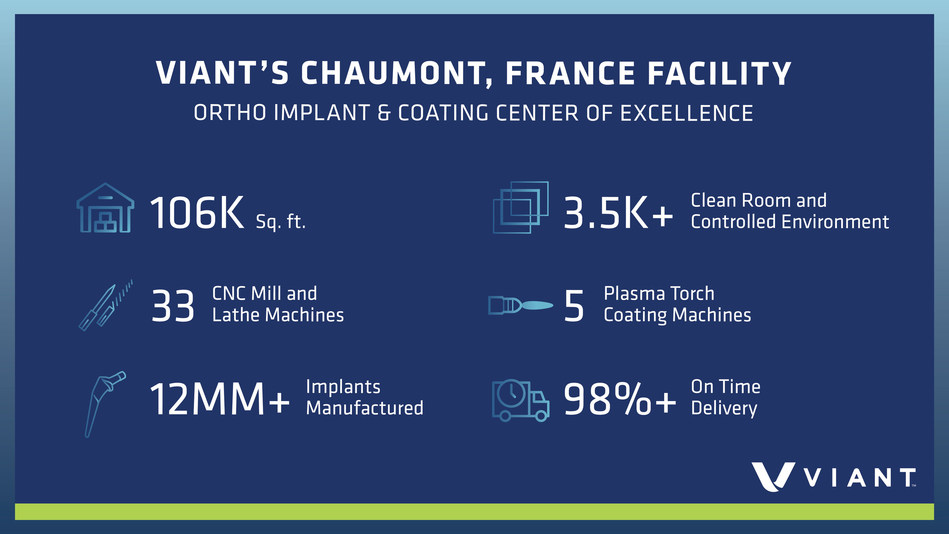

Viant’s Chaumont, France Facility

Viant’s vertically integrated Chaumont facility has more than 30 years of experience transforming raw materials into products ready for the operating room. It features:

- Metal and plastic machining & fabrication

- Polishing

- Subassembly

- Cleaning

- Laser marking

- Coating

- Assembly

- Sterile packaging

- Microbiology laboratory